SWL25 Room-Selector

Installation

KI-1200A

Panels

Rauland-Borg Corporation

l

3450 West Oakton Street, Skokie, Illinois 60076-2951

l

(847) 679-0900

GeneralInformation

The SW25 offers room selection only (no call-in signal).

Description

The SWL25 also provides a call-in signal. When a call

The SW25 and SWL25 panels are

used

with all Director@ is made from a switch in the classroom, an LED lights next

Series sound and communications systems. These panels to the corresponding number on the panel and a tone alerts

let you selectively connect up to 25 rooms to either the the console operator to the call. The LED lamp remains lit

program or the intercom channel. There is also a center until the operator answers the call, at which time the lamp

OFF

position. Color-coded directions identify each chan- automatically shuts off.

nel: green for program, and orange for intercom.

Installation

Cabling Requirements

i../

Systems using the SW25 (no call-in signal) require one

twisted pair in a shield for each speaker station. Systems

using the SWL25 (call-in signal) require one additional

conductor within the shielded cable for each speaker

station. Use #22-AWG solid or stranded conductors with

22-AWG drain wire. If you’re

using

insulation-piercing

connectors, the outside diameter of any wire, including its

insulation, must not exceed

0.095”.

Cable Routing and Strain Relief

Route the cables as shown in the diagram. Secure them

with three plastic cable ties through the guide loops in the

rear bracket. Leave service loops in the cables

used to

interconnect the equipment panels and at least a one-inch

slack in each cable. This permits reconnection when

required.

Connect the twisted pair to terminals D and

E,

and the

drain wire to terminal G for each line circuit. On Model

SWL25 only, connect the third conductor for calf-in to

terminal T(Trigger).

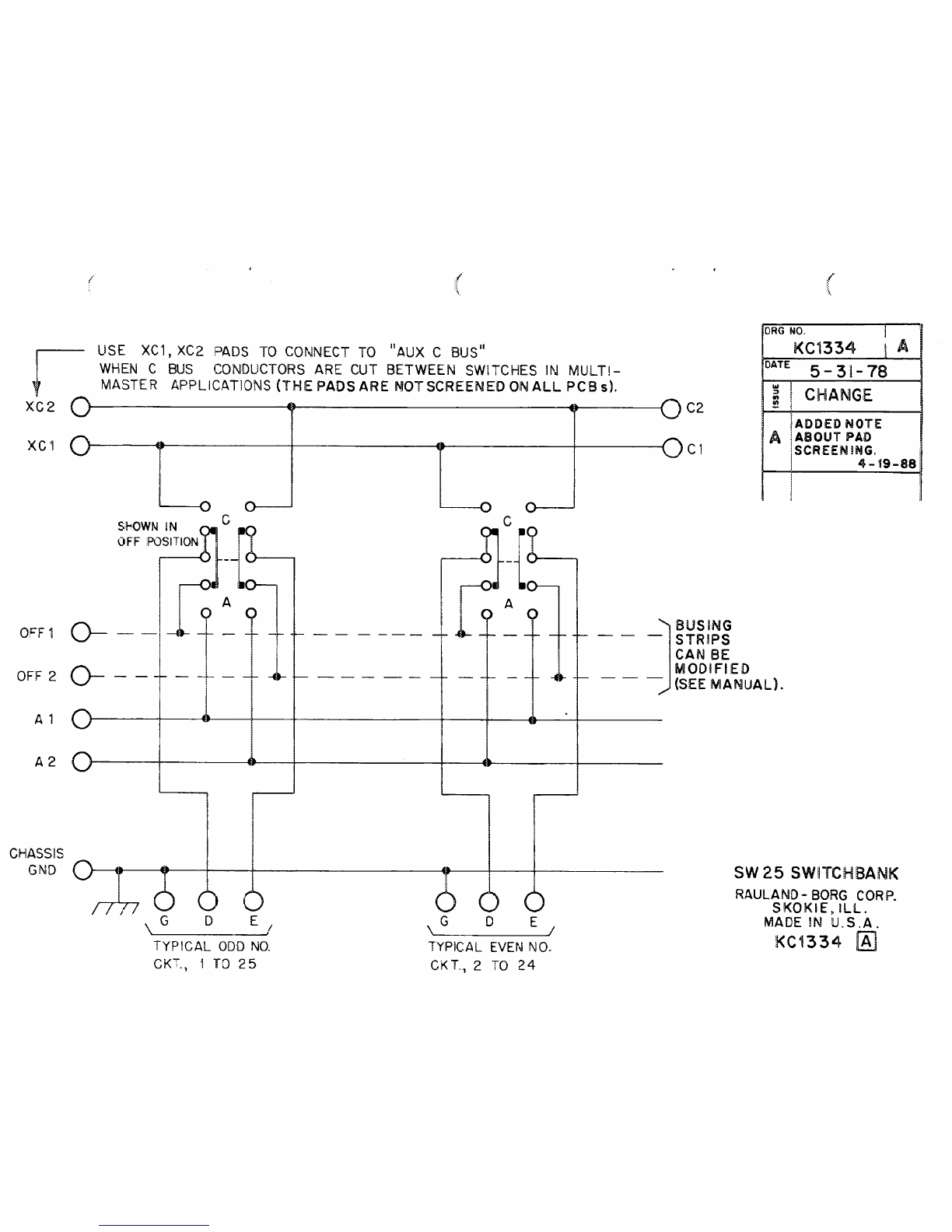

Connector or Bus Wiring

L,......./.

There are three terminals

(OFF, A, 0

at the ends of the

switchbank that will be interconnected in a factory-wired

system. These interconnections provide loop-through for

common functions, especially between multiple switch-

banks.

For wiring details, read the instruction manual for

the proper program and intercom equipment panel. When

you’re wiring to these end terminals, you may need to

cut

slots in the connector shells for loop-throughs between

switchbanks.

Recommended Terminations

Insulation-piercing connectors are the fastest, most re-

liable way to terminate wire to the switchbank. These

connectors must be ordered separately. Order one SK-2522

Connector Kit for each switchbank. The kit contains 25

four-terminal connectors for 22-AWG wire. The attached

manual, KI-1564, tells how to install these connectors.

Alternative Method #I

Modified wire wrapping may be used to terminate 22-

or 24-AWG solid conductors. Strip back wire about lb” and

use a wire-wrapping tool that provides one complete turn

of insulation around the terminal pin. This modified wire

wrap provides the required strain relief.

Alternative Method #2

Crimped connectors may be used where there is a

mixture of wire gauges (18-24 AWG) in the system, or

where preferred. Multiple-gauge crimped connectors and

an adapter shell are required for this termination method.

Order one CTA25 Terminal Adapter Kit for each switch-

bank in the system. The kit contains 25 four-terminal

adapter housings and 100 crimp connectors. Hand Tool

G2501 (or the older G317A) is required to crimp the

connectors onto the wires.

Strip away about 1‘I? of the cable sheathing and shield,

then strip the individual wires

about ‘kiP.

Crimp each

terminal onto a wire using Molex Model HTR-2445-A

91988 Rauland-borg Corporation . Printed in U.S.A. Page 1 of 4

Orig. lo/87 Rev. 4/88. 2d Printing 12/95.