Page 3

2. Legal informaon

VITO AG

Eltastrasse 6

78532 Tulingen (Germany)

Phone: +49 (0) 7461 / 96289-0

Fax: +49 (0) 7461 / 96289-12

www.vito.ag

CEO:

Andreas Schmidt (MBA, Dipl.-Wirt.Ing)

Headquarters: Tulingen, Germany

Reg. court: Stugart HRB-750227

In cooperaon with:

University Albstadt-Sigmaringen (Germany)

- Industrial engineering with business studies -

Jakobstrasse 1

72458 Albstadt (Germany)

Copyright © VITO AG

All rights reserved

This document is subject to the copyright of VITO AG.

Without previous wrien permission of the company VITO AG the

document or parts of it may neither be duplicated, nor used in

contradicon to their legimate interests.

Changes in the sense of the technical progress are reserved.

3. Preface

Dear VITO customer,

Thank you for choosing this product by VITO AG.

Please read the manual carefully to familiarize yourself with the handling of your VITO oil lter system to ensure proper use.

Your local dealer and our customer service are available to answer your quesons and provide support.

We are thankful for comments and suggesons concerning the VITO oil lter system and / or user manual. (Please nd contact

informaon in chapter 2 Legal informaon.)

We hope that you enjoy your VITO oil lter system for a long me and increase the eciency in your establishment.

With VITO you own a high-quality oil lter system from which you can expect a long life and ecient support on the fryer.

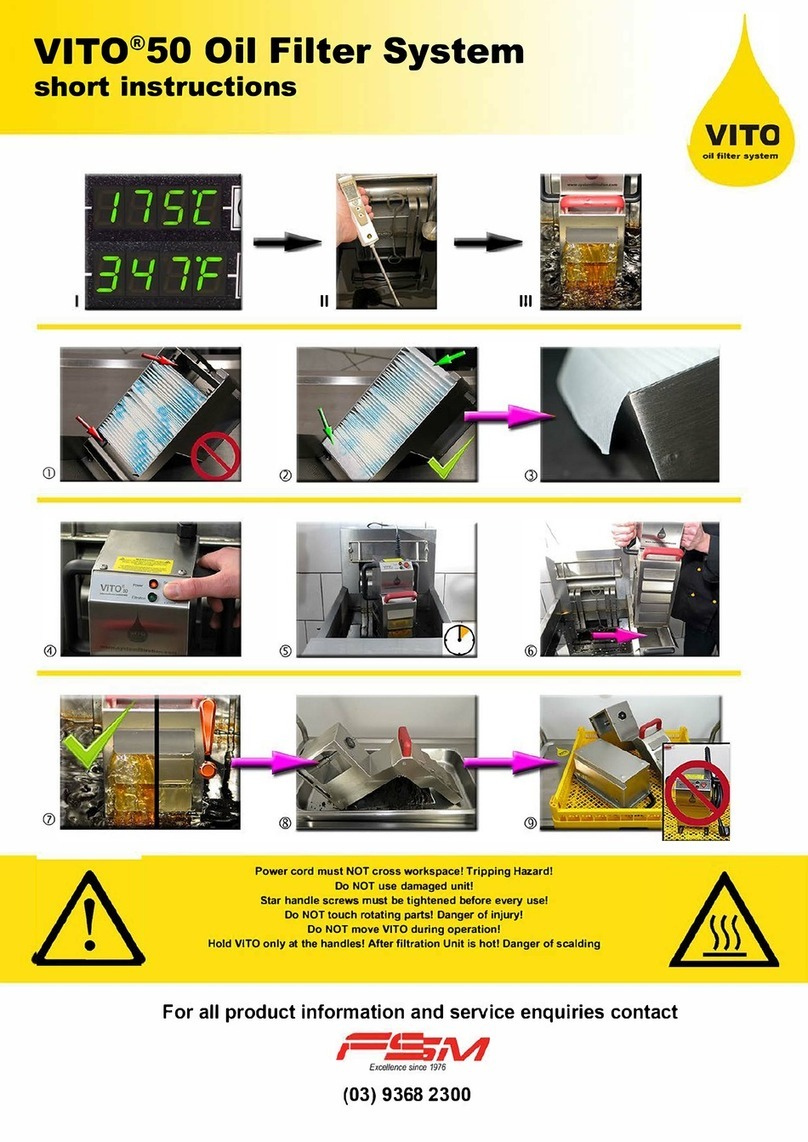

4. Safety instrucons

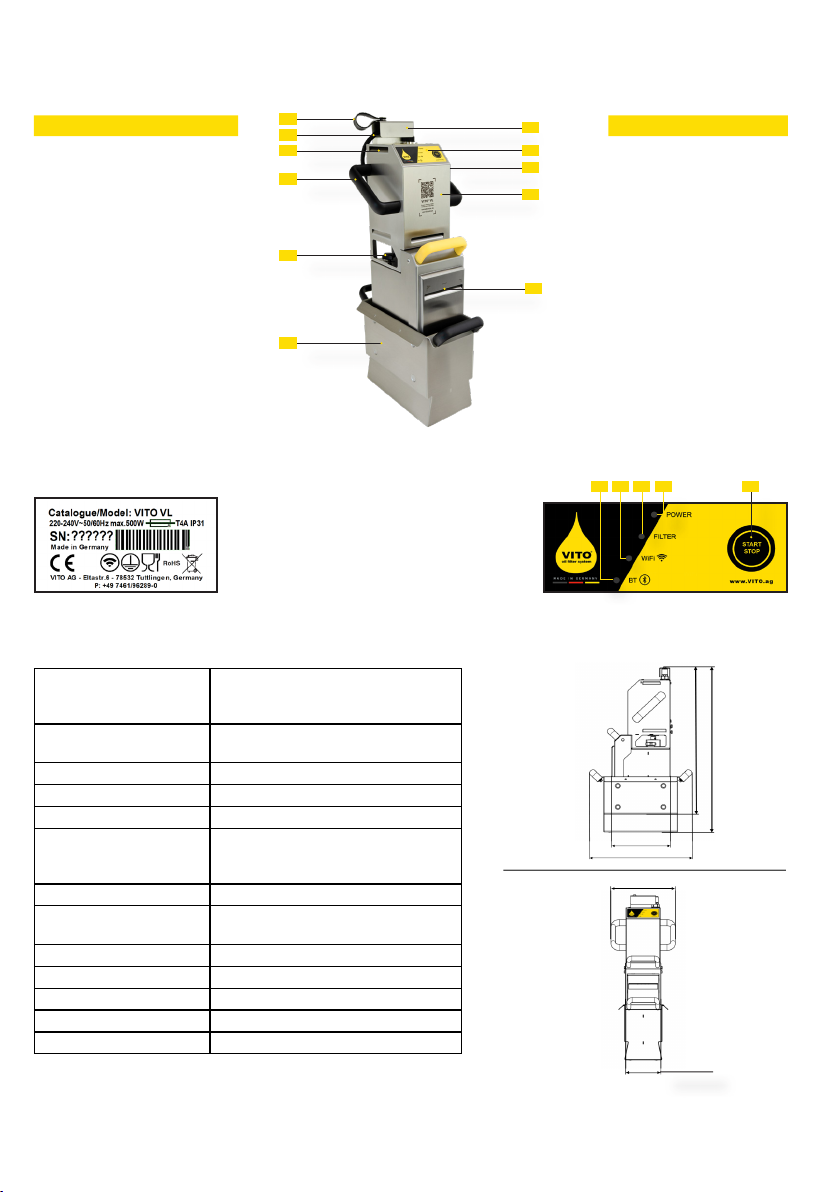

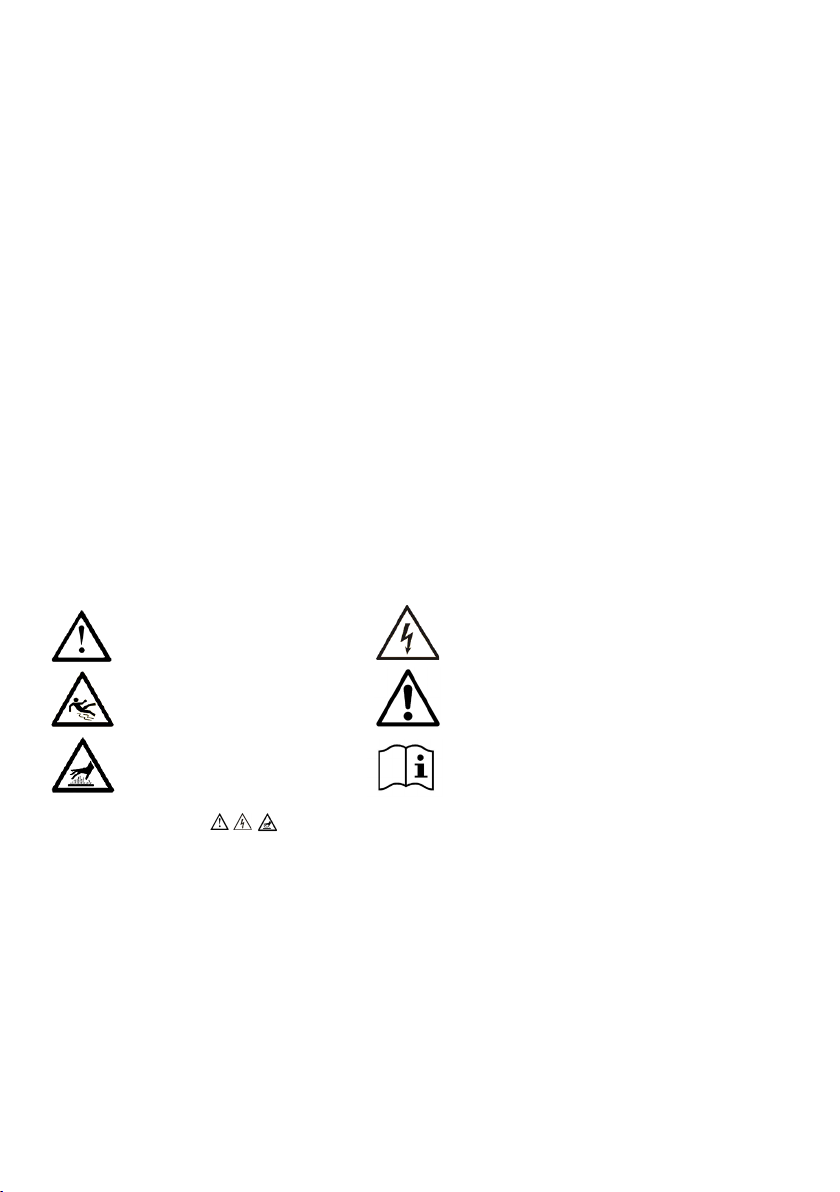

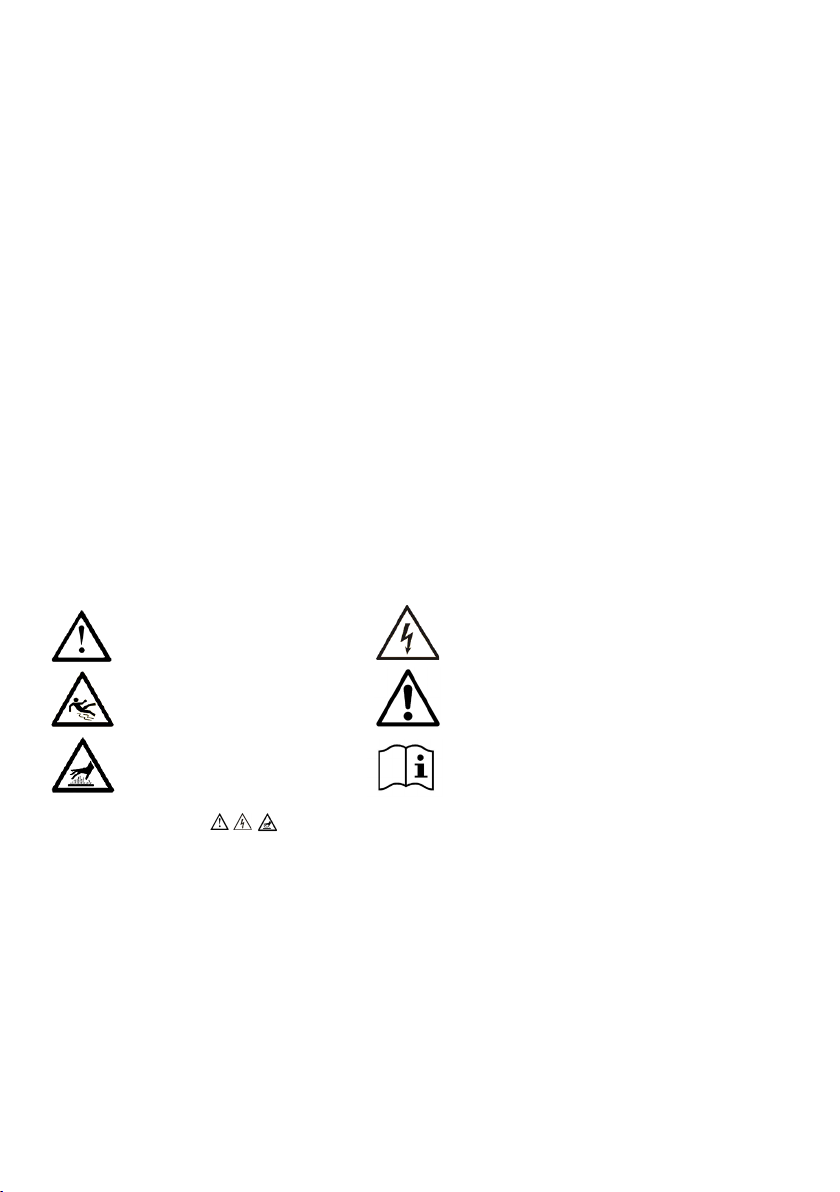

4.1 Explanaon of symbols

Incorrect operaon of the VITO can lead to danger and injury. The following should be observed.

Possible dangers are marked with these symbols:

Warning

Risk of injury if not observed

Risk of electric shock

due to incorrect handling or

opening of the housing

Risk of slipping

Contaminaon on the oor possible

Cauon

Important safety instrucon

Danger of burnings

due to incorrect operaon of VITO

Operaon instrucons

Informaon on the operaon of VITO

4.2 Safety instrucons

• VITO is NOT approved for ltraon of liquids other than frying oil.

• DO NOT use or store VITO outdoors! Damage due to rain or moisture.

• VITO is NOT designed for connuous operaon! (Risk of overheang/re).

• Children are strictly prohibited from using VITO!

• DO not cover the venlaon slots (12)!

• DO NOT touch the power cord (10) and control unit (8) with wet hands!

• DO NOT pinch or bend the power cord (10)!

• Avoid the power cord (10) to come into contact with hot oil or other hot objects.

• Operate VITO only on protecon class I connecons (with protecve earth contact).

• Clean VITO before inial use (see chapter 10 Cleaning).

• The local voltage must match the voltage on the type plate (16).

• The maximum operang temperature is 200°C / 392°F (recommended frying temperature 175°C / 347°F).

• DO NOT run the pump-lter unit (11) while dry!

• Pay aenon to heang elements, grids or thermal sensors of the deep fryer!

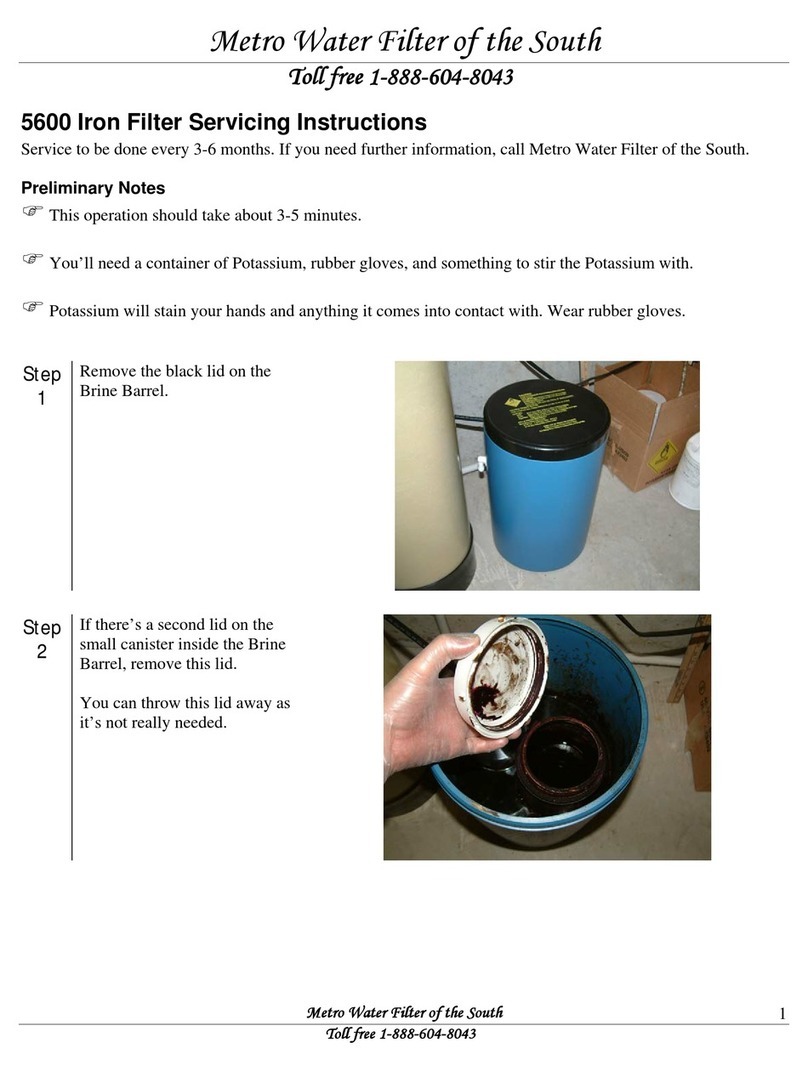

• Carry VITO only using the black handles (9)!

• DO NOT operate the VITO in an inclined posion!

• DO NOT move VITO during ltraon!