4

Owner’s Manual: 05025X1

1786850 Rev L

ECO 17-0032

Feb 2020

www.radiaproducts.com (PHONE) 800-221-1083 | (INTL) +1-763-533-2969 | (FAX) 763-533-0015

- Machine must be properly grounded before use; improper grounding could

cause electric shock and injury.

-Disconnect power cord before servicing, cleaning or removing any cover,

and follow lockout/ tagout procedures in owner manual; failure to disconnect

power could cause electric shock and injury.

-Review Owners Manual before installing or operating.

- La maquinaria debe ser apoyada correctamente en el suelo antes de usar, el

no apoyarla puede casuar choque elêctrico y daños.

-Desconecte la energía antes de dar mantenimiento, limpiar o quitar caulquier

cubierta, y siga los procedimientos de bloqueo/etiquetado del manual, Fallar

en desconectar puede causar choque eléctrico y daños.

- Revise el manual del usuario antes de instalar u operar.

- La machine doit e'tre correctement mis a' la terre avant de les utilizer mise

a' la terre incorrecte peut provoquer un choc e'lectrique et de blessure.

- De'branchez le cordon d'alimentation avant de proce'der a'l'entretien,

le nettoyage ou le retrait des capots: suivez la proce'dure d'isolation/

consignation proce'dures dans le manul de l'opre'rateur; E'chec de

de'brancher la source d'alimentation peut provoquer shock and e'lectrique blessyres.

-Re'examiner le fonctionnement manuel avant l'installation.

WARNING

ADVERTENCIA

AVERTISSEMENT

Part No. 1781570

NOTICE

1. POSTION CONTAINER PROPERLY?

2. ATTACH THE BAIL SPRING?

3. TIGHTEN CLAMP SECURELY?

BEFORE RUNNING MACHINE, DID YOU...

IMPORTANT MAINTENANCE ITEMS

WEEKLY

WEEKLY

WEEKLY

EVERY 6

MONTHS

EVERY 6

MONTHS

AS NEEDED

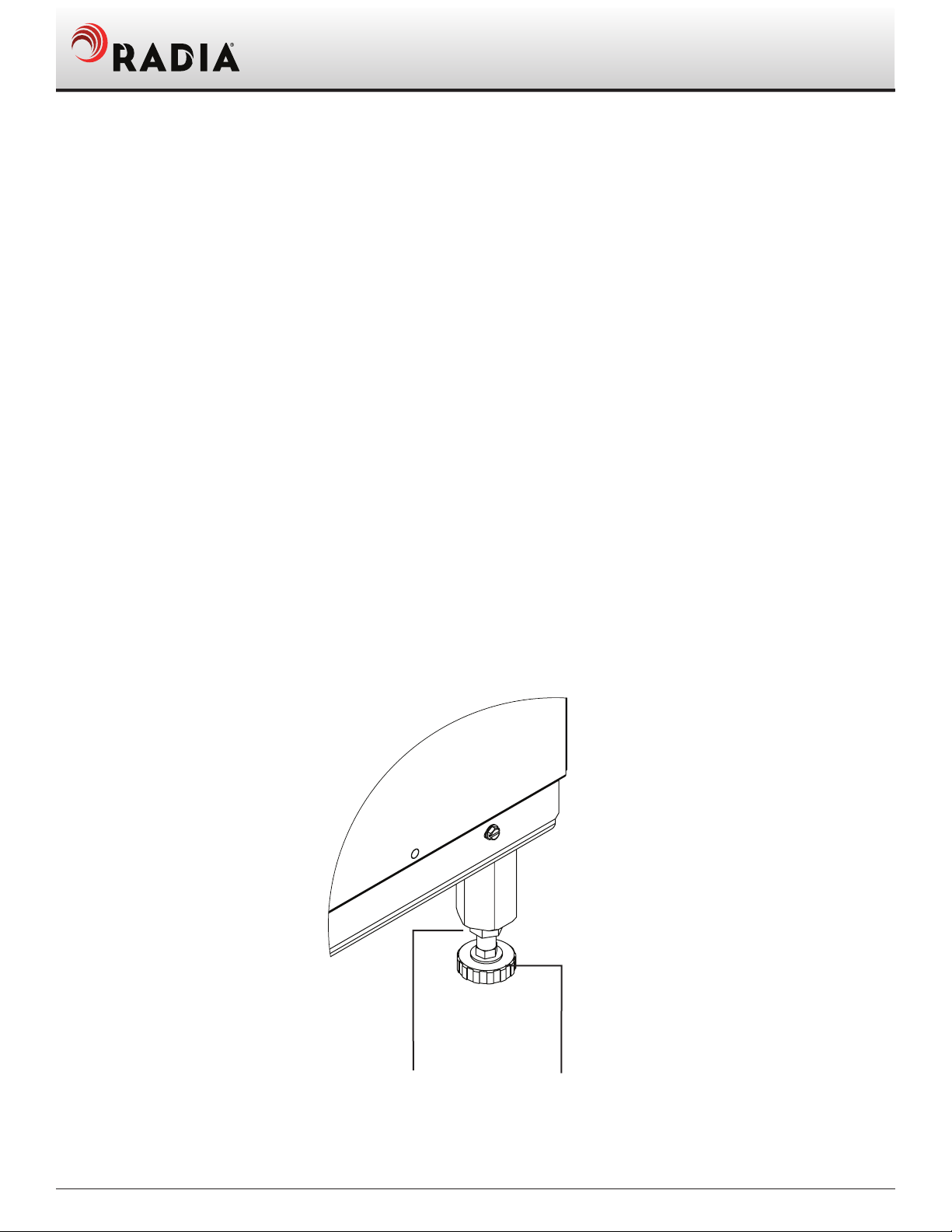

CLAMP

RELESE LEVER

THRUST

BEARING

BOTTOM PLATE

CLAMPING

SCREW

GREASE ZERKS

VERTICAL

SLIDE TUBES

ITEM MAINTENANCEFREQUENCY

LUBRICATE SHAFT WITH 3 IN OIL

TURN ROTATING ASSBEMLY UPSIDE DOWN AND

LUBRICATE ALL AROUND OUTSIDE EDGE OF

THRUST BEARING WITH 3 IN 1 OIL.

CLEAN OFF PAINT WITH HOT

SOAPY WATER.

GREASE WITH STANDARD MUlTI-PURPOSE

LITHIUM BASED GREASE, TWO SQUIRTS PER

ZERK ONLY, OVER GREASING WILL CAUSE

PREMATURE FAILURE OF BEARING.

GREASE WITH STANDARD MUTI-PURPOSE

LITHIUM BASED GREASE AS NEEDED.

CLEAN OFF DIRT AND PAINT

WITH HOT SOAPY WATER

Part No. 1784000

1.1 Safety Precaution Labels1.1 Safety Precaution Labels

Part No. 1784462

NOTICE

DO NOT OVER -TIGHTEN!

Tighten clamp up to 1/2 turn

after contact with pail lid.

Part No. 1784963

MOVING PARTS INSIDE

PARTES EN MOVIMENTO

PIE'CES EN MOVEMENT

-Do not open door until machine comes to complete stop;

moving parts inside could cause serious injury.

-No abra la puerta hasta que la marquina se detenga

completamente, las partes internas en movimiento pueden

causar heridas graves.

- Ne pas ouvrir la porte avant que la machine ne s'arrête

complètement. Pièces en mouvement à l'intérieur

pourraient provoquer des blessures graves.

WARNING

ADVERTENCIA

AVERTISSEMENT

Safety Information, Continued..