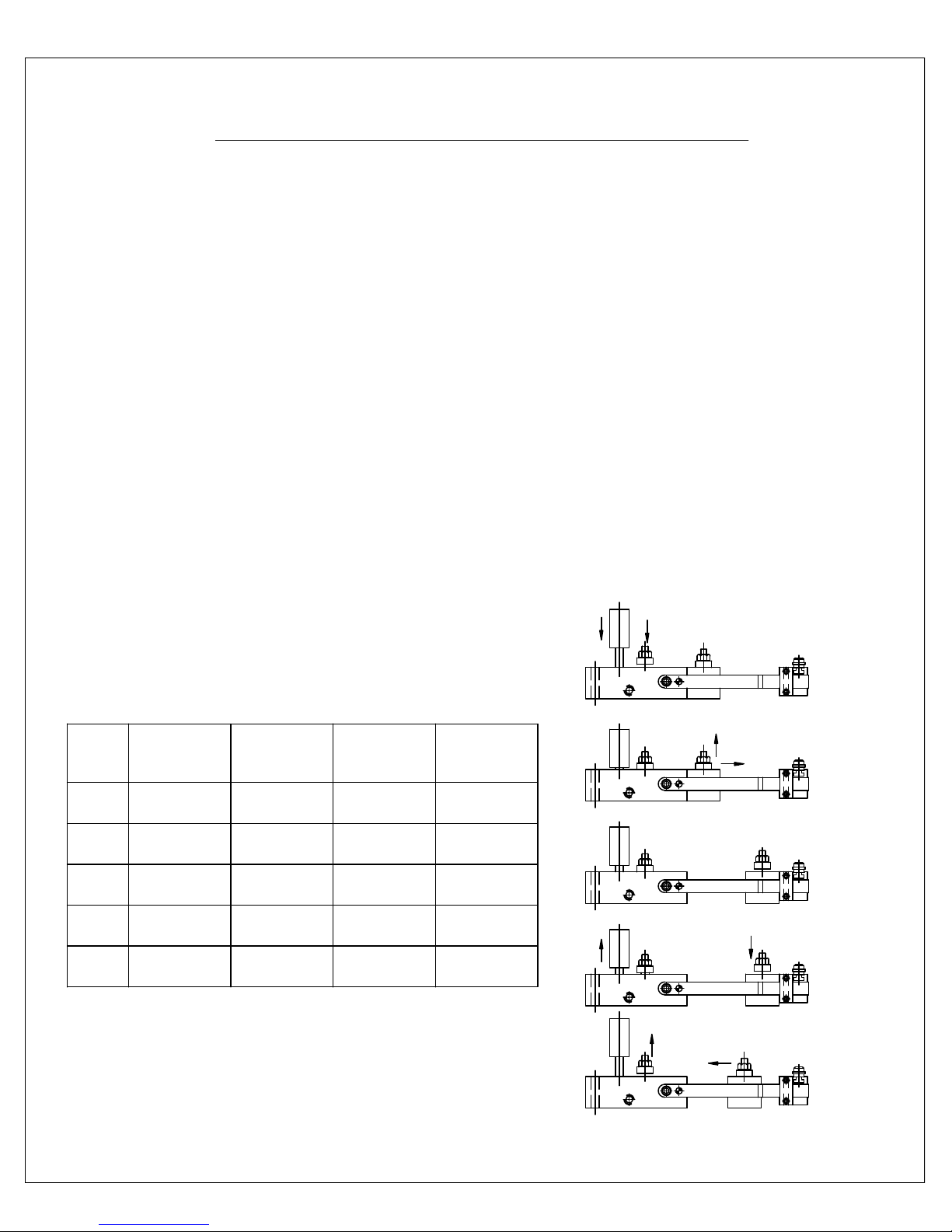

INSTALLATION & OPERATING INSTRUCTIONS

Stock Guide Rollers: The stock guide rollers are adjusted by loosening

the screws and moving the rollers along the slot to the

desired position, then re-tightening the screws. For best

results the stock should be centrally located in the feed.

Clamp Washers: Rapid-Air feeds are shipped with the clamp washers

on the top side of the clamps. These washers can be changed

from the top side of the clamps to the under side of the clamps

to accommdate thicker materials. Do not operate the feed

with loose feed and stock clamps.

Feed Length Adjustment: The notches in the guide rail provide for

coarse adjustment. Remove stop block clamps and move

stop block to desired location, then re-install clamps. The

final (fine adjustment) is made by the adj. screw in the stop

block. After final adjustment has been made, secure adj.

screw with locking nut located at the rear of the stop block.

SETUP: With air off, insert stock between the stock guide rollers and

then pass the stock under the feed clamp. Lift the stock clamp

and push the stock through to the starting position. Turn air

on, install safety guards, your feed is now ready for operation.

SPEED ADJUSTMENT: The speed adjusting screw on all Rapid-Air feeds

adjusts the forward speed of the slide block when feeding stock

into a die. High accuracy under special conditions can thus be

maintained by eliminating inertial slippage caused by oily or

heavy stock. The speed adjusting screw is located on the top

of the main body, opposite the actuating valve. Adjust for slower

speeds by turning the screw clockwise. Rapid-Air feeds are

shipped with the speed adjusting screw set to provide the best

operating conditions for the majority of applications.

4