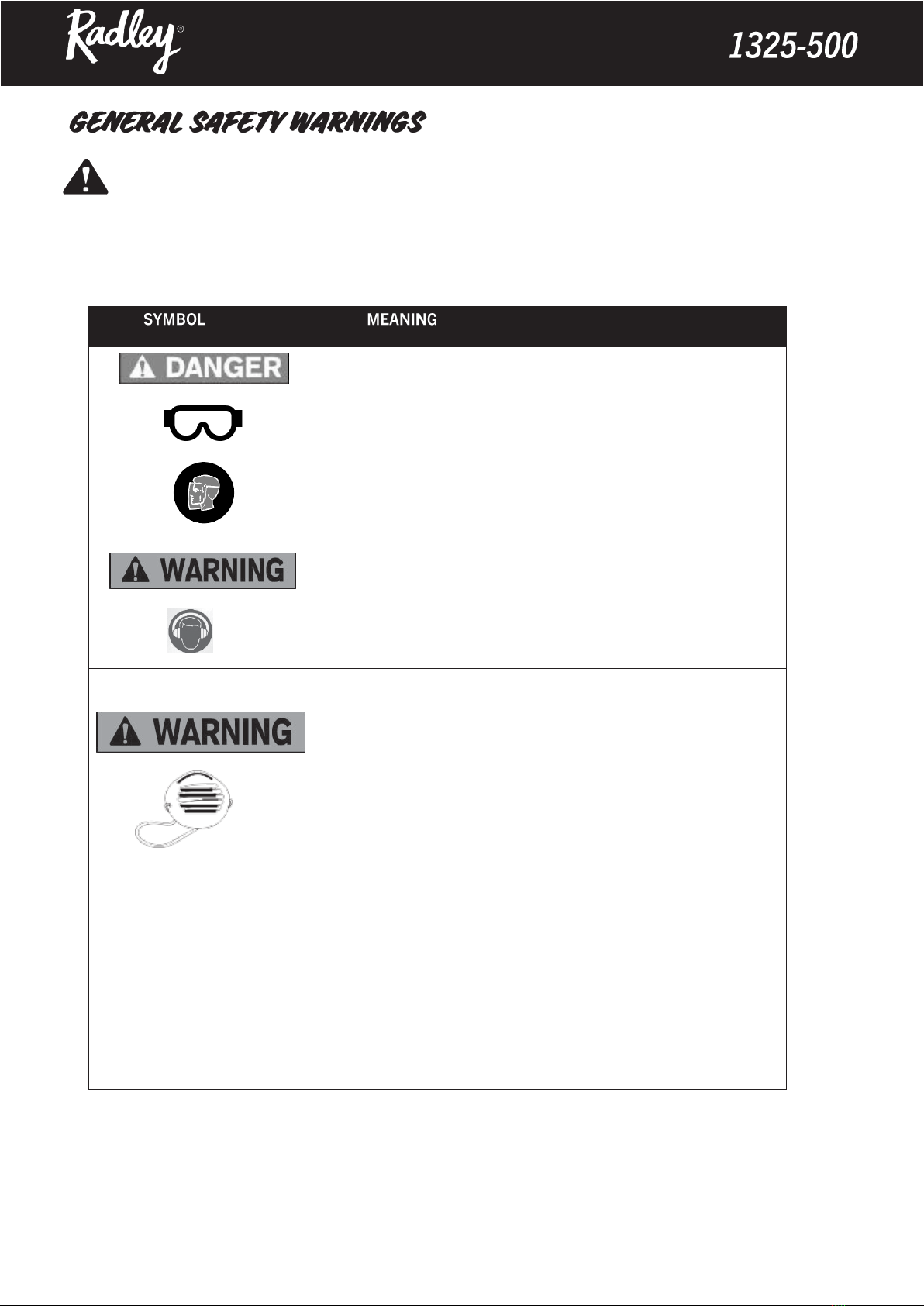

WARNING! DO NOT let comfort or familiarity with product (gained from repeated use) replace strict

adherence to the tool safety rules. If you use this tool unsafely or incorrectly, you can suffer serious

personal injury.

DANGER! When the tool is in operation, keep hands away from the saw blade and the area it is being applied to.

Failure to follow this warning will result in amputation, serious personal injury or death.

Do not operate with any guard disabled, damaged, or removed. Moving guards must move freely and close

instantly.

Never operate the grinder with broken wheels. The grinding wheels operate at 3 450 RPM. A broken wheel

could turn into a missile.

Never leave the tool running while unattended.

Avoid unintentional starting. Prepare to begin work before turning on the tool.

Never stick an object against a wheel to stop the grinder. Let it slow on its own.

Always use the tool rest and safety guard. Supports and guards are essential for safe grinder operation.

Use only properly sized wheels. The wrong sized wheel can dangerously increase or decrease operating speed

at the

grinding surface. A wheel that is too large could come in contact with the wheel housing, potentially damaging

the machine.

Do not overtighten wheel nut.

Always wear eye protection. The grinder can throw off sparks and tiny metal shards. Use eye protection to avoid

operator injury.

Adjust tool rest properly. The grinder has the potential for binding against a workpiece introduced at an

improper angle - and send it flying. Avoid grinding your workpiece at angles greater than 90。to the direction

of wheel travel.

Allow grinder to reach full speed. Let the grinding wheel reach its full operating speed before using the grinder.

Secure grinder. Attach the grinder firmly to your benchtop. Secure attachment will ensure your grinder will not

move when operated.

Avoid overheating workpiece. Excessive or prolonged grinding on a workpiece can heat it to the point where it

becomes dangerous to the operator. Excessive grinding can also soften your workpiece and ruin its edge.

Never grind small stock. Do not attempt to grind or sharpen anything that cannot be adequately supported by

the tool rest. Use clamping pliers or a similar holder when grinding parts which cannot be held easily by hand.

Keep a clean work area. The chances of an accident are far less if the area around your grinder is kept free of

clutter.

Avoid loose fitting clothing and tie back long hair. A grinder’s spindle, spinning at 3,450 RPM, can suck a

tremen-dous amount of material in a very short time - given the chance. Don’t give it the chance.

Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other

accessories running over the rated speed can fly apart and cause injury.

Never start the tool with a person in line with the wheel. This includes the operator

Do not operate the grinder near flammable liquids, gases or dust. Sparks or hot chips from grinding may ignite

combustible materials.

Maintain labels and nameplates on the tool. These carry important safety information. If unreadable or missing,

contact Harbor Freight Tools for a replacement.

WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities,

contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are: Lead from lead-based paints, Crystalline silica from bricks and cement or

other masonry products, Arsenic and chromium from chemically treated lumber. Your risk from these exposures

varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a

well ventilated area, and work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

WARNING! Handling the cord on this product will expose you to lead, a chemical known to the State of California

to cause cancer, and birth defects or other reproductive harm. Wash hands after handling.