5

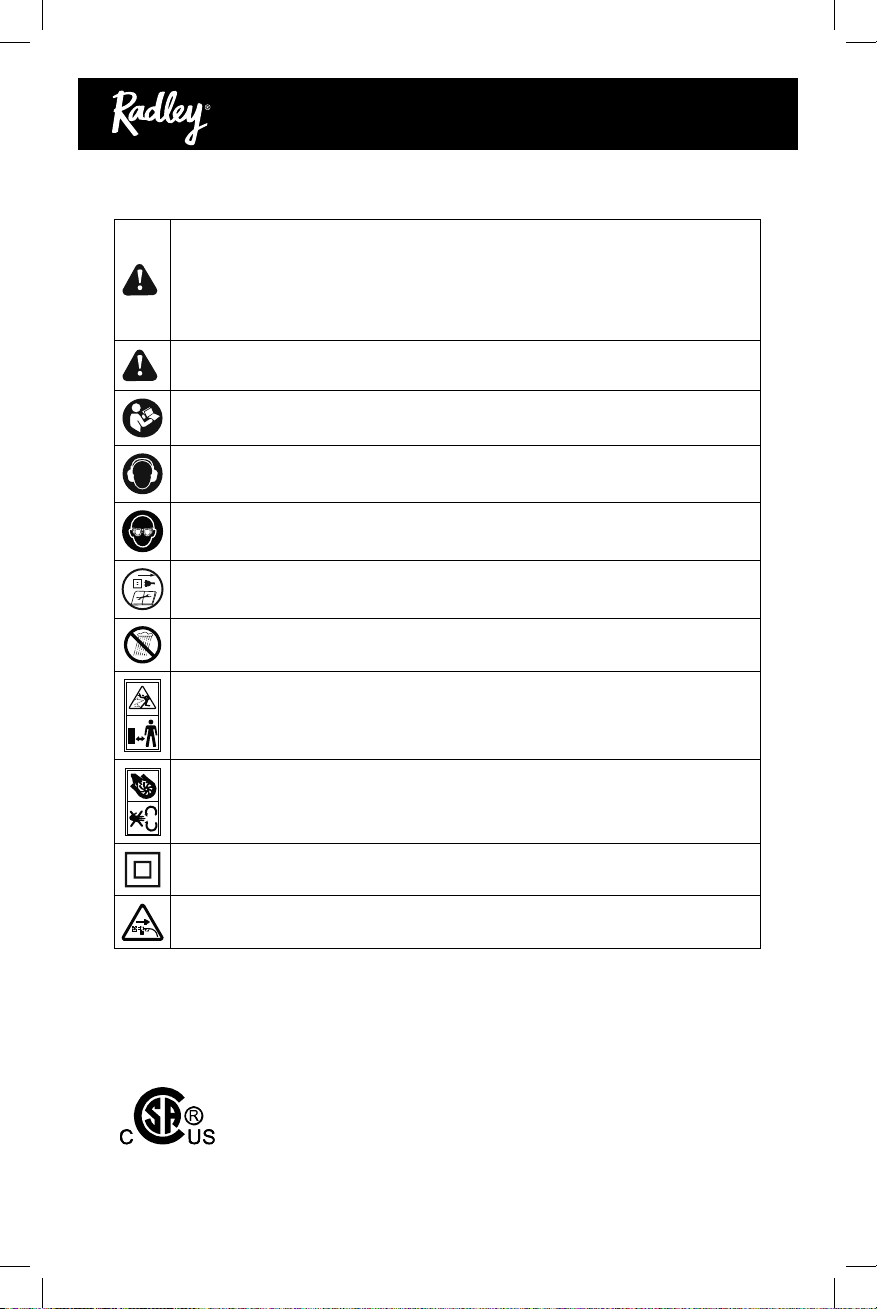

WARNING:

OWNER’S MANUAL.

TRAINED OPERATORS ONLY.

DANGEROUS ENVIRONMENTS.

MENTAL ALERTNESS REQUIRED.

ELECTRICAL EQUIPMENT INJURY RISKS.

DISCONNECT POWER FIRST.

EYE PROTECTION.

WEARING PROPER APPAREL.

HAZARDOUS DUST.

HEARING PROTECTION.

REMOVE ADJUSTING TOOLS.

USE CORRECT TOOL FOR THE JOB.

AWKWARD POSITIONS.

CHILDREN & BYSTANDERS.