Loco-1 / Loco-2

V1.1 - English page 9 of 36

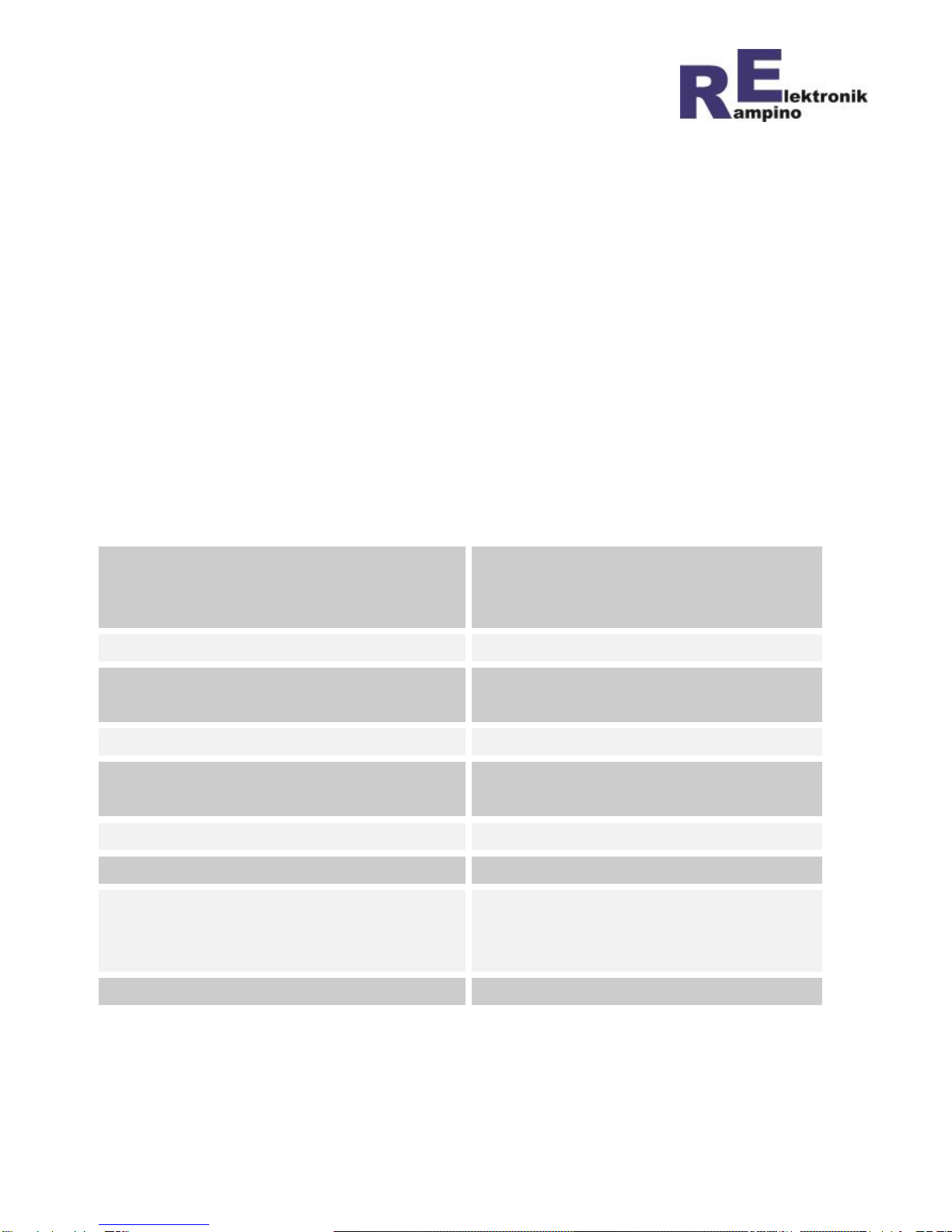

Connection of LEDs as a consumer

The function outputs (AUX1 to AUX 4) are switched towards the

decoder ground. Therefore the cathode (-) of the LEDs have to be

connected to the output of the function outputs (AUX).

The anodes of the LEDs, have to be connected to the decoder

connection with the designation ‘+'.

Attention:

If you are using LEDs, you must always operate them via a series re-

sistor. The series resistors are different depending on the rail power

and the characteristics of the LEDs. Determine the correct value for

the corresponding LED. You can connect several LEDs in parallel to

each output. In this case, each LED must have its own resistor. If you

connect several LEDs to one output in series, only one series resistor

is needed.

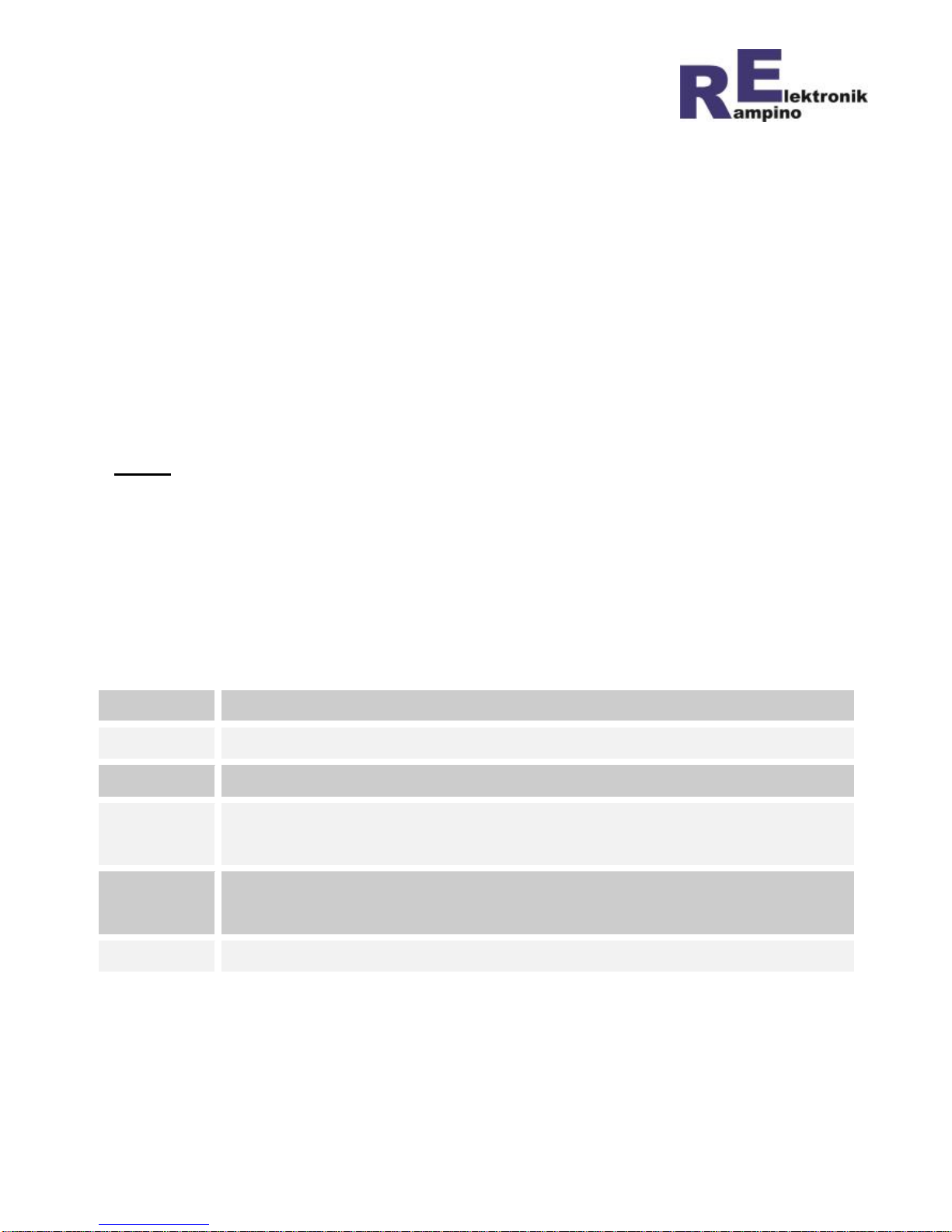

Connecting a backup capacitor

In track sections with bad contact the power supply of the decoder

can be interrupted briefly. At solder pads ‘C –‘ and ‘C +’a backup

capacitor (e.g. electrolytic capacitor 100 µF / 35V) can be soldered, in

order to improve power supply. Pay attention to the polarity of the

capacitor! The positive pole is connected to ‘C +’, the negative pole to

‘C –‘.

Note: When using the decoder in analogue AC operation, the use of

a backup capacitor is recommended in any case.

Mounting/fastening the locomotive decoder

After completing of all connections to the decoder it should be

fastened. This can be done e.g. with double-sided tape. Please note

that the decoder heats up and the applied adhesive tape can possibly

be solved by heating. Take care that the decoder has no contact with

the conductive enclosure or chassis parts of the locomotive when

mounting.