INASI

"V TECHNICAL DATA

1. TECHNICAL DATA

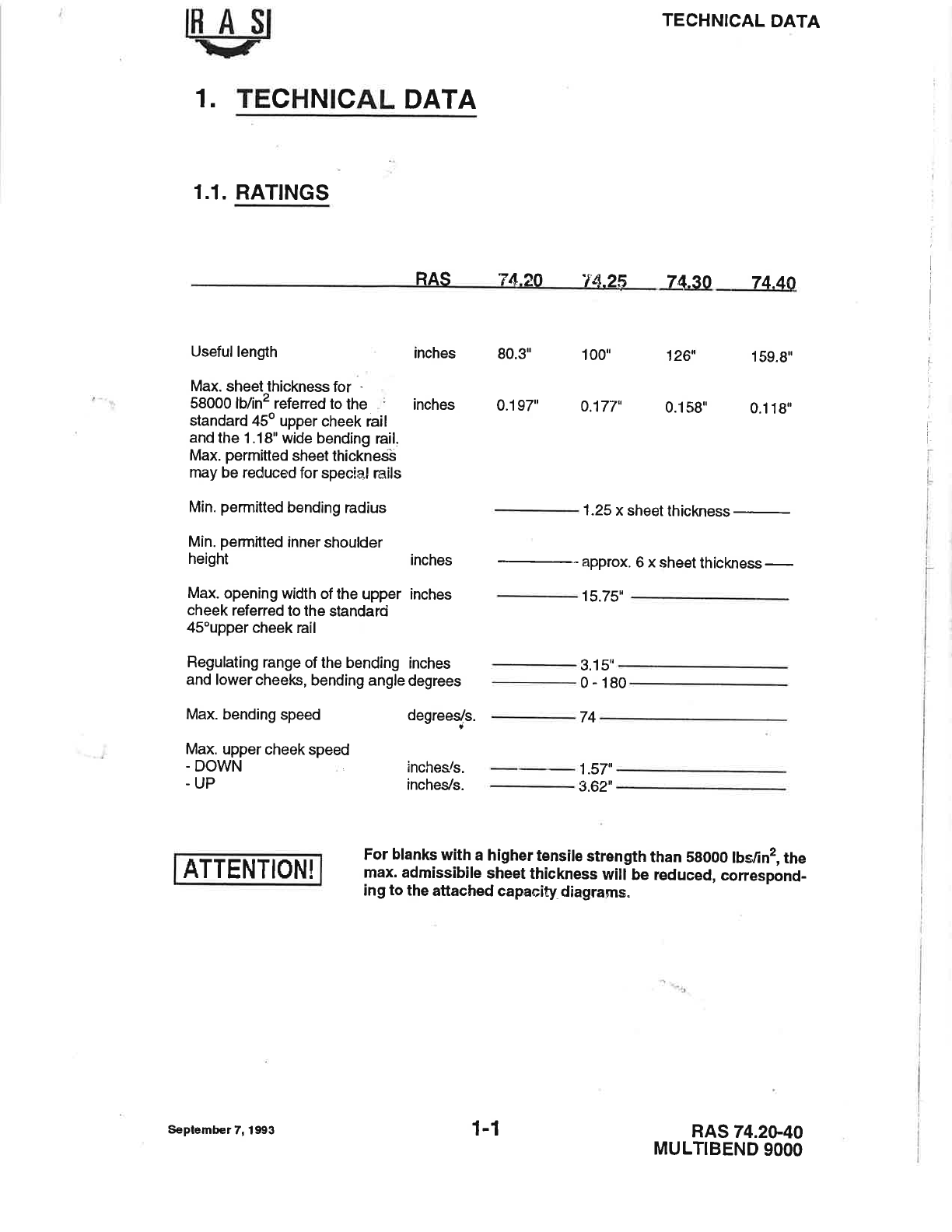

1.1. RATINGS

RAS v4_20 "f4.25 7t1.30 74.40

i

I

I

I

I

l

:

l

1

i

I

Usefullength

Max. sheet thickness for -

58000 lb/in2 refened to the inches

standard 45o upper cheek rail

and the 1.18" wide bending rail.

Max. permitted sheet thicknesb

may be reduced for special rails

Min. permitted bending radius

Min. permitled inner shoulder

height

Max. opening width of the upper inches

cheek referred to the standard

45"upper cheek rail

Regulating range of the bending inches

and lower cheeks, bending angle degrees

Max. bending speed degrees/s.

Max. uppercheekspeed

- DOWN

.UP

ATTENTION!

inches 80.3" 1 00" 126" 159.9"

0.197" 0.177. 0.159" 0.1 19"

1.25 x sheet thickn

inches approx. 6 x sheet thiskngss -

inches/s.

inches/s.

15.75"

3.1str _

0-180

74_

1.57il _

3.62il _

For blanks with a higher tensile strength than 59000 lbsfin2, the

max. admissibile sheet thickness will be reduced, correspond-

ing to the attached capacity diagranns.

RAS 74.2G40

MULTIBEND 9OOO

September 7, 19!13 1-l