output interfaces, which facilitates integration of the system with other

devices.

◼Remotecontrol and management is available.

◼Super combination ability, different styles, series channel products can be

combined without affectingsystemperformance.

◼Powerful system capacity expansion, new products can be added at anytime.

◼Remote control management: The state of the gate is operated remotely to

meetthespecial needs of users and fire safety requirements.

◼Powerful self-checking function: The device is in fault monitoring state at

any time. The error reporting function is friendly and the human-computer

interactionis convenient and quick to realize maintenance;

◼Good anti-collision function (when the gate is in the state of opening and

closing the door, when there is an object hit, the brake detects the object and

immediately stops moving and reverses back); the service life is up to 100-

200 million times.

◼Emergency-escape function: When power off, it will be opened the gates

automaticallyto meet the request of fire protection. Also the gates will open

by pressing the emergency button which can be remote-controlled whether

the power is on or not. (Optional).

◼Standard fire alarminput interface, requires N.C normally close contact.

◼The turnstile system can easily integrates with the 3rd party equipment with

read facilities, such as biometric reader, consumption system, ESD system

and access control systemetc.

◼The turnstile system can be hooked up with multiple reader equipments

together. Rapid identification technique, available to identify accurately and

efficientlythe magneticcard, bar codecard, ID/ICcard, fingerprint and

face detectionetc.

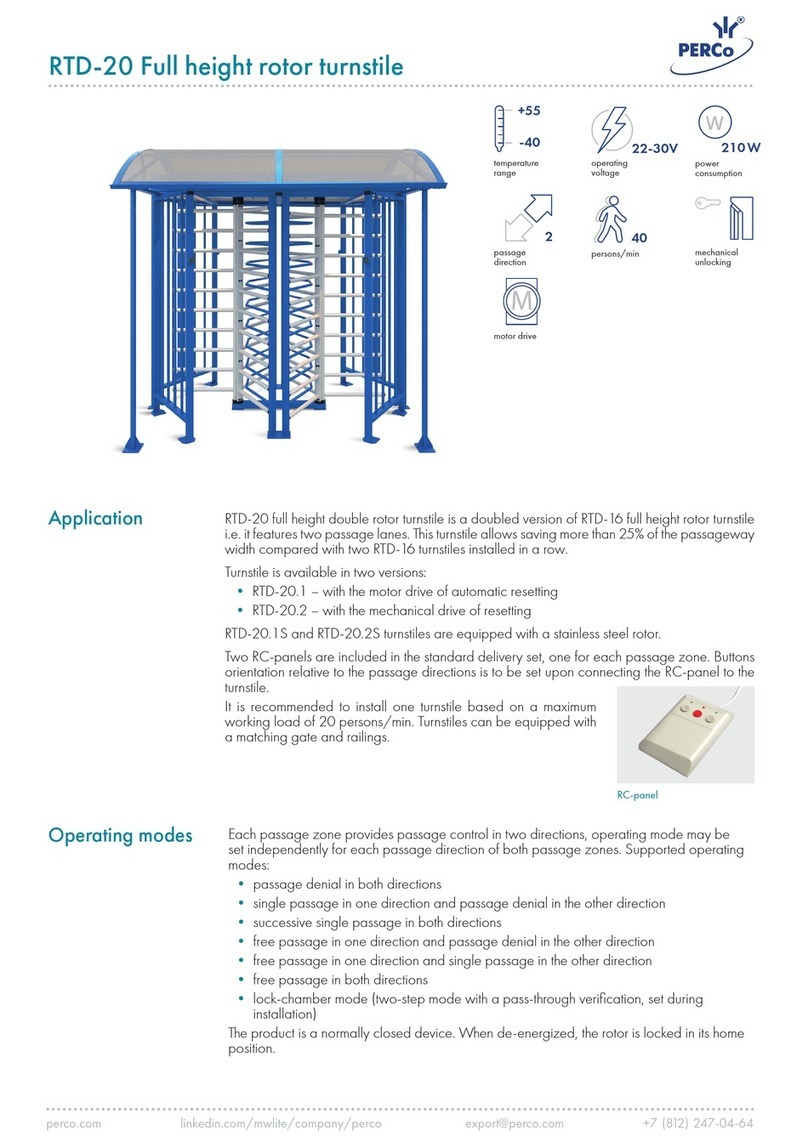

◼Operation model: Both directions can be set as controlled mode or freemode,

two or one direction can be controlled by switch- button or access controller.

◼Withnormally open & normally closed workingmode.

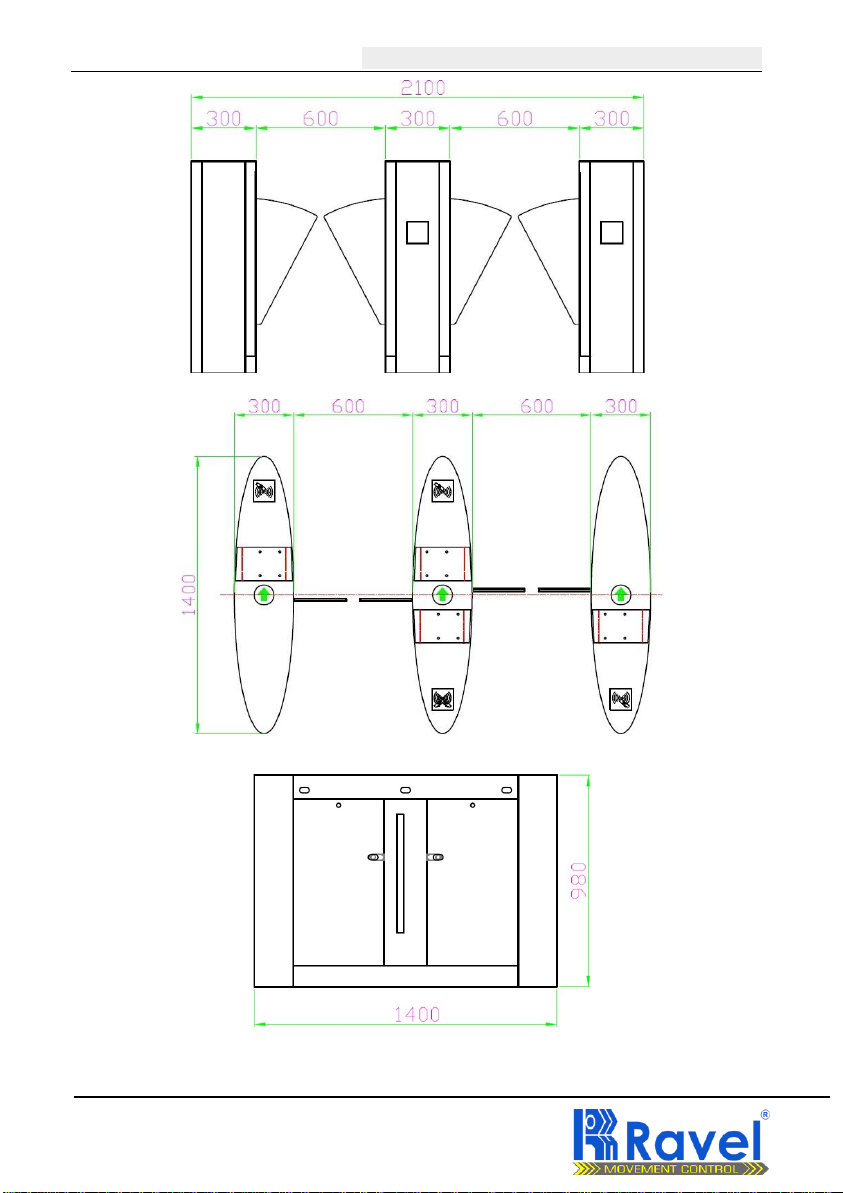

◼Passageway width at 1000mmavailable.