3

OPERATION

Use ONLY PURASAN®Tablets.

DO NOT add any other chemicals or cleaning products to the

toilet or the treatment system. Raritan C.P. (part # 1PCP22) -

Cleans Potties is the only factory-recognized cleaning product

that may be used in the toilet.

REFILLING TABLET CARTRIDGE

(#41-135A)

When Error LED is ashing it is an indication tablets in the

dispenser are depleted to less than one tablet and rell is

needed.

Press No discharge button to stop cycling.

1 Remove all water by pressing “empty” button on the

panel before opening lid.

2. Turn o power.

3. With adequate ventilation available, unscrew tablet

dispenser lid.

4. Reload with two tablets into the cartridge.

5. Replace lid on Tablet Dispenser.

6. Turn on power

7. Press NO DISCHARGE mode button to return to

treatment mode

CLEANING: Do not add any other chemicals or cleaning

products to the toilet or the treatment system.

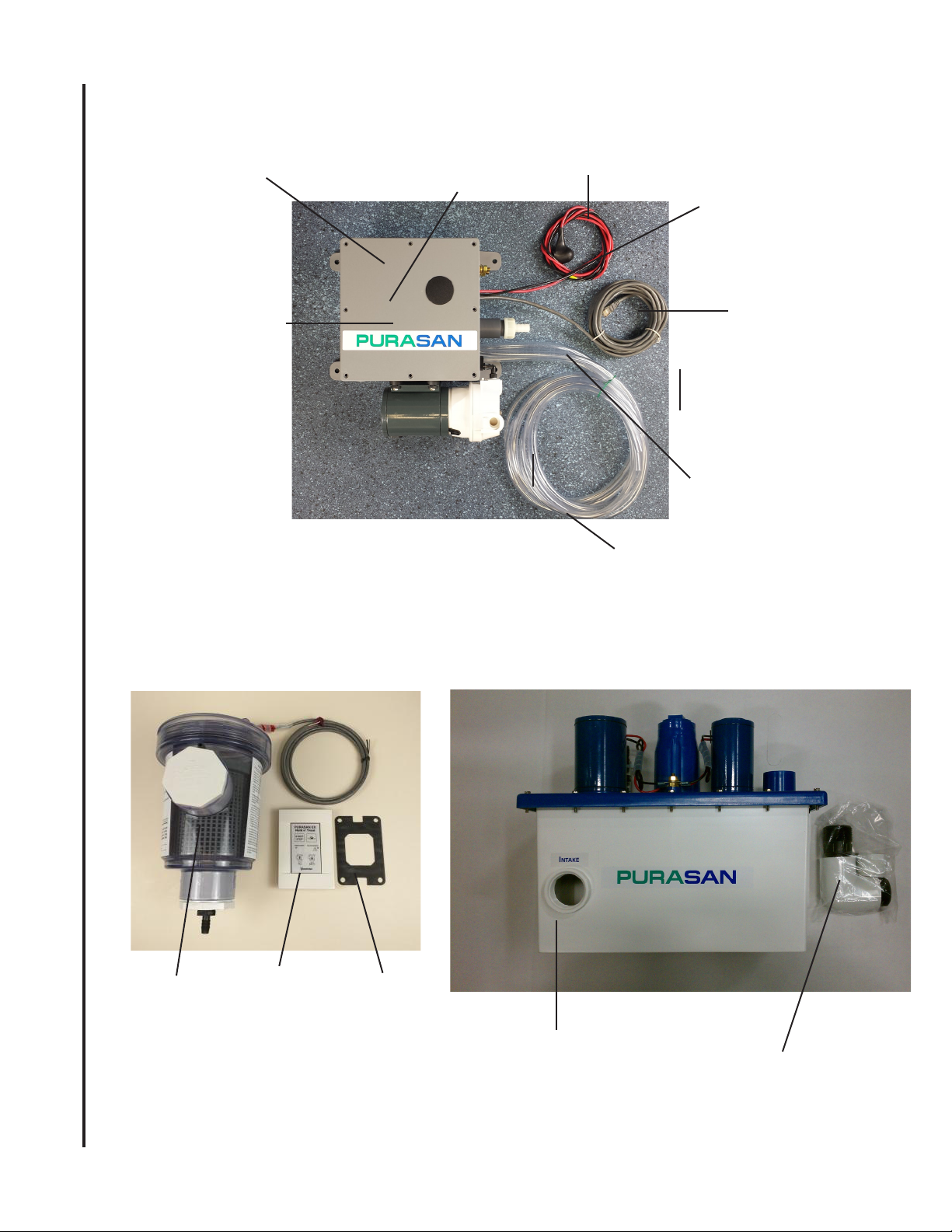

REFILLING TABLETS

FIG 4

Insert Tablet

2 Tablets Only

OPERATION NOTES:

1. If start/stop button is pressed during rst 20 seconds of

treatment cycle, motor will stop, A drain cycle will start to

empty out and water in the dispenser before stopping the

cycle. If waste level is higher than the low level sensor , next

cycle will start immediately.

2. A cycle can be terminated by pressing NO discharge mode

button. A drain cycle will run to empty out water in the tablet

before terminating cycle. Cycle will not restart until mode

is changed to treatment mode and Level is higher than low

level.

3. If cycle completes normal, there is a 8 second pause before

next cycle will start. During this pause none of the buttons

except No Discharge mode button is functional.

MAINTENANCE

CAUTION: Do not load tablets into Tablet Dispenser until

Steps 1-6 are completed.

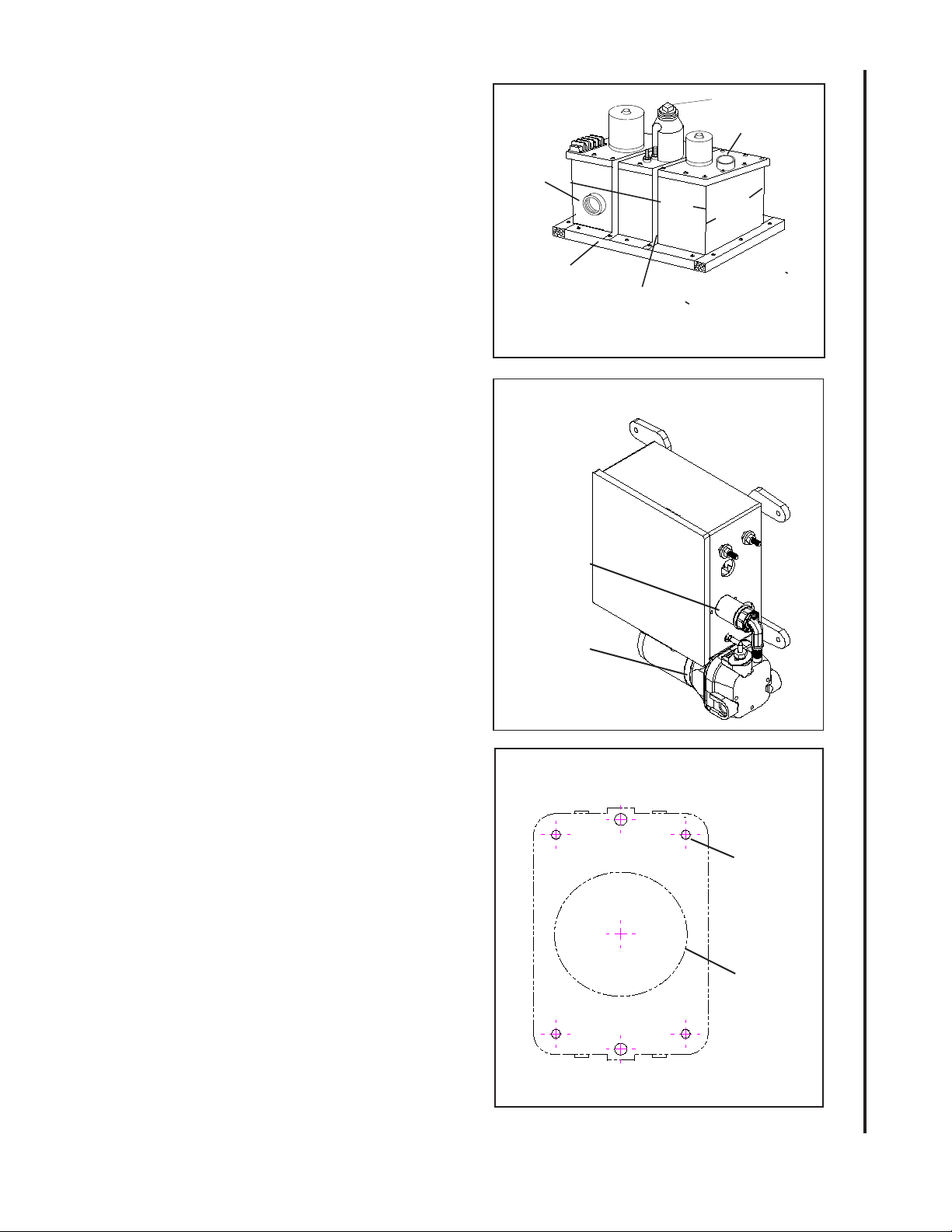

1. Remove crossover cap (see FIG 12; #25) from Treatment

Unit tower. Pour 3 gallons (11.5 liters) of water into treat-

ment unit. Replace crossover cap.

2. Turn on water to the Water Valve.

3. Turn on power to unit.

4. Priming: Press and hold “FILL” button until water reaches

to the water line on the Tablet Dispenser. Press and hold

“EMPTY” button until Tablet Dispenser and 3/8” tube

to Treatment Unit is empty.

5. Operate the system. Check water level in the cartridge and

make sure water is rising to the mark. If starting for rst

time or if water does not rise to the mark, see instruction

in Programming section to adjust timing.

6. Check for leaks.

7. Load the Tablet ( see relling tablet section).

INITIAL START-UP - AFTER ALL INSTALLATION STEPS ARE COMPLETE

CLEANING OF TANK CHECK VALVE(41-156)

AND ½” HOSE

A. Every 50 cycles, clean ½” hose and check valve

(41-156) on tank using following procedure:

1. Press ll button till water lls up entire ½”

hose just below tablet dispenser

2. Press and hold “empty” button until all hoses up to

check valve on treatment tank are empty.

3. Repeat steps 1&2 three more times.

B. Every time tablets are relled, check valve assembly on

the treatment tank must be cleaned.

1. Close seacocks

2. Close hose clamp completely. Remove check valve

assembly and thoroughly clean assembly with warm

water. Make sure check valve plunger is moving by

actuating with a paper clip. If check valve is stuck, replace.