RESIDENTIAL VZN

9

P/N 1011586 Rev A 07/20

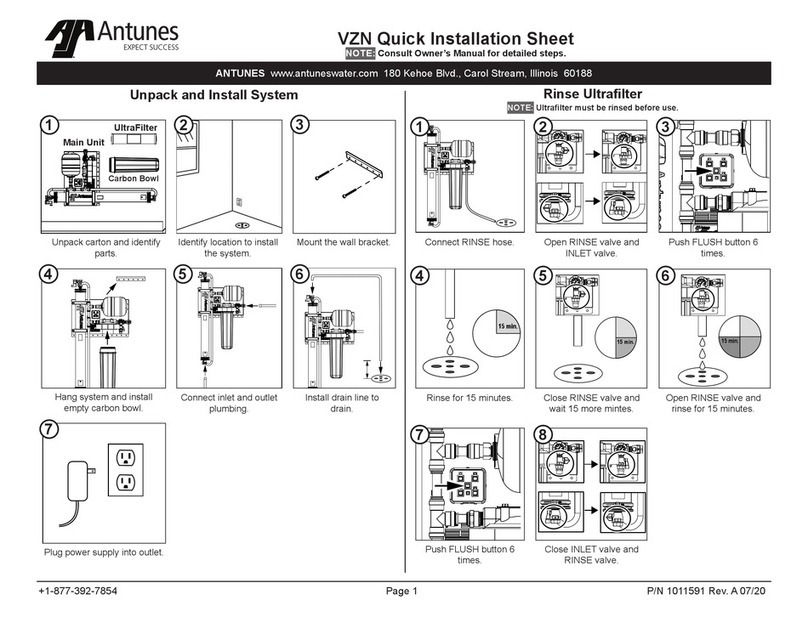

Installation

Mounting the System

NOTE: Use caution when lifting and

mounting the system. The

system MUST be mounted

using the provided Mounting

Bracket.

The VZN system comes with a Mounting

Bracket. When mounting the system, pay

attention to the following guidelines:

yAllow sucient access for cartridge

replacement. The VZN-520H

system should be mounted with

23 inches to the left or right of the

system. The VZN-540H system

should be mounted with 43 inches

to the left or right of the system

yMount the system near but

NOT above an appropriate

electrical outlet.

yMount the system near a drain

for ushing operations.

yMount the system before all

consumable water

ltration processes.

ySecure the Mounting Bracket

provided with the VZN system

into wall studs with heavy duty

hardware capable of supporting

120lbs. Or more (Mounting

Hardware Not Supplied).

yMount the VZN system to the

Mounting Bracket and secure with

heavy duty hardware (Mounting

Hardware Not Supplied).

The system is pre-assembled to a Back

Panel. The Back Panel has mounting

holes across the bottom portion to secure

the bottom of the system to the wall.

Some of the bottom mounting holes

may be obscured. Plan your mounting

accordingly.

Follow these steps to secure the

Mounting Bracket to the wall and seat the

VZN system:

1. Use a stud nder and level to attach

the Mounting Bracket securely to the

wall with the appropriate mounting

hardware (Figure 2).

2. The Mounting Bracket is designed

so that the VZN system can be lifted

and hung on the Mounting Bracket.

With assistance, lift the system and

seat it onto the Mounting Bracket

securely (Figure 2).

3. After mounting the VZN system to

the Mounting Bracket, secure the

VZN system to the wall using the

mounting holes provided on the

lower portion of the VZN system

back panel.

Alternative Vertical Mounting

The system can be mounted vertically if

required. See Figure 2A for more details.

Note the following when mounting a

system vertically.

1. Install the Mounting Bracket

horizontally as shown in Figures 2

and 2A.

2. The system must be mounted so the

Solenoid Valve is located at the TOP

(Figure 2A).

3. Allow sucient access for cartridge

replacement. VZN-420 units should

be mounted with 20 inches above

or below. VZN-440 units should be

mounted with 40 inches above or

below.

Figure 2. Mounting the System

A

32

31

31

20

28

36

21

22

23

35

23

22 21

39

39

39

39

39

3239

39

INLET ENDCAP ASSEMBLY

43

DETAIL A

SCALE 1 : 2

SEE DETAIL "B"

FOR INSTALLATION

DETAIL OF ITEMS

21, 22, AND 23

20

28

36

21

22

21

22

23

39

39

NOTE ORIENTATION

OF ITEM 28 PRIOR TO

INSTALLATION INTO

ITEM 20

23 43

B

32 32 31

31

20

21

22

23 34 12

21

22

23

39 39 39

39

39

37 38

39

DRAIN ENDCAP ASSEMBLY

5. INSTALL ITEMS 21, 22, AND 23

INTO PORT 1 OF ITEM 20.

6. INSTALL ITEMS 21, 22, AND 23

INTO PORT 2 OF ITEM 20.

7. ATTACH ITEM34 TO ITEM 12 BEFORE

INSTALLING INTO PORT 1 OF ITEM 20.

43

DETAIL B

SCALE 1 : 2

20

21

22

23

34

21

22

23

39

39

39

ITEM 21 STEP 1:

PRESS O-RING INTO

PLACE AGAINST STEP

ITEM 22 STEP 2:

PRESS O-RING GUIDE WITH

THE BEVEL FACING OUTWARDS

ITEM 23 STEP 3:

SNAP COLLET INTO

PLACE

43

NOTES:

1. ASSEMBLE PARTS AS SHOWN.

2. APPLY PIPE TAPE ITEM 39 AND THREAD SEALING

COMPOUND ITEM 38 TO ALL PIPE THREADS AS NOTED.

3. APPLY LUBRICANT ITEM 40 TO ALL O-RINGS. ENSURE

ALL ARE SUFFICIENTLY GREASED.

4. MAKE SURE END CAPS ITEM 20 (2X) ARE ATTACHED TO

HOUSING ITEM 19 BEFORE ATTACHING HOUSING ASSEMBLY

ITEM 19 TO BACK PLATE ITEM 1.

C1

C2

D1

REV

DATE

PCO NO.

DESCRIPTION

BY

D

06/11/20

PC-14371

D1 ADD ITEM 43 & D2 ADD NOTES

RC

C

11/25/19

PC-14371

C1 WAS 3250103; C2 QUANTITY WAS 4 EA

RC

ITEM

PART NO

DESCRIPTION

QTY.

1 0509346

BACKPLATE, VZN 520/540, HORIZ

1

22180215

TANK-EXPANSION, 2.1 GAL WITH 3/4 NPT

1

30400381

GROMMET, 1.75OD X 1.187 ID

1

42190158

FEMALE CONNECTOR, 3/4 CTS X 3/4 NPS

1

50012357

UNIVERSAL PULSE CONTROLLER ASSY

1

62010199

TUBING, BENT, 90 DEGREE

1

72180287 CLAMP, UFL HOUSING 2

8 3000116

NUT RETAINER - 1/4"-20

4

9 3250195

SCREW, HEX CAP 1/4-20 X 7/8"

4

10 3250154

WASHER, Ø1/4" HELICAL SPRING LOCK

4

11 3250104

WASHER, FLAT - 1/4"

4

12 4040189

VALVE, SOL NC, 24VDC, 3/4 NPT

1

13 2010247 TUBING, PEX-B, 3/4" CTS, 180°, 4.53" X 3.843 2

14 2190155

UNION TEE, 3/4" CTS

2

15 2010246

TUBING, PEX-B, 3/4" CTS, 19.72" STRAIGHT

1

16 4060438

CABLE TIE 36" BLACK

2

17 2120286

SPACER, RUBBER, 4" SS UF HOUSING

2

18 3000132

NUT, CAGE, 8-32, ZP STEEL

2

19 0508910

HOUSING, 4 DIA x 20"L, SS 304, UF

1

20 2180560 CAP, NORYL, 3/4 PEX X 3/4 PEX, 4" DIA SS HSG 2

21 0200283

O-RING, 21MM ID X 4MM W, EPDM 70, RND

4

22 2180278

O-RING GUIDE, 3/4" CTS

4

23 2180279

COLLET, 3/4" CTS

4

24 8000057

BOLT, M8x1.25x35mm, HEX, 18-8 SS

4

25 8000059

WASHER, FLAT, M8, 8.4 ID x 16 OD x 1.6 D

4

26 8000058

NUT, M8 x 1.25 x 6.5mm, 18-8 SS

4

27 2120285

SPACER, 5/8 OD X 3/8 ID X 1/2 D

4

28 2170140

REGULATOR, FLOW 7.9 GPM

1

29 2110217

CLAMP, 304 SS, 4" SS UF HOUSING ENDCAP

4

30 3080120

SCREW, MACH. #8-32 x 5/8"

2

31 0200432

O-RING, AS568 2-342, EPDM 70

4

32 0200236

O-RING, CARTRIDGE

4

33 0700769

WIRE HARNESS, GAP-421 VALVE

1

34 2190210

FITTING, 3/4 MPT X 3/4 CTS STEM, JG

2

35 2170173

VALVE, BALL, 3/4 CTS X 3/4 FPT, BLACK, PLASTIC

1

36 2180575

BUSHING, PVC, .906 OD X .656 ID X .218 L

1

37 2140163 THREAD SEALING COMPOUND, (RECTORSEAL) 1

38 2140144

TAPE, PIPE THREAD

1

39 2140153

LUBRICANT, DOW CORNING, HIGH-VACUUM GREASE

1

40 4060173

CABLE TIE(.100x4-3/16)

1

41 1200168

ASSY/TEST PROCEDURE GAP

1

42 0200476

GASKET, VZN-5XX UF HSG, CLAMP BRACKET

2

43 2190304

COLLET CLIP, 3/4 CTS

4

D

C

B

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

E

F

E

F

A

ALL DIMENSIONS: INCH [mm]

TOLERANCES:

FRACTIONS

1/32" [.8mm]

DECIMAL

.xx

.01" [.25mm]

.xxx

.005" [.125mm]

ANGULAR:

1

MATERIAL SPECIFICATION:

DRAWN BY:

DATE:

PART DESCRIPTION:

SIZE:

C

PART NUMBER:

REV:

SHEET 1 OF 2

1:4

UNLESS OTHERWISE SPECIFIED:

8/1/2018

RDB

0013992

SEE BOM

MAIN ASSY, VZN 520H

D

THE INFORMATION AND DESIGNS CONTAINED IN THIS DRAWING ARE CONFIDENTIAL AND THE

PROPRIETARY PROPERTY OF A.J. ANTUNES & CO. NEITHER THIS DESIGN NOR ANY INFORMATION

CONTAINED HEREIN MAY BE REPRODUCED OR DISCLOSED TO OTHERS WITHOUT THE EXPRESS

WRITTEN CONSENT OF A.J. ANTUNES & CO.

SCALE:

DATE:

APVD BY:

INTERPRET DIMENSIONS AND

TOLERANCES PER ASME Y14.5-2009

NO BURRS ALLOWED

BREAK ALL SHARP CORNERS

THIRD ANGLE

PROJECTION

DO NOT

SCALE

DRAWING

180 KEHOE BLVD, CAROL STREAM, IL 60188

ISO COMPLIANT COMPANY

Back Plate

(holes along bottom for

additional mounting stability)

Back Plate

(holes along right

for additional

mounting stability)

Solenoid Valve

at Top

Mounting

Holes

Secure Mounting Bracket

to wall studs using

appropriate hardware.

The system is

designed to hang

from the Mounting

Bracket.

The system is

designed to hang

from the Mounting

Bracket.

Secure Mounting

Bracket to wall studs

using appropriate

hardware.

Caution

Due to its weight and size, the

VZN system MUST be mounted

with the provided Mounting

Bracket. Read the Mounting

the System section before

attempting to mount the VZN

system. Use care when lifting

heavy objects.

4. With assistance, lift the system and

seat it securely onto the Mounting

Bracket vertically (Figure 2A).

5. When mounted vertically, the back

plate has mounting holes across the

right portion to secure the right side

of the system to the wall.

Figure 2A. Vertical Mounting