4

The Power Extension Cables described here are intended for use in Explosive Atmospheres

in accordance within the limitation of the ratings. It is the user's responsibility to determine

the suitability of the equipment for the intended purpose.

ATEX / IECEx Power Extension Cables are designed to temporarily extend the reach between

an AC power source and an electrical device, such as portable fans, area lighting, etc., for

use in hazardous locations.

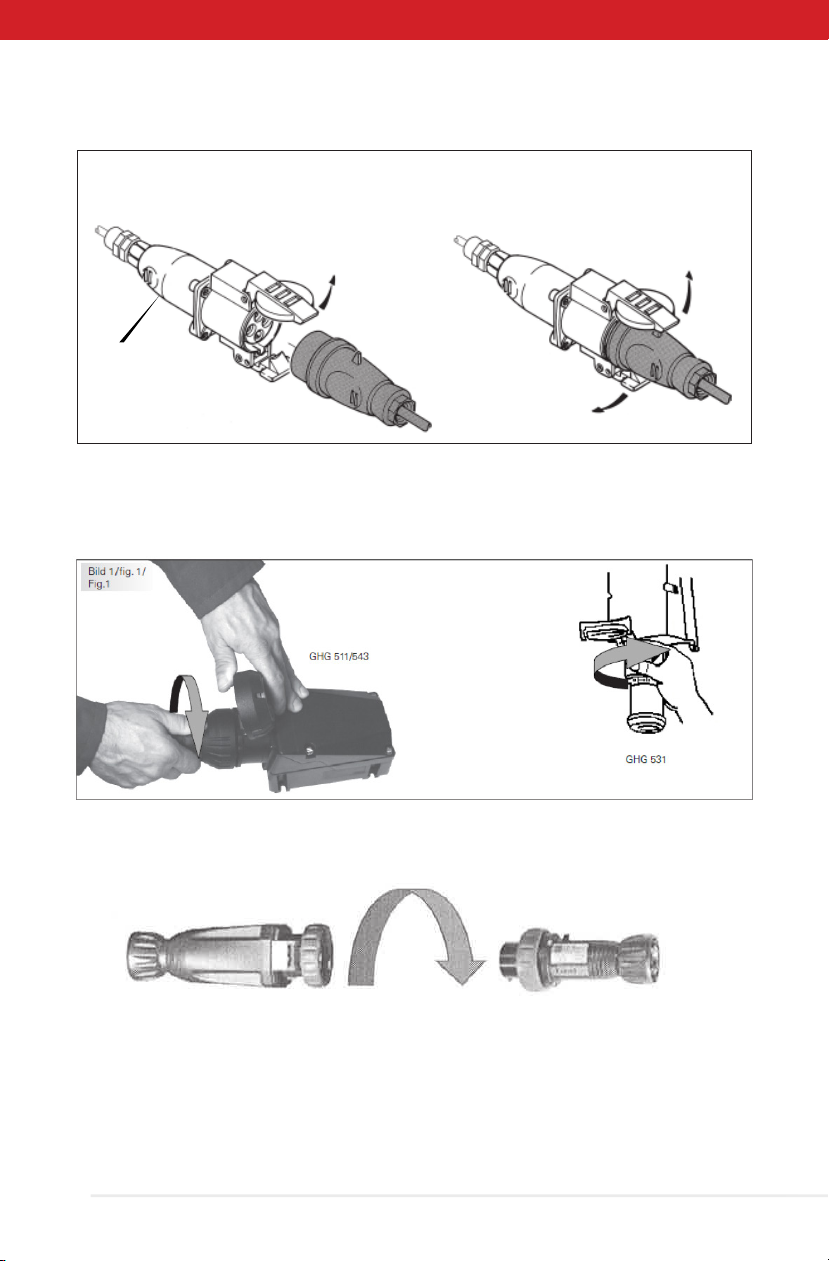

The power cables are built with three critical parts; Cable, Plug, and Couplers. Cables were

selected based on the need for extra heavy-duty applications. Plugs and couplers were

selected based on the most commonly used European connectors for hazardous locations.

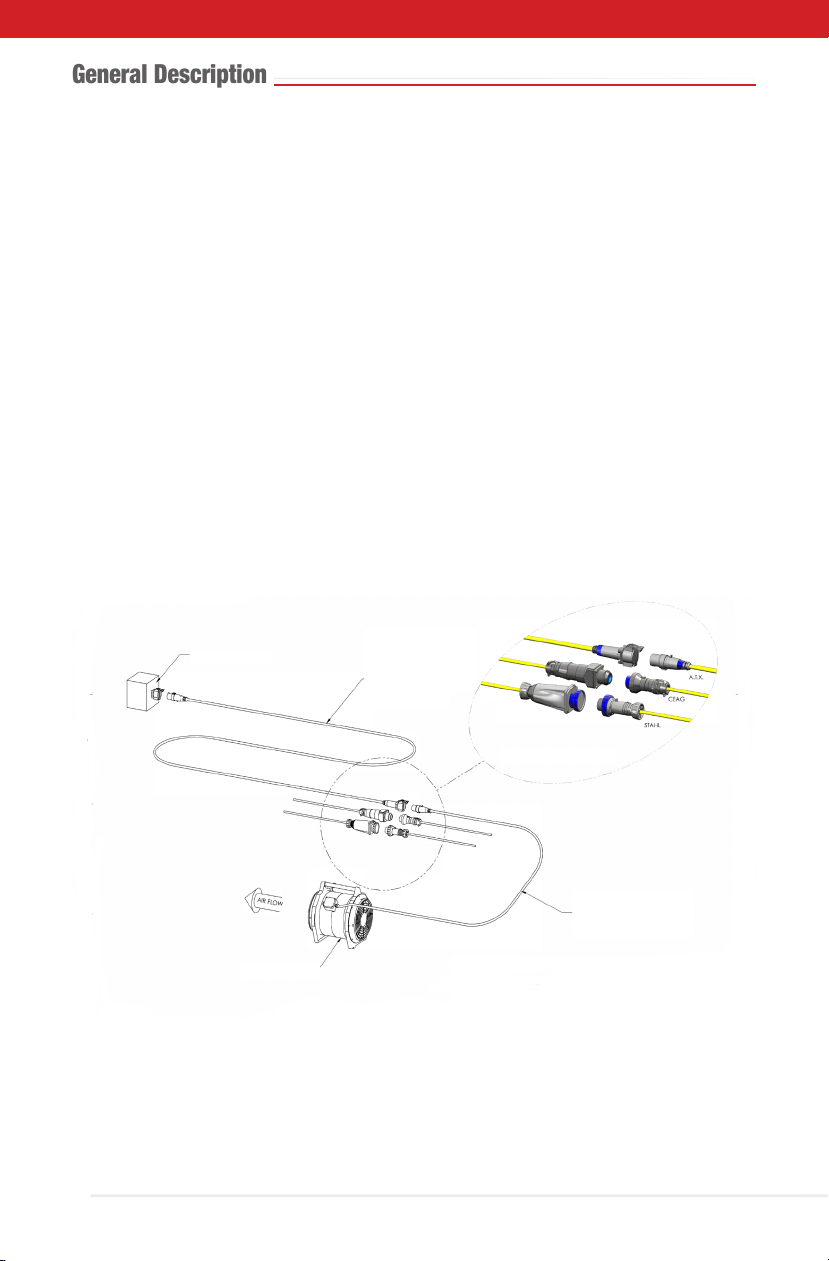

The drawing below depicts the ATEX / IECEx Power cable application, used to extend the

reach of a portable ATEX fan with H07RN-F cable and with three of the most popular brands

of A.T.X, CEAG, and R. Stahl, connectors.

The ATEX/IECEx Power Extension Cables are available for 110VAC or 240VAC power

requirements.

The Power Extension Cables have been certied to meet the ATEX Directive 2014/34/EU

certication for Ex de G D Ex de IIB, Zone 1, 2, 21, & 22.

25 POWER CORD,

H07RN-F FACTORY

INSTALLED

ATEX PLUG & COUPLER

PORTABLE FAN

POWER SOURCE

ATEX EXTENSION

POWER CORD.

3C, 1.5mm2, H07RN-F,

3C, 2.5mm2,H07RN-F,

OR 3C, 4mm2,H07RN-F