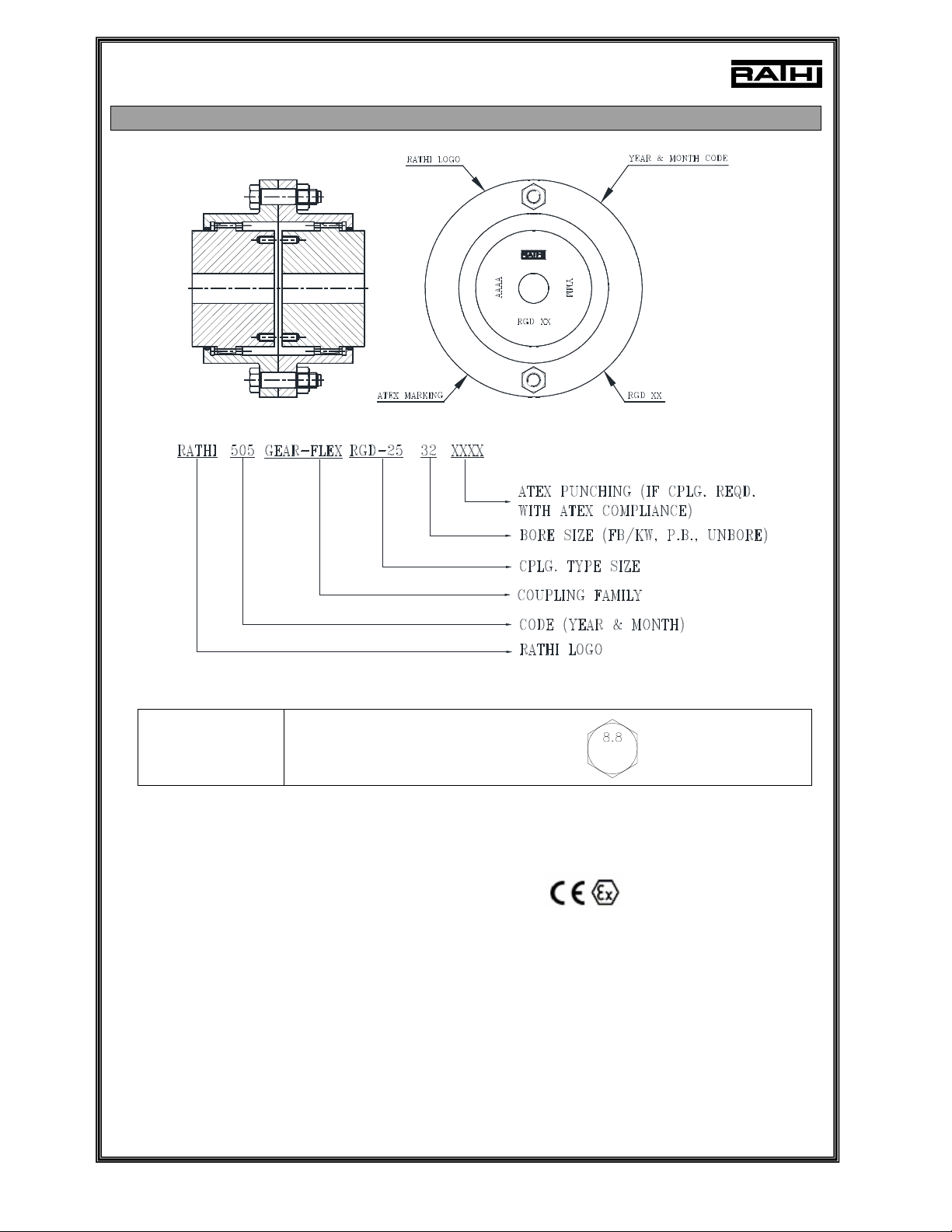

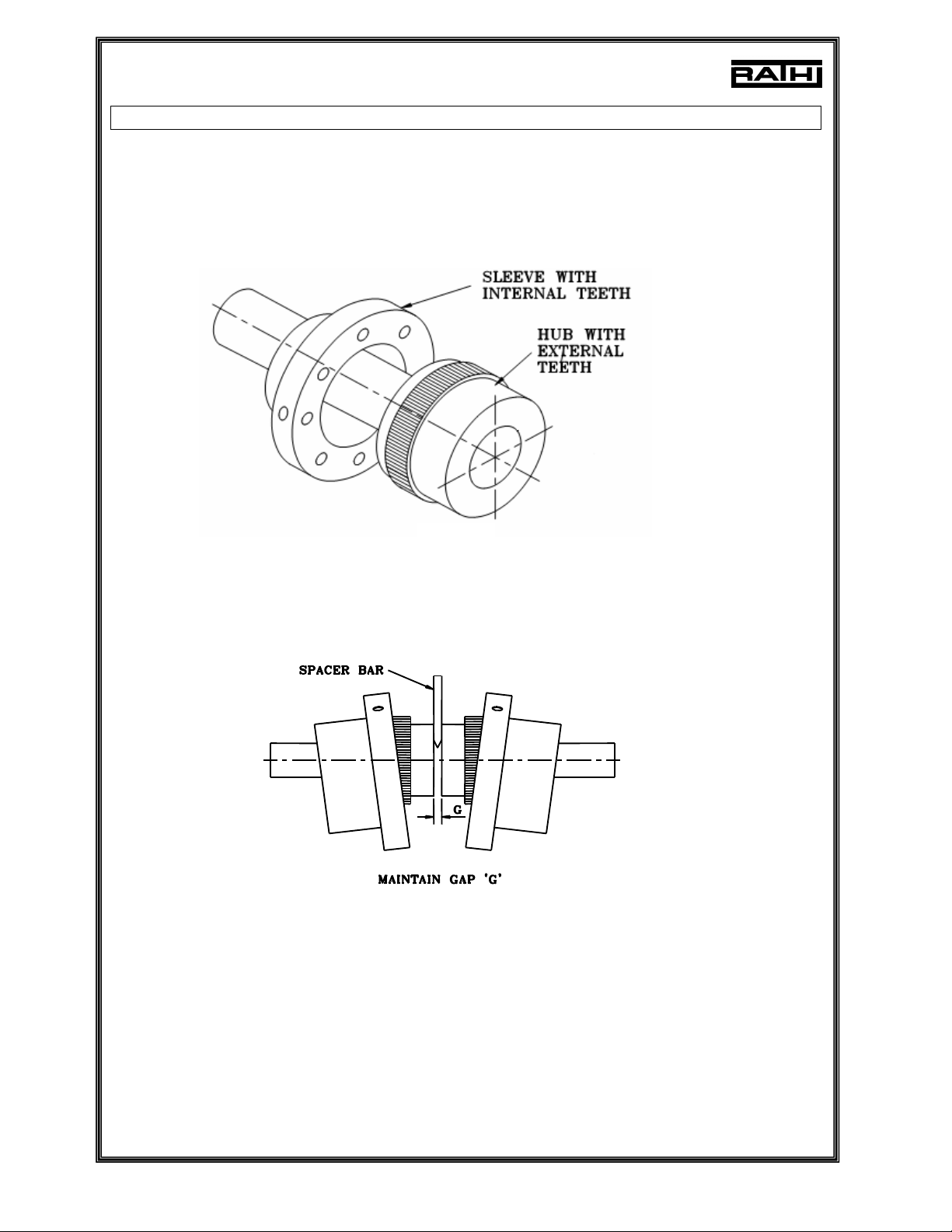

GEAR-FLEX COUPLING

RE-OM-G-04/00-05/15 Page 5

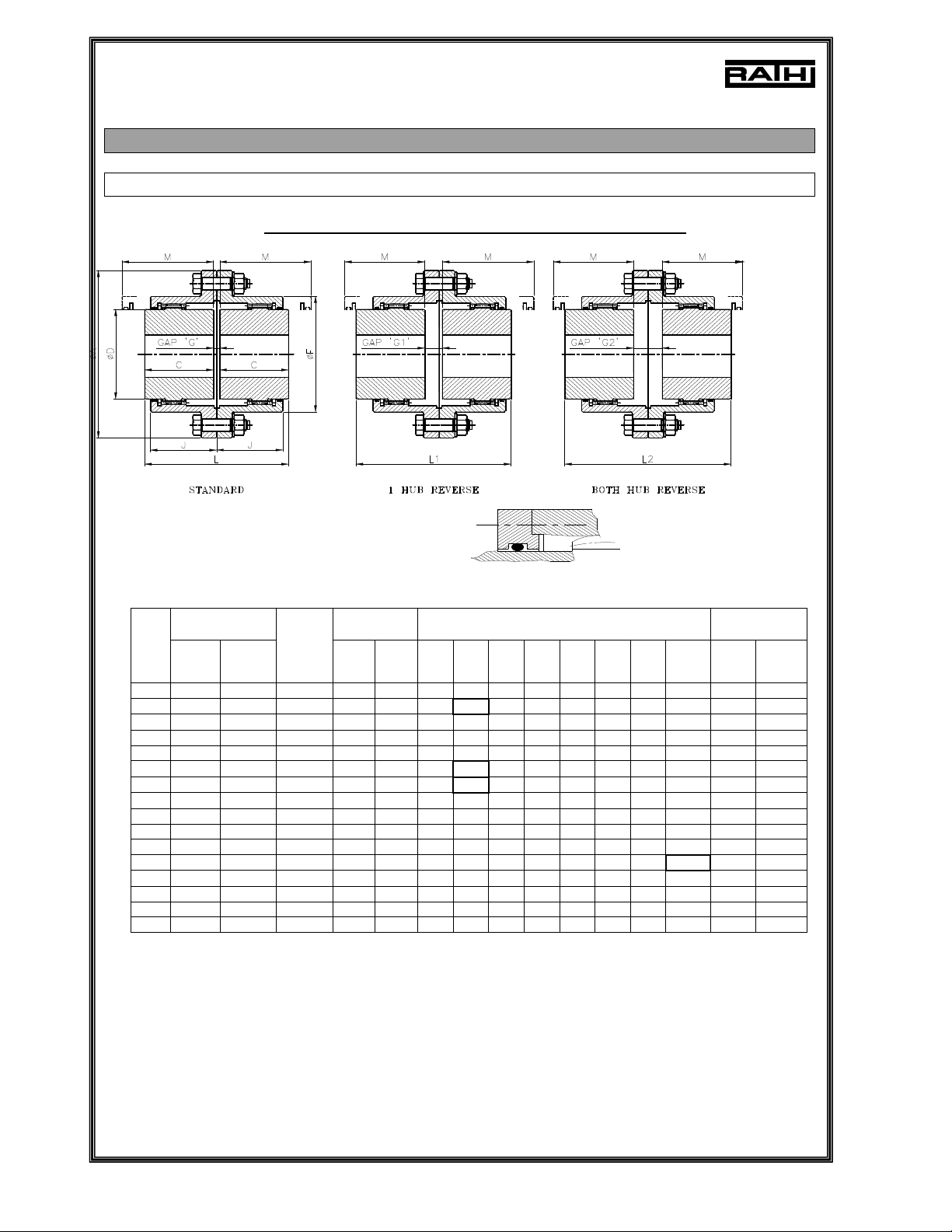

2. TECHNICAL DATA

2.1 DIMENSIONS, SPEED & WEIGHTS

Double Engagement Couplings: TYPE-RGD

THIS END COVER PLATE CONSTRUCTION FOR SIZE RGD-80 ONWARDS.

Coupling

Rating

Bore Dia

mm Dimensions in mm Solid Hub

Siz

e kW at

100

RPM

Rated

Torque

Nm

Max.

Speed

RPM Min.

Bore

Max.

Bore ØA L C ØD ØF J M GAP Mas

s Kg

WR²

Inertia

Kg m²

10 14 1337 8000 14 52 116 89 43 69 84 39 51 3 4.4 0.0052

15 30 2865 6500 22 65 152 103 50 86 105 48 61 3 9 0.0192

20 53 5061 5600 27 80 178 127 62 105 127 60 76 3 15 0.041

25 105 10027 5000 32 98 213 159 77 131 155 72 92 5 27 0.105

30 168 16043 4400 42 115 240 187 91 152 181 84 106 5 40 0.195

35 231 22059 3900 47 135 279 220 107 178 211 98 130 6 65 0.454

40 336 32086 3600 47 160 318 248 121 210 250 111 145 6 96 0.86

45 472 45073 3200 52 180 346 278 135 235 274 123 165 8 131 1.39

50 650 62070 2900 72 195 389 314 153 254 306 141 183 8 186 2.53

55 880 84034 2650 72 215 425 344 168 279 334 158 203 8 247 3.83

60 1205 115069 2450 77 235 457 384 188 305 366 169 228 8 299 5.21

70 1823 174084 2150 92 280 527 451 221 356 425 196 266 9 473 11

80 2639 252006 1750 95 285 590 508 249 385 485 243 300 10 682 20.72

90 3037 290012 1550 100 300 660 565 276 420 535 265 325 13 898 34.95

100 4100 391521 1450 120 330 711 623 305 470 595 294 355 13 1242 55.95

110 5300 506.1 1330 130 370 775 683 335 521 653 322 386 13 1608 86.14

NOTES:-

1. All dimensions in mm.

2. The outer dimensions of flanges are rounded up to nearest figure in above table.

3. For special versions contact M/s RATHI.

4. Couplings generally used up to 120°C. Can be used for higher temperatures by using proper grade of grease.

5. Weight & M.I. specified are with solid hubs.

6. Max. bore with key way as per DIN 6885/1.

7. ‘M’ minimum clearance required for aligning.