7

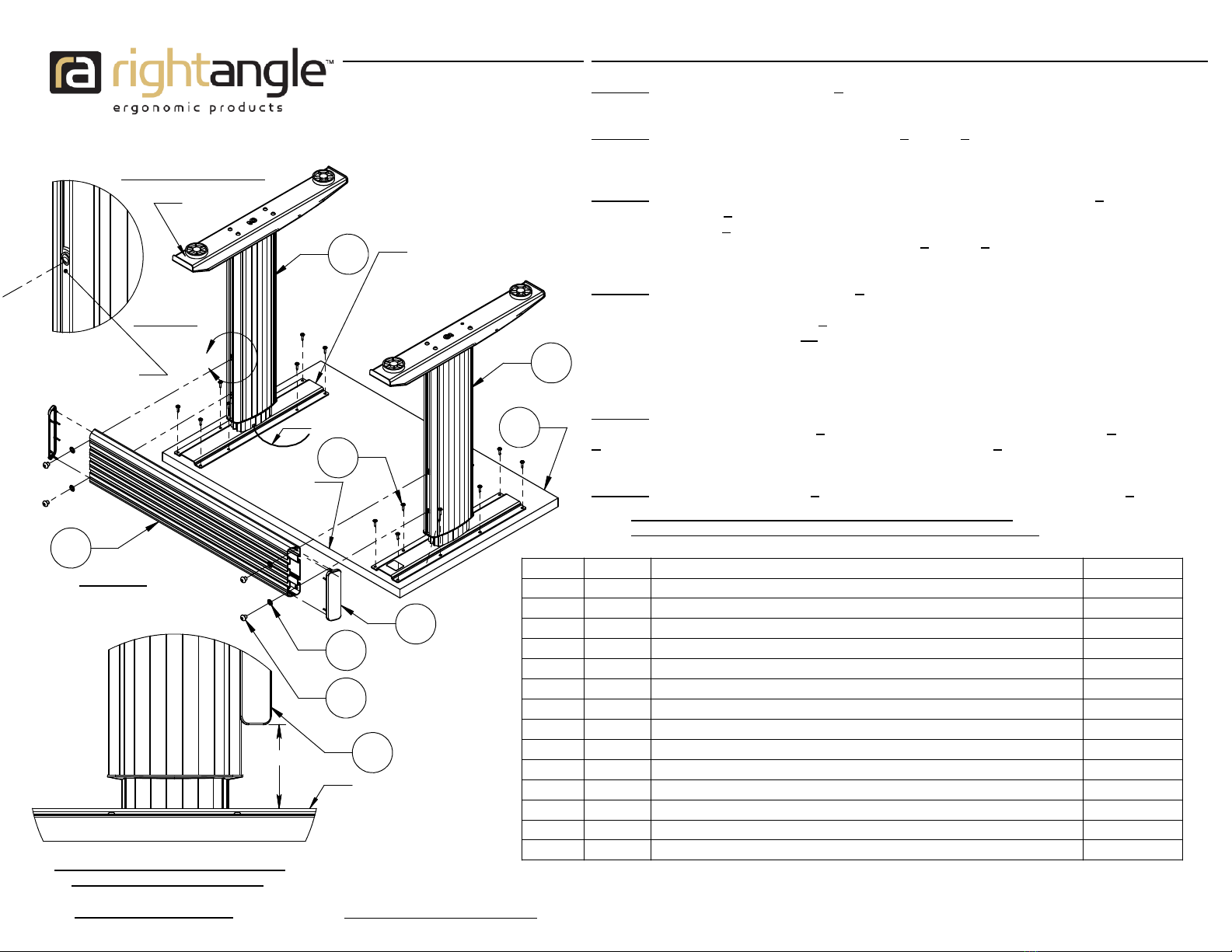

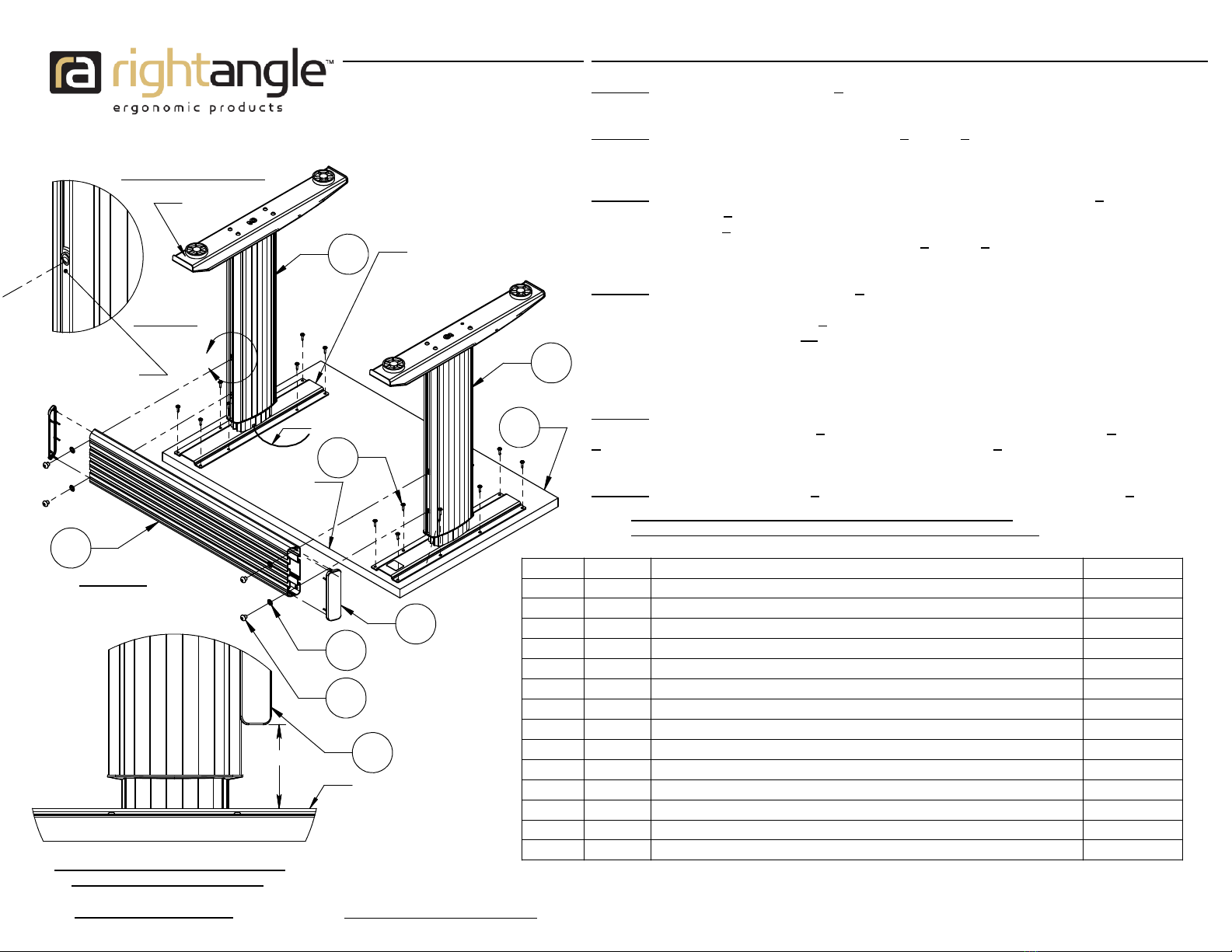

. ATTACH THE COLUMN ASSEMBLIES

PAGE 1 OF 3

. DO NOT OVER-

STEP 4: AT 4" FROM THE BOTTOM OF THE

CORDLESS DRILL WITH

DETAIL A

. INSERT THESE THROUGH THE HOLES ON EACH END OF THE

. USE THE HEX HEAD DRIVER BIT OR THE

FULLY TIGHTEN.

STEP 6:

TIGHTEN THE SOCKET SCREWS

* 1 ON 60" OR 2" WORKSTATION

.

INSERT (2) END CAPS

LEVEL

1

WORKSURFACE SUPPORT AS SHOWN IN THE DETAIL BELOW LEFT AND FULLY

WRENCH

SPECIAL EXCEPTION: ON WORKSTATIONS ON

AND THREAD THEM INTO THE HOLES IN THE T-SLOT PLATES

ALLEN WRENCH PROVIDED

ALLOW FOR CLEARANCE OF THE EQUIPMENT.

5

8

#2 PHILLIPS HEAD DRIVER BIT OR

CROSS SUPPORT

AND

/32" HEX HEAD BIT OR ALLEN

STEP 5:

TO THE WORKSURFACE USING (16) WOOD SCREWS

*** ONLY ON 60" OR 2" WORKSTATIONS

5

** 1 ON 60" OR 2" WORKSTATION

2

32

3

PRE-INSTALLED IN THE COLUMN ASSEMBLIES

. INTO THE ENDS OF THE CROSS SUPPORT

TAPE MEASURE

VERSION DATED: 9/8/11

. SEE DETAIL A. DO NOT

WHICH THE LifeBalance STATION IS BEING INSTALLE , THE CROSS SUPPORT

DO NOT OPERATE THE UNIT UNTIL IT IS FULLY ASSEMBLED.

TIGHTEN THE SCREWS. USE A LOW TORQUE SETTING ON THE DRILL.

14

LEVEL THE CROSS SUPPORT

TOOLS RE UIRED FOR ASSEMBLY:

4

4

ALIGN THE HOLES IN THE WORKSURFACE SUPPORTS WITH THE PILOT

AND

4

INSTRUCTION # 50591

READ ALL OF THE INSTRUCTIONS BEFORE BEGINNING

#2 SQUARE HEAD DRIVER BIT

HOLES IN THE WORKSURFACE

SHOUL BE ATTACHE RESTING ON THE FEET OF THE COLUMN ASSEMBLIES TO

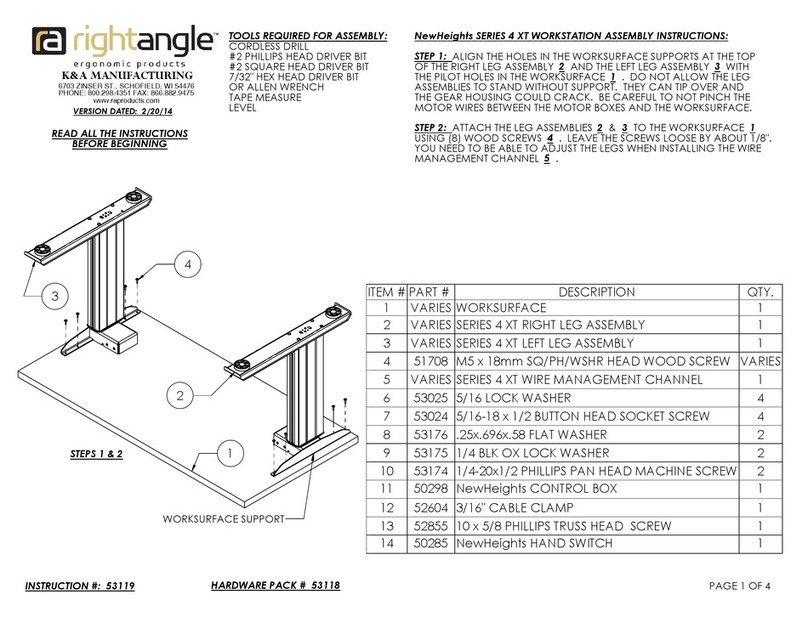

NewHeights ELECTRIC HEIGHT ADJUSTABLE WORKSTATION ASSEMBLY INSTRUCTIONS:

STEP 1: LAY THE WORKSURFACE 1 ON A PROTECTED SURFACE WITH THE PILOT

HOLES FACING UP.

STEP 2: PLACE THE COLUMN ASSEMBLIES 2 AND 3 ON THE WORKSURFACE

WITH THE FEET FACING UP. THE MOTOR WIRES MUST FACE THE INSIDE OF THE

WORKSTATION.

STEP 3: WITH THE HELP OF AN ASSISTANT, PLACE (4) STAR WASHERS

6 ON (4)

SOCKET SCREWS

ITEM # PART # DESCRIPTION QTY.

1 VARIES WORKSURFACE 1

2 VARIES NewHeights COLUMN ASSY LEFT HAND 1

3 VARIES NewHeights COLUMN ASSY RIGHT HAND 1

4 VARIES NewHeights CROSS SUPPORT 1

5 524 0 3/8-16 x 3/8 BUTTON HEAD SOCKET SCREW 4

6 524 3/8 INTERIOR TOOTH STAR WASHER 4

800411 NewHeights/HOVER END CAP 2

8 51 08 M5 x 18mm SQ/PH/WSHR HEAD WOOD SCREW 19 OR 1 *

9 50285 NewHeights HAND SWITCH 1

10 500 2 8 x 3/4 PHILLIPS PAN HEAD RECEX DRIVE SCREW 4

11 51951 WIRE MANAGEMENT J 3 OR 1 **

12 VARIES 42" OR 54" U-CHANNEL 1 ***

13 52498 /32" ALLEN WRENCH 1

14 50298 NewHeights 2-LEGGED CONTROL BOX 1

6703 ZINSER ST., SCHOFIELD, WI 54476

PHONE: 800.298.4351 FAX: 866.882.9475

.raproducts.com

K&A MANUFACTURING

FOOT

5

STEPS 1-6

1

MOTOR WIRES

SUPPORT

WORKSURFACE

8

BACK

3

4

6

2

A

LOCATING THE CROSS SUPPORT

4

(SEE EXCEPTION IN STEP 4)

BOTTOM OF

WORKSURFACE

SUPPORT

HARDWARE PACK # 52226

4.00

PRE-INSTALLED

T-SLOT PLATE