Raychem H910 User manual

Installation Instructions

H910

WinterGard®Splice and Tee Kit with End Seal

Description

The WinterGard®H910 Splice and Tee Kit is for use with WinterGard

self-regulating heating cables to make splice, tee, and end seal con-

nections. The kit contains materials for one splice and one end seal, or

one tee connection and one end seal. This kit does not provide a power

connection; use an H900 or H908 power connection kit for a complete

installation.

Applications

Use the H910 kit with the following WinterGard heating cables:

H311, H611, H612, H621, and H622. All are designed for pipe

freeze protection in dry locations, but H612 and H622 cables are

designed for both wet and dry areas, as well as for roof and gutter

de-icing. The cable type is printed on the outer jacket of the cable.

Tools Required

• Diagonal Cutters • Needle nose pliers

• Utility knife • Heat gun or torch

• Crimp tools (Ideal 30-425 and T&B WT112M or WT2000)

• Hammer and nail (for gutter/downspout applications only)

Installation and Support

The minimum installation temperature for this kit is 0°F (–18°C).

See the WinterGard Application and Design Guide (H53585),

H900, or H908 installation instructions for design information.

For additional technical support call Tyco Thermal Controls at (800)

545-6258.

R

E

A

B

C

D

E

H

G F

I

Approvals

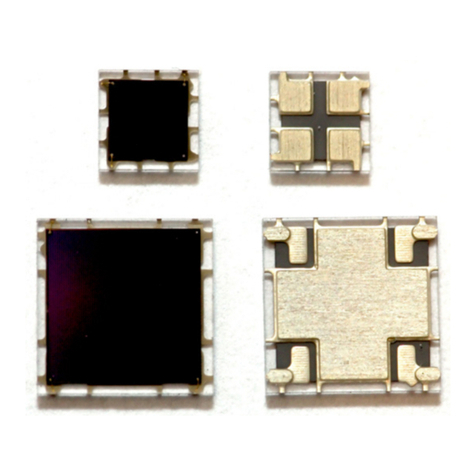

Kit Contents:

Item Qty Description

A 2 Insulated bus wire crimps

B 1 Uninsulated braid crimps

C 3 Cable ties

D 6 Mastic strips

E 1 Heat-shrinkable cap

F 1 Heat-shrinkable tube (6" long, 1" dia.)

G 1 Black cloth tape (6" long)

H 1 Clamp tie

I 1 End seal

WARNING:

This component is an electrical device that must be

installed correctly to ensure proper operation and to

prevent shock or fire. Read these important warnings

and carefully follow all the installation instructions.

• To minimize the danger of fire from sustained

electrical arcing if the heating cable is damaged

or improperly installed, and to comply with the

requirements of Tyco Thermal Controls, agency

certifications, and national electrical codes, ground-

fault equipment protection must be used. Arcing may

not be stopped by conventional circuit breakers.

• Bus wires will short if they contact each other. Keep

bus wires separated.

• Keep components and heating cable ends dry before

and during installation.

• The black heating cable core is conductive and can

short. It must be properly insulated and kept dry.

• Component approvals and performance are based on

the use of Tyco Thermal Controls-specified parts only.

Do not use substitute parts or vinyl electrical tape.

• Leave these instructions with end user for reference

and future use.

2

H910 Installation Instructions

12"

Bus wires

Core

Inner jacket

Braid

Outer jacket

(only on H612/H622)

2"

2"

1

The instructions are shown for a tee connection. Splice connections are done the same way, without the third heating cable section.

• Allow 12" of extra

heating cable as

shown. If necessary

trim cables evenly.

WinterGard Heating Cables

• H311, H611 and H621 do not have an

outer jacket. Proceed to Step #3.

• Lightly score completely around and

then down outer jacket.

• Bend heating cable to break jacket at

score then peel off outer jacket. Do not cut braid

or inner jacket.

23

1"

• At the end of

each heating-

cable section

lightly score

completely

around and

down inner

jacket.

• Bend heating cable to

break jacket at score, then

peel off inner jacket.

Do not cut

bus wires.

4

1/4"

1/4"

• Notch core at the end.

• Twist back and

peel bus wires

from core.

5

• For H612 and H622, unravel the braid back to the outer jacket. For

H311, H611 and H621, unravel the braid back 2 inches .

• Position braid on same side of each heating cable section.

• Straighten the braid and twist into a “pigtail”.

Splice or Tee Connections

3

H910 Installation Instructions

• Score between bus

wires at base jacket.

• Bend core to break

free at base jacket.

• Peel core and any

remaining material

from bus wires.

Repeat steps 2 through

6 for other heating cable

sections.

Do not cut

bus wires.

6

Mastic

1"

2"

Mastic

1/4"

Pinch

9"

6"

• Remove release paper

from mastic strip.

• Wrap a piece of

mastic around the

outer jacket on each

heating cable section.

• Remove release paper

from mastic strip.

• Wrap a piece of mastic

around the end of each

heating cable section

and position as shown.

• Pinch the mastic

in the center to

completely seal the

core at the end of

each heating cable.

• Carefully align the

heating cable sections

and place them together.

• Press mastic strips

firmly together.

• Fasten with a cable

tie at each of the two

positions shown.

7 8

9

4

H910 Installation Instructions

Place edge of

tube at edge

of mastic

Approx.

4-1/2"

6" tube

• Position the 6”-long heat-

shrinkable tube as shown.

14

1/4"

• Twist the braid

pigtails together.

• Slide uninsulated crimp over

braid to within 1/4” of heating

cable as shown.

• Crimp the braid, using the

Ideal crimp tool.

• Cut off the extra braid.

10

Black tape

• Fold the crimped braid back

against the heating cables.

• Wrap black cloth tape

evenly around crimp and

heating cables. Cover crimp

completely.

• Select one bus wire from

each cable section and

twist the wires

together.

• Repeat with remaining

bus wires.

Be careful not to twist

together bus wires from

the same heating cable.

• Use insulated bus wire

crimps and T&B crimp

tool to crimp each set of

bus wires together.

• Slide heat-shrinkable cap over bus

wire crimps.

• It is not necessary to shrink cap.

11

13

12

5

H910 Installation Instructions

Secure end of

connection to

heating cable

H915

Ring of mastic

and adhesive

will appear

• After the connection has cooled, fold

over the connection and fasten it

with the third cable tie.

• Secure heating cable with down-spout

hanger (H915).

• Fasten clamp tie to center of connection.

• Use a hammer, nail, and clamp tie to

secure connection and keep it off of the

gutter bottom as shown.

• Shrink the tube completely. Start at end farthest

from the cap and work toward the open end.

• Keep heating after tube has shrunk, to melt

adhesive and mastic inside tube. Total heating

time should be about 5 minutes.

Important: Additional heat

is needed after the tube is

shrunk to melt mastic and

adhesive inside.

• Immediately after

shrinking, pinch the end

of the tube with needle-

nose pliers until the

end stays sealed; this

normally takes

10 seconds.

15

16b WinterGard Wet gutter and downspout applications

16a For all applications except WinterGard Wet in gutters and

downspouts

CAUTION:

To avoid burns

allow heated

sections to cool

before touching.

6

H910 Installation Instructions

Note: The end seal is designed to be installed only once. It cannot be removed from the heating cable once it is installed. Do not install it until instructed to

do so in Step 3

1"

2

• Unravel and remove exposed braid.

3

• Cleanly cut off the end of the cable.

• Score down and around outer jacket

1 inch from the end.

• Remove the outer jacket.

• Do not cut or damage inner jacket

• Firmly push end seal onto the cable (at least 1½ inch).

Some gel may ooze out.

• Do not twist or try to remove the end seal during or after

insertion.

• Do not reuse an end seal.

1

End Seal Installation Instructions for H612 and H622 Heating Cables

© 2007 Tyco Thermal Controls Printed in USA P/N 585033 H55073 01/07

Worldwide Corporate Headquarters

Tyco Thermal Controls

2415 Bay Road

Redwood City, CA 94063-3032

Tel: (800) 545-6258

Tel: (650) 216-1526

Fax: (800) 527-5703

Fax: (650) 474-7711

www.tycothermal.com

Important: All information, including illustrations, is believed to be reliable. Users, however,

should independently evaluate the suitability of each product for their particular application.

Tyco Thermal Controls makes no warranties as to the accuracy or completeness of the informa-

tion, and disclaims any liability regarding its use. Tyco Thermal Controls' only obligations are

those in the Tyco Thermal Controls Standard Terms and Conditions of Sale for this product,

and in no case will Tyco Thermal Controls or its distributors be liable for any incidental, indi-

rect, or consequential damages arising from the sale, resale, use, or misuse of the product.

Specifications are subject to change without notice. In addition, Tyco Thermal Controls reserves

the right to make changes — without notification to Buyer — to processing or materials that

do not affect compliance with any applicable specification.

Tyco, Raychem and WinterGard are trademarks of Tyco Thermal Controls LLC or its affiliates.

7

Canada

Tyco Thermal Controls

250 West St.

Trenton, Ontario

Canada K8V 5S2

Tel: (800) 545-6258

Fax: (800) 527-5703

2

• Push the braid back 2 inches from the cable end.• Cleanly cut off the end of the cable.

• Firmly push end seal onto the cable (at least 1½ inch).

Some gel may ooze out.

• Do not twist or try to remove the end seal during or after

insertion.

• Do not reuse an end seal.

3 4

• Slide the braid up against the end seal and secure with the

6-inch length of tape provided.

H910 Installation Instructions

1

End Seal Installation Instructions for H311, H611 and H621 Heating Cables

Note: The end seal is designed to be installed only once. It cannot be removed from the heating cable once it is installed. Do not install it until instructed to

do so in Step 3

Table of contents

Popular Accessories manuals by other brands

Temperature alert

Temperature alert TM-ZP200 user guide

Leuze electronic

Leuze electronic ACR 300i Connecting and operating instructions

netvox

netvox RB11E user manual

MPE

MPE CHAIN-VEY Installation & operation manual

NVC

NVC Jupiter NJP/PLUG-IN/MW/SENSOR instructions

Wolf Garten

Wolf Garten SENSO instruction manual