2

WARNING: READ ALL INSTRUCTIONS THOROUGHLY FROM

START TO FINISH BEFORE BEGINNING INSTALLATION. Failure to

follow the warnings and instructions provided herein can result in an

accident, severe personal injury or death.

PRELIMINARY

This manual presumes that all persons installing this suspension

s stem have a high level of mechanical training and experience, and

have available to them all necessar tools and safet equipment. This

manual is not and should not be construed as an exhaustive list of all

required safet measures. Personnel should rel primaril on their

training and experience, as well as on their own common sense.

This Manual is to be read as a supplement to, and must not be

construed as a substitute for, the owner’s manual and/or shop

manual that originall accompanied the vehicle. Refer to such use,

operation, maintenance and safet manuals as necessar , and

especiall after installation is complete, to insure proper vehicle

operation.

The following terminolog has been used in this Manual:

ACCIDENT: An event which could cause personal injur or death to

an one installing or using the suspension s stem, as well

as to passengers and b standers, or otherwise ma result

in propert damage.

PRE-INSTALLATION WARNINGS and INSTRUCTIONS

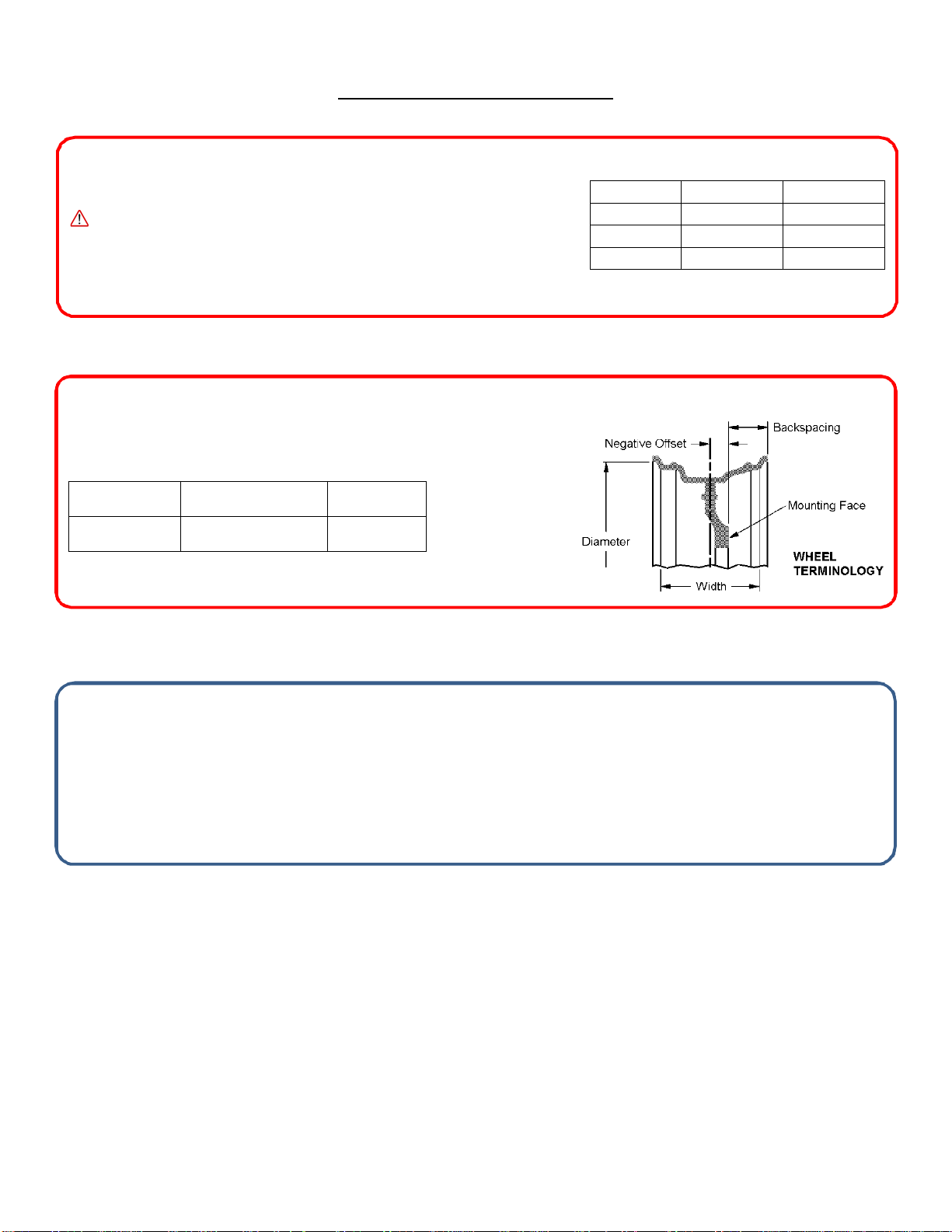

WARNING: Only the following rim/tire sizes may be used with this

suspension system: 295/60R20 tire, 20x9-in 0 offset wheel.

Use of any other rim/tire combination increases the risk of a roll-over

and/or accident, resulting in severe personal injury or death.

WARNING: This suspension system will enhance the off-road

performance of your vehicle. It will handle differently; both on and off-

road, from a factory equipped passenger car or truck. Failure to drive

this vehicle safely may result in serious injury or death to the driver and

passengers. ALWAYS WEAR your seat belts, REDUCE your speed, and

AVOID sharp turns and other abrupt maneuvers

1)

Service and repair tasks require specialized knowledge, training,

tools, and experience. General mechanical aptitude ma not be

sufficient to properl install this suspension s stem. If ou have an

doubt whatsoever regarding our abilit to properl install the

suspension s stem, please consult a qualified mechanic.

2)

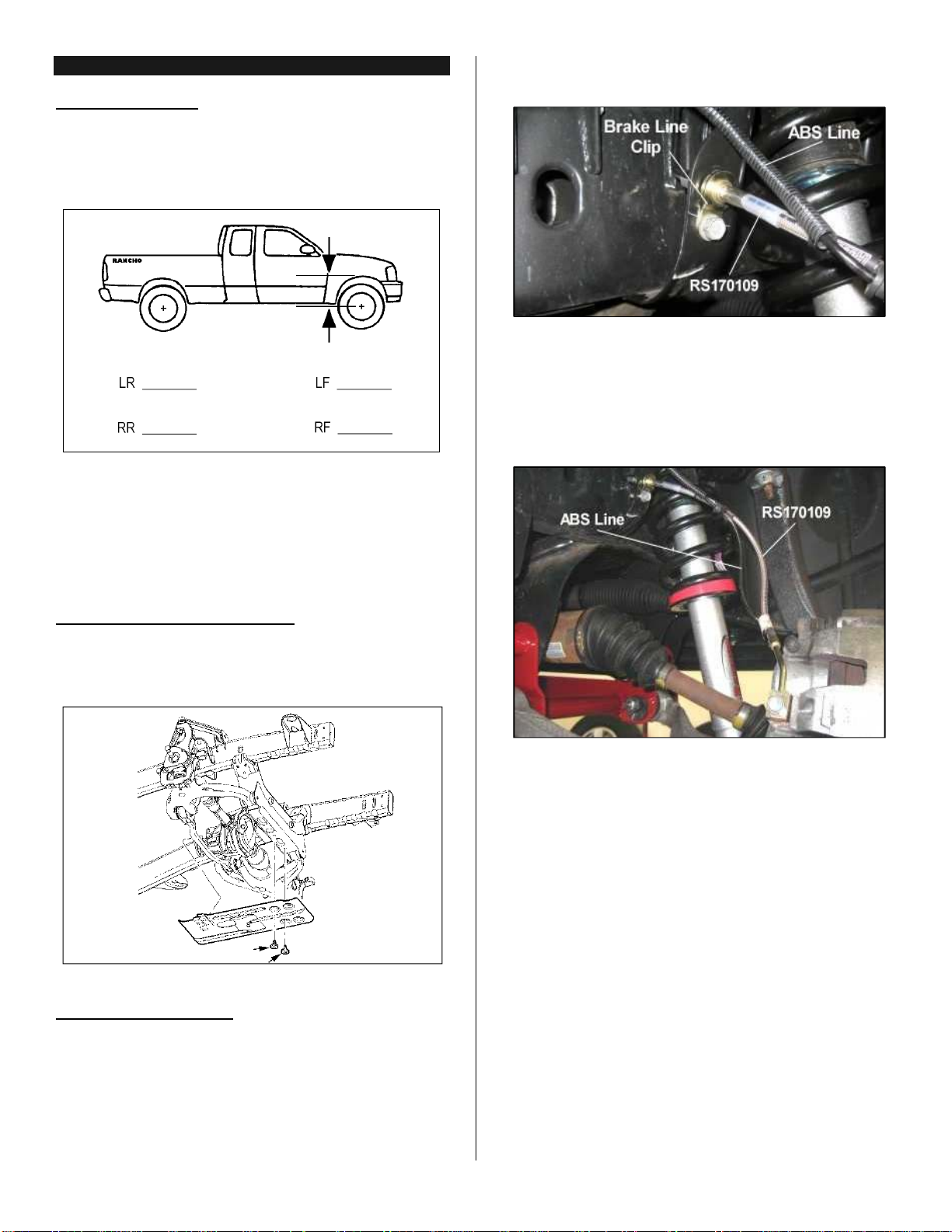

Your brake lines and fuel lines should remain undisturbed during

and after installation. If ou think ou need to modif these

components in an wa , ou are mistaken. You are installing the lift

improperl and will be creating a significant risk of an accident. In case

of an doubt, consult a qualified mechanic.

3)

If an component does not fit properl , something is wrong. You

are installing the lift kit improperl and will be creating a significant

risk of an accident. Never modif an component of the vehicle or

suspension s stem, except as instructed herein. Do not continue with

installation until ou have identified the problem.

4)

Several of the procedures described herein require at least two (2)

persons to safel complete the task. If ou have an doubt about our

abilit to complete an operation b ourself, alwa s ask for help

from a qualified assistant.

5)

Before starting an operation, confirm that all personal safet

devices and safet equipment are in proper condition and position.

6)

Give our work undivided attention. Looking around, carr ing on a

conversation and "horse-pla " are careless acts that can result in an

error in installation and/or serious injur .

7)

Install onl tires approved b the United States Department of

Transportation (“DOT approved”). Make sure the rim and tire size are

properl matched.

8)

If an components of the vehicle or suspension s stem are

damaged in an wa during installation, immediatel replace the

component.

9)

During installation, carefull inspect all parts of the vehicle and

replace an thing that is worn or damaged.

10)

Nip points present the risk of the catching, lacerating, crushing

and/or amputating fingers, hands, limbs and other bod parts during

operations. Alwa s keep clear. Wear protective gloves.

11)

Oil and h draulic fluids are poisonous, dangerous to health and

are known to the State of California to cause cancer, birth defects or

other reproductive harm. Do not inhale vapors or swallow. Do not

allow contact with the e es or skin. Should an oil or fluids be

swallowed or inhaled or come into contact with the e es,

immediatel follow the safet precautions on the label or call a poison

control center immediatel . Should an of the oil or fluids contact

our skin, immediatel wash thoroughl .

12)

Never install the suspension s stem if ou are under the effects of

alcohol, medications and/or drugs. If ou are taking prescription or

over the counter medication, ou must consult a medical professional

regarding an side effects of the medication that could hinder our

abilit to work safel .

AFTER INSTALLATION WARNINGS AND INSTRUCTIONS

13)

After installation is complete, drive the vehicle slowl in an area

free from heav traffic for at least three (3) miles. Likewise, before

traveling on an highwa s or at a high rate of speed, drive the vehicle

for ten (10) miles on side roads at moderate speed. If ou hear an

strange noise or feel unusual vibration, if a component of the

suspension s stem is not operating properl , or if an warning lights

illuminate or buzzers sound, stop the vehicle immediatel . Identif

the cause and take an necessar remedial action.

14)

Confirm that all components of the vehicle, including all lights

(headlights, turn signals, brake lights, etc.), linkages (accelerator,

etc.), electrical switches and controls (windshield wipers and

defoggers, etc.), and other warning devices (low tire pressure

monitoring s stems) are full operational.

15)

Your headlights will need to be readjusted before the vehicle is

used on the roads. Consult the vehicle owners’ manual.

16)

The speedometer and odometer will need to be recalibrated after

installation. See our dealer.

17)

Confirm proper rear view and side view while seated in the driver

seat. Install supplemental mirrors as necessar .

18)

Your original low tire pressure monitoring s stem ma be re-

installed in our new wheels. However, if ou choose to purchase a

new s stem, see our dealer to have them properl calibrated. Proper

tire pressure is critical to safe operation of the vehicle.

OPERATION

19)

Because it has been modified, the vehicle will not handle, turn,

accelerate or stop in the same manner as an unmodified vehicle. In

addition, the crash protection s stems designed in the vehicle ma

operate differentl from an unmodified vehicle. For example, turning

and evasive maneuvers must be executed at a slower rate of speed.

Further, there is a greater risk that the vehicle could roll over. These

differences could result in an increased possibilit of an accident,

personal injur or death. Learn the vehicle’s operations and handling

characterizes and drive accordantl .