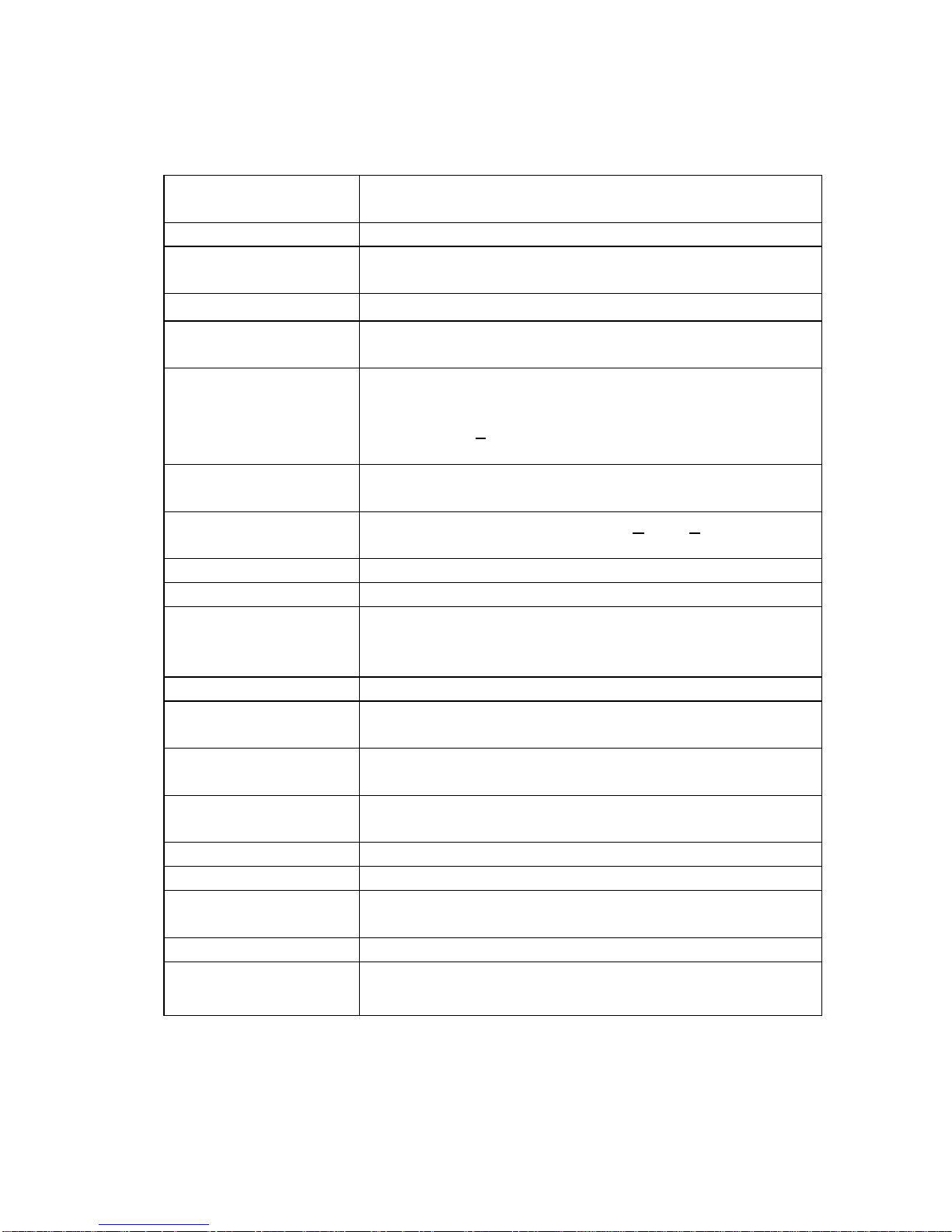

RAEGuardSEC / LEL / IR User’s Guide

1. General Information

RAEGuardSEC The RAEGuardSEC is a fixed electrochemical

detector for oxygen and toxic gas (CO, H2S, SO2, NO, NO2, Cl2, O2,

ClO2, NH3, PH3, HCN and ETO). It operates with voltages from 9 to

36 VDC and provides an analog (4 to 20mA) output signal and digital

(RS-485, ModBus) output signal within the corresponding ranges of

gas detection. The RAEGuardSEC uses an interchangeable

electrochemical smart sensor, which can be pre-calibrated

independently offline. Housed in an explosion-proof enclosure, the

RAEGuardSEC is equipped with a local digital display of the gas

concentration and unit of measurement, status LEDs, and function

keys for performing calibration.

RAEGuardSIR The RAEGuardSIR is fixed non-dispersive infrared

(NDIR) detector for hydrocarbon combustible gases, carbon dioxide,

and other gases, It operates with voltages from 9 to 36 VDC and

provides an analog (4 to 20mA) output signal and digital (RS-485,

ModBus) output signal within the corresponding ranges of gas

detection of 0 to 100% LEL or 0 to 50,000 ppm CO2. The RAEGuardS

IR uses a smart NDIR sensor, which can be pre-calibrated

independently offline. Housed in an explosion-proof stainless steel

enclosure, the RAEGuardSIR is equipped with a local digital display

of the gas concentration, status LEDs, and function keys for

performing calibration.

RAEGuardSLEL The RAEGuardSLEL is a fixed, highly poison-

resistant catalytic bead lower explosion limit (LEL) sensor for

combustible gases detection. It operates with voltages from 9 to 36

VDC and provides an analog (4 to 20mA) output signal and digital

(RS-485, ModBus) output signal within the corresponding range of 0

to 100% LEL. The RAEGuardSLEL uses a smart LEL sensor, which

can be pre-calibrated independently offline. Housed in an explosion-

proof stainless-steel enclosure, the RAEGuardSLEL is equipped with

a local digital display of the gas concentration, status LEDs, and

function keys for performing calibration.

3