6

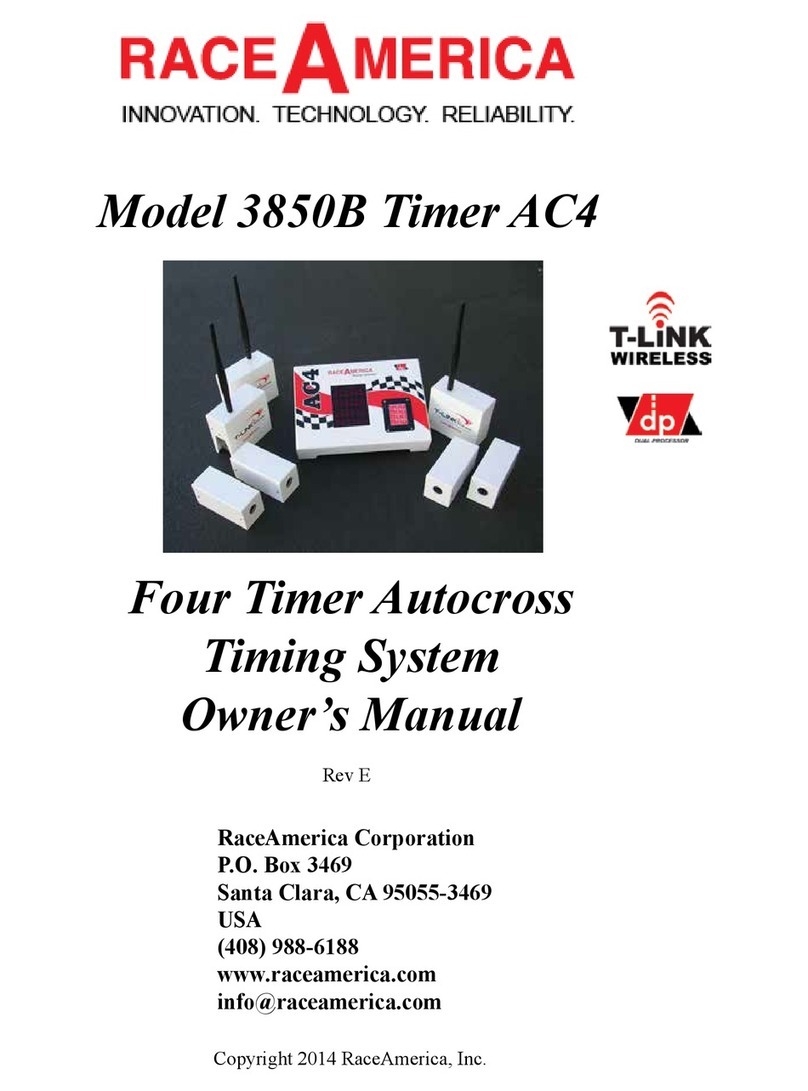

RaceAmerica Model 3850 Timer AC4

Keypad functions for each mode are described

in this manual.

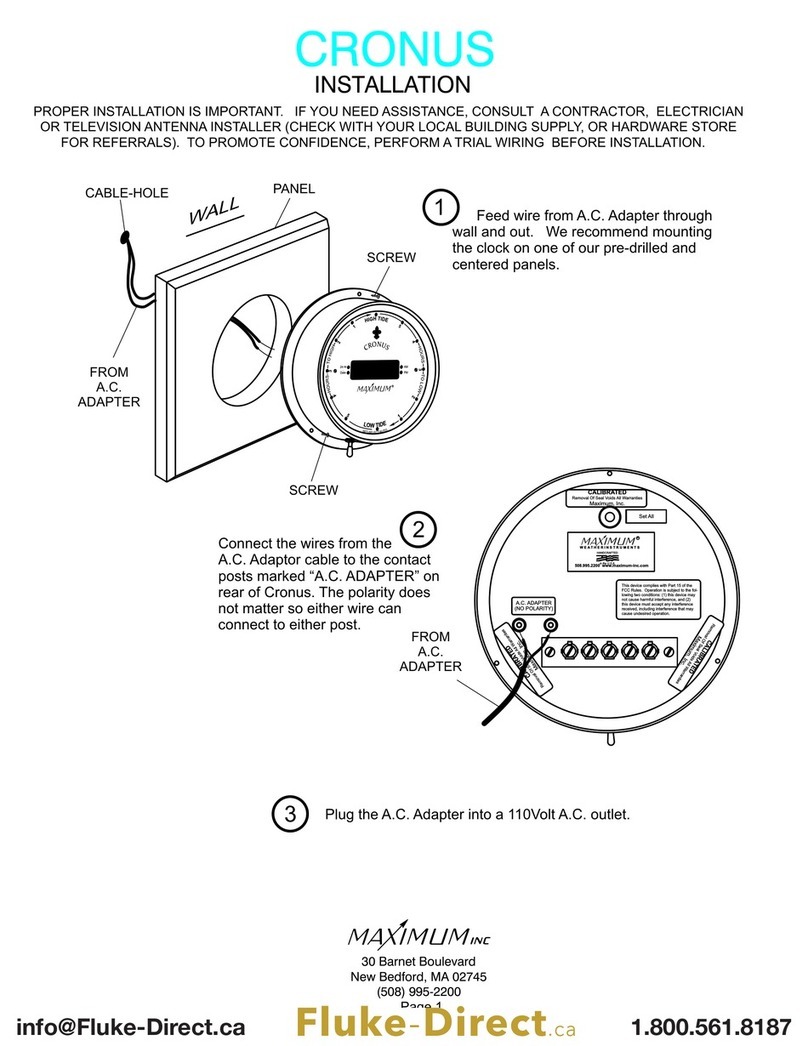

SET-UP STEPS - WIRELESS TIMER

Place the ‘A’ unit at the Start and the ‘B’ unit

at the Finish per diagrams (Fig 4 or 5). Positioning

the antenna(s) as high in the air as possible will

optimize performance.

Power on a T-Link and observe the LED

illuminates alternating between red and green, .

If the battery charge is at minimum charge, the

T-Link will power o even if the power switch

is ON. When T-Links are powered on, the LED

will ash green when a wireless signal is received.

During normal operation, the LED on each T-Link

will ash red during transmit and ash green each

time signal is received from another T-Link.

The *4 CONFIG menu in Fig 11 is used

to configure the timer for single/dual sensor

operation, minutes/seconds display, sensor lockout

times, printer conguration and timslip header

printing. See the full CONFIG properly set up

and aligned on the racing surface, the timer console

will continue to ‘monitor’ the track sensor at the

start line to start the next timer or at the nish line

to stop the next timer (lap-timer uses only the start

beam).

NOTE: once the start or nish line beam

is interrupted, the system imposes a two to nine

second lockout (see CONFIG menu) of that sensor

to allow blowing debris to settle. During the

last second of the lockout, the system performs

alignment testing of the triggered sensor to

determine if the alignment has changed. Failure

of the starting line beam alignment is indicated

by ashing [StArt] [SEnSor] [test] [fAiLEd].

[Finish] [SEnSor] [tESt] [FAiLEd] would

indicate the nish line alignment has failed testing.

These messages are displayed until another

message updates the Status Display. This feature

helps in early detection and resolution of a low

battery in the Beam Emitters, someone tripped

over a cable, or a sensor has been bumped out of

alignment.

NOTE: Once all four timers are actively

counting, any additional interruption of the start

line beam will not start a new timer until one of the

current timers is stopped by a nish line crossing

or manually stopped via the keypad (Wired only).

Install the antennas on all T-Link units. If the

antenna has been bent down for transport, loosen

the antenna slightly and rotate the upper portion

of the antenna into position. Hold the upper

portion of the antenna while tightening the knurled

area on the bottom portion of the antenna. The

antenna should point in the vertical direction and

be o the ground by eight to ten feet for optimal

performance.

STEP 1 -

Familiarize yourself with the Components

pictured in this manual and how they interconnect.

Track Sensor Cables are used to connect the

starting line and nish line to the timer console

or T-Link Wireless units (Fig. 1 thru 6).

All connectors are keyed for proper

orientation. The 12VDC battery is connected

with the RED alligator clip to plus (+) terminal

of the battery and the BLACK alligator clip to

(-) terminal of the battery. Do not connect to an

operating motor vehicle! Optional 110/230VAC

adapters can also be used instead of a battery.

The free standing, battery powered Model

5040/5050 IR Beam Emitters are placed on the

end of the start line and nish line away from

the timer console and the Model 5140 IR Track

Sensors are placed on the console side of the start

line and nish line. Each of the Beam Emitter and

Track Sensor units are fully interchangeable with

each other. The Track Sensor cables plug into

their respective start and nish connectors on the

underside of the console.

If the T-Link Wireless option is used to

connect the track sensors, follow set-up per the

diagrams (Fig 3 or 5).