Raychem TraceTek TTDM-2 User manual

R

TraceTek

Long-Line and Zone

Leak Detection and Location Systems

Operation and Maintenance Manual

For TTDM-1, TTDM-2, and TTDM-24

Alarm and Locating Modules

Belgium

NV Raychem SA

Diestsesteenweg 692

3010 Kessel-Lo

Tel (32) 16/351-800

Fax (32) 16/351-797

Korea

Raychem Korea Limited

831-45 Yeuksam-Dong

Kangnam-Ku

Seoul 135-080

Tel (82) 2/ 3468-1300

Fax (82) 2/ 558-5765

United Kingdom

Raychem Ltd.

Faraday Road

Dorcan, Wiltshire SN3 5HH

Tel (44) 1793/ 572-663

Fax (44) 1793/ 572-189

United States

Raychem Corporation

300 Constitution Drive

Menlo Park, CA 94025-1164

Tel (800) 553-1737

(415) 361-4900

Fax (415) 361-3215

© 1995 Raychem Corporation Printed in USA H55472-L PCN 137021 3/97 TraceTek is a trademark of Raychem Corporation.

All information, including illustrations, is believed to be reliable. Users, however, should independently

evaluate the suitability of each product for their application. Raychem makes no warranties as to the

accuracy or completeness of the information, and disclaims any liability regarding its use. Raychem’s only

obligations are those in the Raychem Standard Terms and Conditions of Sale for this product, and in no

case will Raychem be liable for any incidental, indirect, or consequential damages arising from the sale,

resale, use, or misuse of the product. Specifications are subject to change without notice. In addition,

Raychem reserves the right to make changes—without notification to Buyer—to materials or processing

that do not affect compliance with any applicable specifications.

R

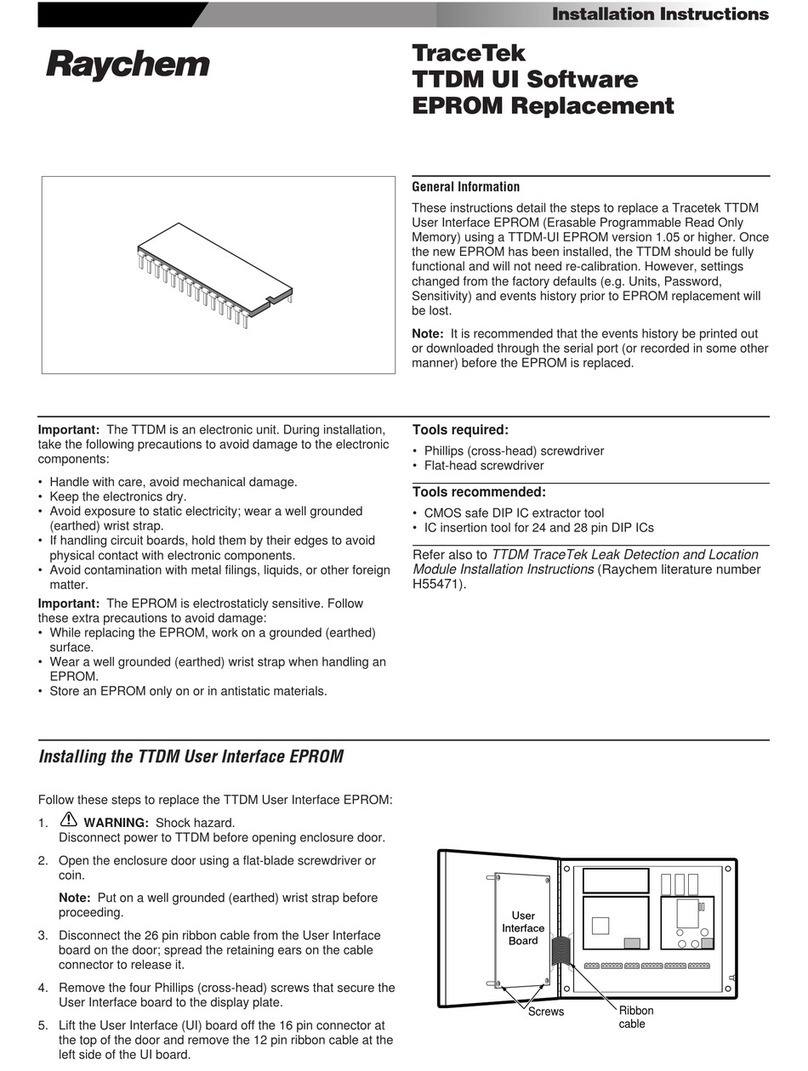

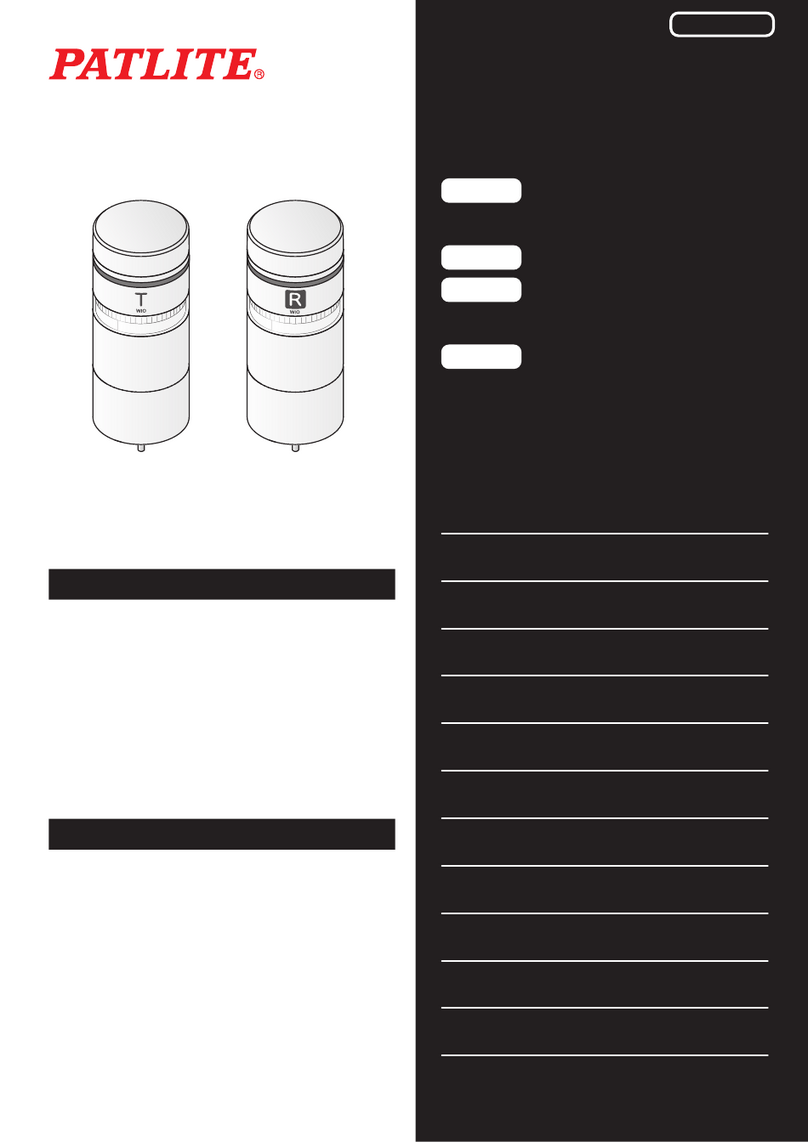

Identifying TTDM Features

External View [A]

(1) LCD display gives up-to-date

information regarding the condition of

the system.

(2) Icons and LEDs (light emitting

diodes):

Monitoring LED green

Service (Required) LED yellow

Leak LED red

Fault LED red

(3) (Self) Test key

Can be used at any time to

verify the correct operation of the

module. The module performs a

series of self-diagnostic checks.

(4) Silence key

Used to silence audible alarms

(5) Reset key

Used to reset the leak alarm relay

after a leak has been cleared.

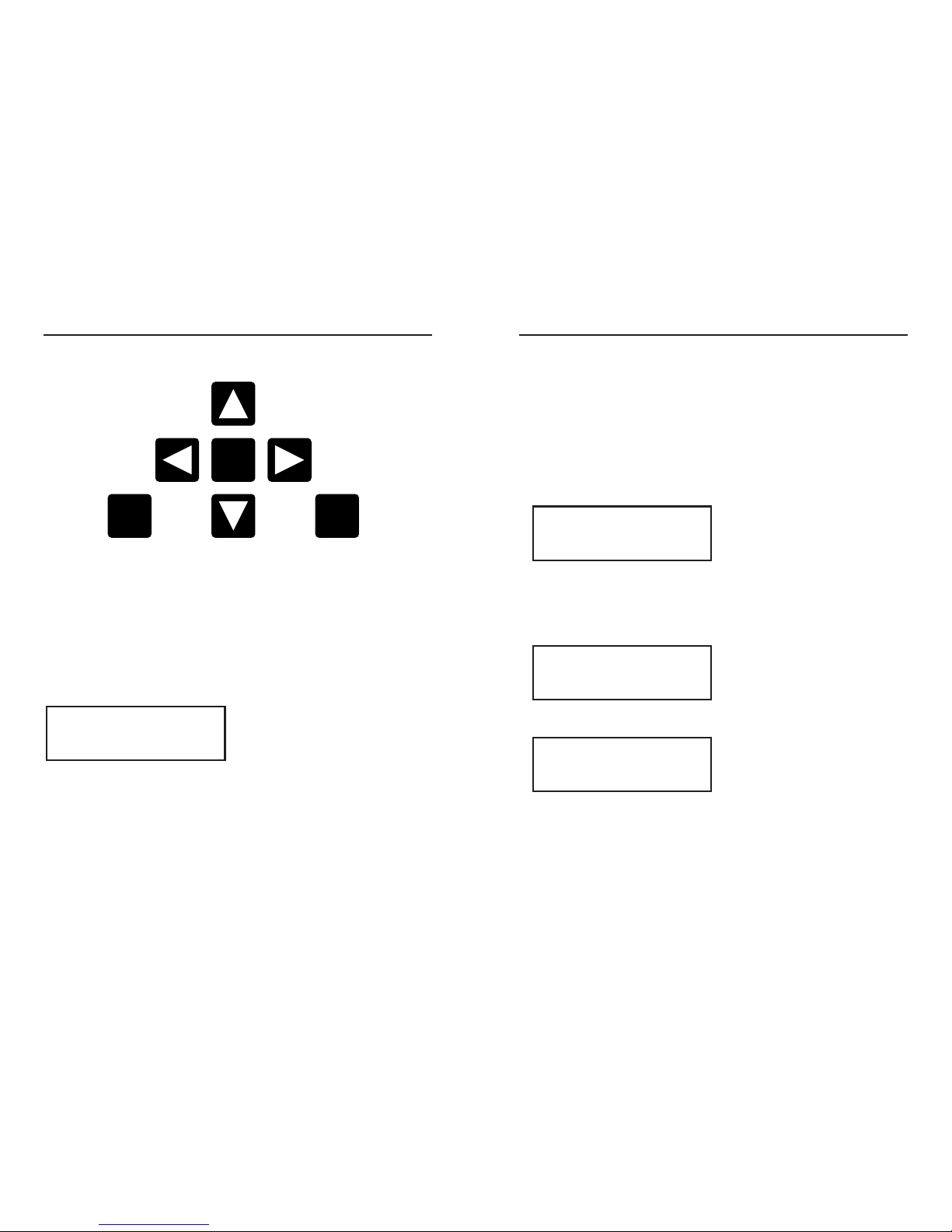

(6) Menu keys

The menu button provides access to

various features that may be viewed

and/or edited. The menus are navigated

with the arrow keys together with the

Esc (escape) and Enter keys.

Internal View [B]

(7) User interface board

(8) 4–20 mA board

(9) Sensor interface board

(10) Motherboard

(11) Power supply board

(12) Fuse (200 mA, 250 V)

(13) Power cable terminal block

(14) Ground (earth) stud

(15) Fault relay cable plug and socket

(16) Leak relay cable plug and socket

(17) Service relay cable plug and socket

(18) 4–20 mA port plug and socket

(19) RS-232/485 port plug and socket

(20) Sensing cable plug and socket

(21) Reserved for future use

(22) Ribbon cable

(23) Volume adjustment

(24) LCD contrast adjustment

ii

ResetTest

EnterEsc

Menu

RTraceTek

TTDM

1

2

6

34 5

7

23

24

98 10

11

13

12

14

151617

18

1920

22 21

A

B

i

Contents

1

Identifying TTDM Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Leak Detection System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Connection to Other Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

The Basic Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Leak Detection and Location Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Service Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Fault Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Multiple Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Navigating the Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

The Events History Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Diagnostics (System Status) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Changing Settings (View/Edit Settings) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Appendix 1 - Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Appendix 2 - Events Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Appendix 3 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Appendix 4 - Interface Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Appendix 5 - Wiring Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Appendix 6 - TraceTek Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Please read before use

Please read these instructions carefully and keep in a safe place (preferably close to the

module) for future reference.

The instructions provided in this booklet must be followed carefully to ensure proper

operation. If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

Description

The TTDM module has been specifically designed for use with TraceTek sensing cables

(all TT1000, TT3000, and TT5000 series sensing cables, and all TT100, TT300, and TT500

series long-line sensing cables). TTDM can monitor up to 5000 ft (1500 m) of sensing

cable and can detect and locate the presence of liquid at any point along the cable. The

module also monitors the system for other alarm conditions:

• Service required

•Fault

Each “event” (service, leak, or fault) is recorded in an Events History with the time and

date of occurrence. This allows easy tracking of events.

Preparation

Before operation, the instructions in the “TTDM Installation Instructions” that accompany

the system must be followed so that the module is properly:

• Mounted

• Powered (wired and energized)

• Connected to a TraceTek sensing cable with a TraceTek jumper or leader cable

• Commissioned (a completed commissioning form should be supplied)

If these steps have not been taken, please refer to the “TTDM Installation Instructions” in

order to complete the installation.

In addition, there should be a system map, which indicates the sensing cable layout with

reference landmarks throughout the system.

Notes

• Throughout this manual, the examples shown use distances in feet.

• Later versions of software may provide new features and change certain other details.

This manual documents UI Version 1.05.

Introduction

iii

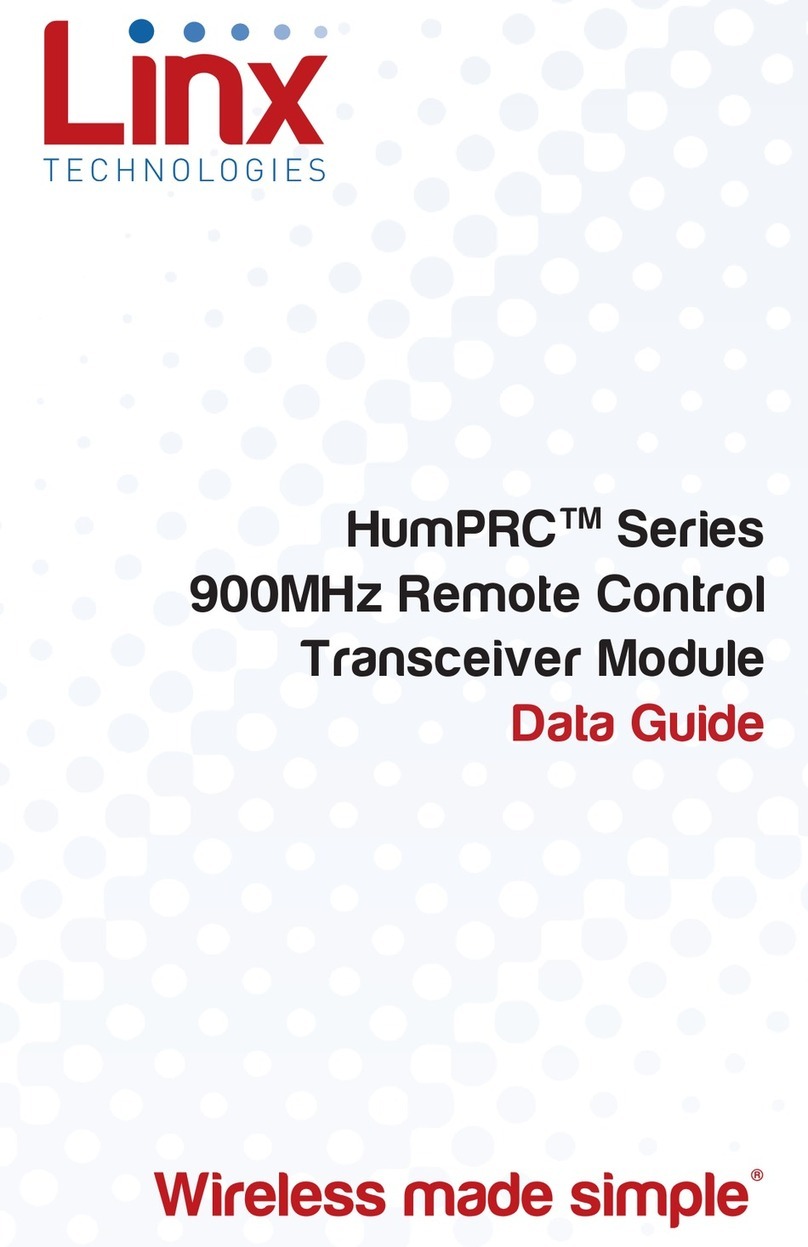

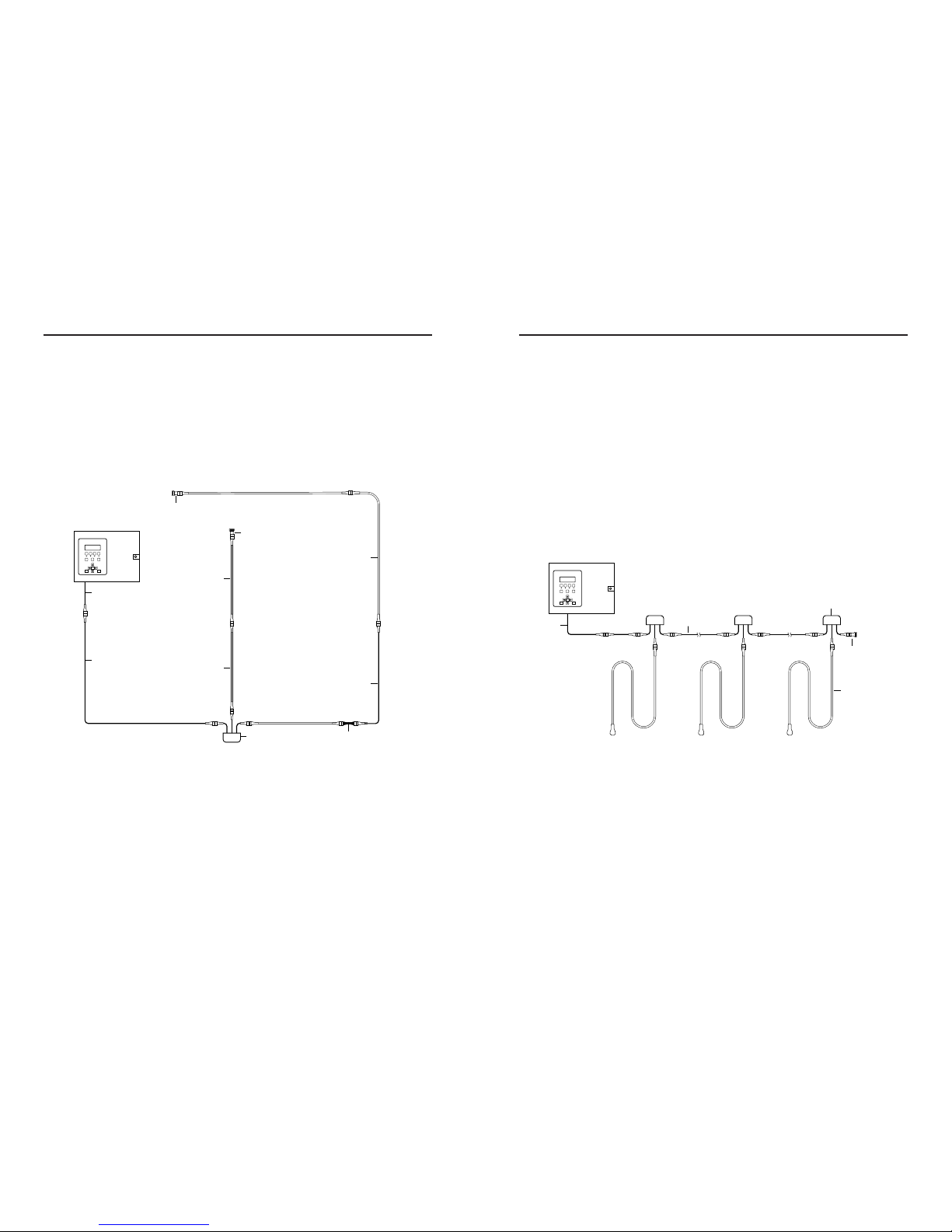

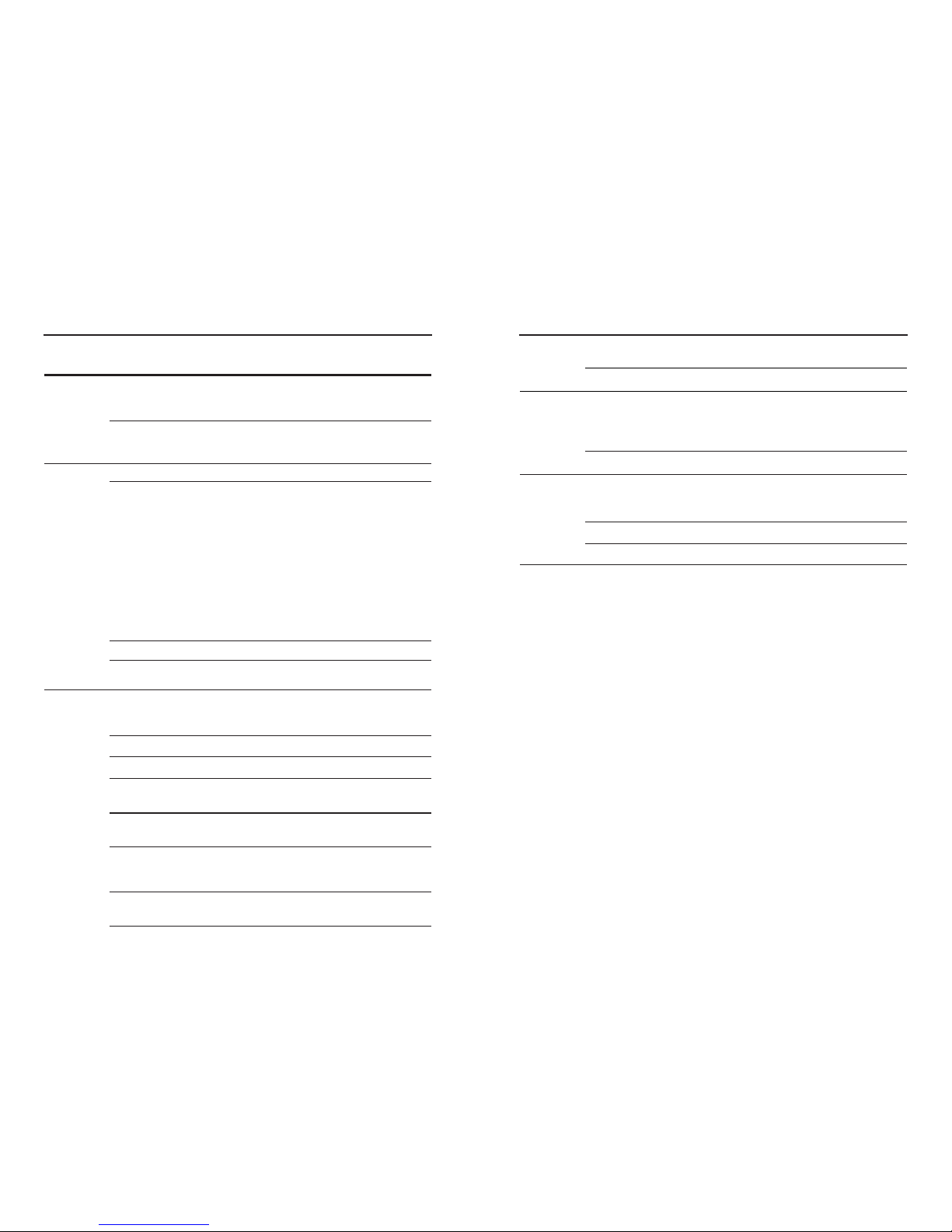

The TraceTek Zone System

The TraceTek zone system is a leak detection and location system that monitors many

separate locations from one point. The zone system consists of the TTDM Alarm and

Locating Module and up to 100 separate sensing zones interconnected by one run of

jumper cable.

Each sensing zone consists of a zone connector and one 5 ft (1.5 m) length of sensing

cable. If liquid is detected, the module signals the alarm and displays the zone where the

leak has occurred. The zones are numbered sequentially by the system electronics.

Important: In a TraceTek zone system, only

zone

sensing cables (TT3000 zone or

TT5000-series zone) may be used. Each sensing cable plugs into a zone connector.

The last zone connector must have an end termination.

ModeResetTest

Test

POWER

ON ZONE1

ON ZONE2

ON ALARM

EnterEsc

Menu

RPROTRAC2

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

TTDM

Alarm and

Locating Module

Zone

sensing

cable

Jumper

cable

End

termination

Zone

connector

Modular

leader

cable

TraceTek Longline System

A TraceTek longline system provides distributed leak detection and location to monitor

long lengths and wide areas. The system consists of the TTDM Alarm and Locating

Module and up to 5000 ft (1500 m) of sensing cable.

The sensing cable detects liquid at any point along its length. The module then signals the

alarm and displays the distance to the leak.

The longline system includes sensing cable and circuit components (leader cable, jumper

cables, end terminations, weighted lengths, and branching connectors) with connectors

that allow components of the system to plug together.

The weighted length resistor simulates a 15 ft (5 m) length of sensing cable. Installed at

the boundary between two areas, it allows the user to clearly identify the area where the

leak has occurred.

The branching connector enables the sensing cable to be branched. An end termination

completes each branch. At the branching connector, the system first counts the sensing

cable along the branch (middle connector), before it continues with the main run. Two

built-in 15 ft (5 m) weighted length resistors allow the user to clearly identify on which

leg a leak has occurred near the branching connector.

An important part of the TraceTek longline system is the system map, a sensing cable

layout plan with actual distance readings. Thus, in case of an alarm, the location of the event

can be determined quickly. The map should be placed near the Alarm and Locating Module.

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / // / / / / // / /

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / // / / / / /

ModeResetTest

Test

POWER

ON ZONE1

ON ZONE2

ON ALARM

EnterEsc

Menu

RPROTRAC2

/ / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / // / / / /

TTDM

Alarm and

Locating Module

Modular

leader cable

Jumper

cable

Modular

branching

connector

Weighted

length

Jumper

cable

Sensing

cable

End

termination Modular end

termination

Sensing

cable

Sensing

cable

2 3

Leak Detection System Description

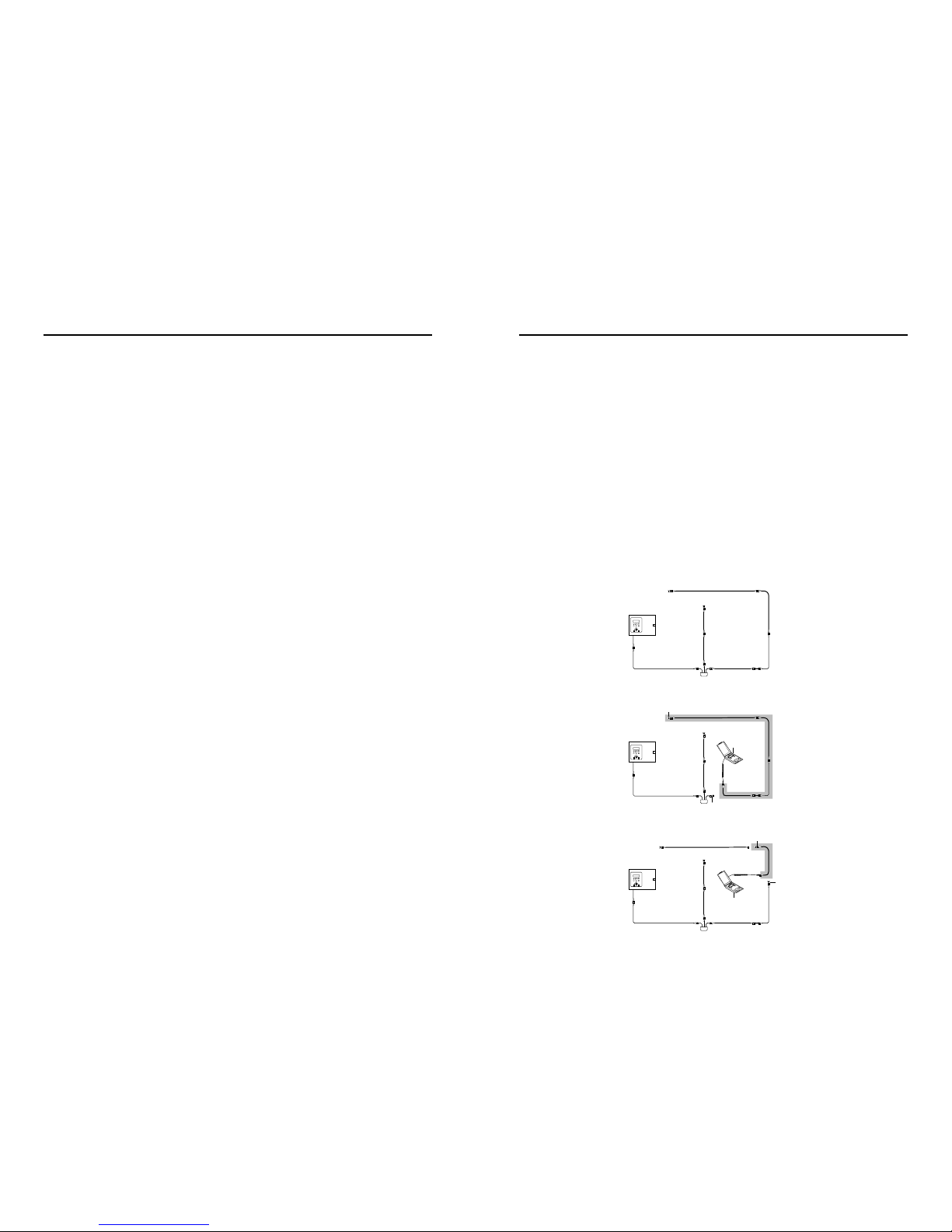

Serial Port

The TTDM module has a serial port (marked EXT COM PORT) that can be configured for

use either as an RS-232 or RS-485 transceiver. The factory default is RS-232, and is

suitable for connecting the TTDM to single devices up to 50 ft (15 m) away. The standard

configuration is RS-232 full-duplex with no hardware handshaking, which is suitable for

connection to many devices (such as a remote host PC, laptop, or modem).

The RS-232/485 port (19 on foldout) is connector J13 on the TTDM motherboard. The

pinouts for connector J13 on the TTDM motherboard are listed below, with functions for

RS-232 usage noted.

Pin Desc. Use

J13-5 RX/A Receive data

J13-6 TX/B Transmit data

J13-7 RTS Request to send —

for hardware handshaking

J13-8 CTS Clear to send —

for hardware handshaking

J13-9 +5V/DTR +5V supply/DTR if

needed by modem

J13-10 GND Supply return

Note: For further information, see Appendix 4 - Interface Details.

Relays

TTDM has three relays:

• Service

• Leak

• Fault

Each relay provides two Form-C relay contacts, with normally open and normally closed

contacts both provided. The relays are

de-energized to indicate an alarm

condition. The

diagram below shows the relay status when each is in an alarm (de-energized) state.

(For other connection options, please consult Appendix 5 - Wiring Details.)

4–20 mA

The module is equipped with an analog 4–20 mA interface. The TTDM adjusts its current

output based on whether an alarm condition exists, and (when a leak is detected) the

location of the leak. Its output can be scaled to make full use of the 4–20 mA range for

the length of sensing cable connected.

Note: The current transmitter is isolated from the sensing circuitry and therefore requires

an external 24 Vdc power supply.

The 4–20 mA output port (18 on foldout) is connector J2 on the TTDM motherboard,

with terminals as noted in the following table:

Pin Desc. Use

J2-11 IRTN Current loop return

J2-12 IOUT Current output

J2-13 +V 24 Vdc supply (required)

J2-14 +VRTN 24 Vdc common (required)

Note: More information about operation and testing is found in Appendix 4 -

Interface Details.

15 16 17 201918 21 22 23 262524 27 28 29 323130

LEAK RELAYSERVICE RELAY FAULT RELAY

4 5

Connection to Other Devices

Leak

When liquid is detected on the sensing cable, this red Leak LED illuminates. Note that the

green LED remains illuminated; the unit continues to monitor for leaks and spills. This is cov-

ered more fully in the following section “Leak Detection and Location Events”, on page 8.

Fault

When the TTDM module detects a fault—either a cable fault, or an electronics fault—it

lights this red LED. Note that in a Fault condition, the TTDM module is unable to detect a

leak. For further information, see the “Fault Events” section on page 12.

LCD Display

Line 1 indicates the original location of a leak.

Line 2 indicates the present status (except when a leak is initially detected, since the ini-

tial location is always shown on line 1).

Line 3 may advise action or provide special instructions.

Line 4 displays the current time and date (the colon blinks once a second). To highlight

the present status, the line of the display with the most recent event flashes.

Hint: The LCD contrast may be adjusted (24 on foldout).

Leak 10 ft

Leak Cleared

Press Reset

16:30 14-Feb-1996

The Icons

The Icons (2 on foldout) represent the four main states of the TTDM module:

Monitoring

This green LED indicates that the TTDM is monitoring the sensing cable. If something

happens that makes it impossible for the TTDM to monitor the sensing cable (for exam-

ple, the cable is broken), the Monitoring LED will extinguish.

Service

The TTDM is able to give advance warning of potential problems. This yellow Service LED

illuminates to indicate that service is required. Note that the green LED remains illuminated;

the unit continues to monitor for leaks during a Service alarm.

See the “Service Events” section on page 10 for further details.

Monitoring

Service

Leak

Fault

Green Yellow Red Red

6 7

The Basic Events

To Locate the Leak

Using the number displayed by the TTDM, refer to the system map and determine where

the leak was detected.

To Clear the System

Fix the leak and cleanup the area affected. Then dry the sensing cable (in the case of

TT1000 and TT3000) or replace the tripped section (TT5000 family).

Once the sensing cable is clear, the module responds and the display changes:

Notice that the red LED remains on. This is to indicate that the leak relay is still in the alarm state.

To Reset the Leak Relay

In order to reset the leak relay and return the module to the “System Normal” state, press

the reset button. Before doing so, check that any external or remote equipment controlled

by the TTDM is ready to be reset.

Hint: If manual reset is not required, the module can be set to auto-reset

(see “Auto-Reset” under “Leak Settings” on page 23).

Once the Reset button is pressed, the relay returns to normal, the red Leak LED

extinguishes, and the LCD display changes:

System Normal

16:53 14-Feb-1996

Leak 10 ft

Leak Cleared

Press Reset

16:30 14-Feb-1996

If the TTDM unit has been installed correctly, and the system is clear, the LCD display will

appear as follows:

Leak

When liquid is detected, the following occur:

• The audible alarm sounds.

• The red Leak LED illuminates.

• The interfaces (relays, 4–20 mA, serial port) respond.

• The display changes to show the location of the leak:

The following actions should be taken:

• Silence the alarm.

• Locate the leak.

• Clear the system.

• Reset the leak relay.

To Silence the Alarm

Press the Silence key to silence the audible alarm.

Hint: If audible alarms are not required, the module can be set to disable them (see

“Audible Alarm” under “Leak Settings” on page 23).

Leak 10 ft

16:00 14-Feb-1996

System Normal

15:53 14-Feb-1996

8 9

Leak Detection and Location Events

The number in square brackets indicates the estimated location of the material causing

the alarm. The number is shown with square brackets to indicate that the value is only an

estimate.

Hint: Because the cause (concrete dust for example) of low-level current may be distrib-

uted over several feet/meters of cable, it is not always possible for the TTDM to return an

accurate location. However, the indicated location is always a good point from which to

begin a troubleshooting procedure.

The following actions should be taken:

• Silence the audible alarm.

• Clear the cable.

To Silence the Audible Alarm

Press the Silence key to silence the alarm.

To Clear the Cable

Investigate the cause of the alarm and conduct cleanup or maintenance accordingly.

Hint: If material causing a service alarm is spread throughout the system, it is often

useful to subdivide the system; see Appendix 3 - Maintenance, for further information.

When the material (such as moisture or concrete dust) or conditions causing the alarm

are removed, the yellow LED goes out, and the service relay returns to its normal state:

System Normal

16:57 14-Feb-1996

Introduction

A TraceTek sensing circuit consists of two electrical loops (a diagram of the sensing

circuit is shown in Appendix 6). The TTDM module constantly monitors to see whether

current is passing between the loops. When the system is normal, there is no current

passing between the loops. When there is a leak on the system, the maximum current

flows (just 270 µA; the sensing cable operates on low voltage and is safe to touch).

If, however, the TTDM module detects a lower but significant level of current flow

between the loops, it activates the Service alarm.

A low-level current could indicate one or more of the following:

•A very small leak (which may soon develop into a full leak alarm).

• Heavy condensation or small spills (coffee, tea, etc.) on a water-sensing or aqueous-

chemical-sensing cable (TT1000 and TT3000).

•Conductive material on a water-sensing or aqueous-chemical-sensing cable. The

material might be metal filings, concrete dust, flux, mastic, or other construction

debris, or carbon-based dust from air-handling units, printers, or copiers.

While it is recommended that service alarms be investigated, the operation of the system

is not threatened; the TTDM will continue to detect leaks. However, the accuracy of loca-

tion may be affected in certain cases.

The Service Alarm

When a condition requiring service (such as described above) is detected, the following

occur:

• An intermittent beep sounds.

• The yellow Service LED illuminates.

• The service relay goes to alarm condition.

•The LCD display changes to the following:

Service ReqÕd [11]

15:53 14-Feb-1996

10 11

Service Events

To Remedy the Problem

Find the problem and rectify. This may mean reconnecting the cable, or finding the dam-

aged section and replacing it. If the cause of the fault is not obvious by visual inspection,

it is often useful to subdivide the system and test individual sections with a TraceTek

Portable Test Box.

As soon as the fault is rectified, the relay, LED, and LCD screen return to their

normal state:

System Normal

15:53 14-Feb-1996

Introduction

Several conditions could lead to a fault alarm:

• A cable is disconnected.

• A cable is damaged.

• A connection is damaged.

• There is a problem with the module.

What the Module Does

The following shows how the alarm display would appear if the fault were caused by a

broken or disconnected cable. (The TTDM would display a different message for a differ-

ent type of fault, such as a loss of continuity in only one of the sensing loops):

When a fault condition is detected, the following occur:

• An audible alarm sounds.

•The green Monitoring LED turns off (no longer able to detect a leak).

• The red Fault LED turns on.

• Interfaces react.

The following actions should be taken:

• Silence the audible alarm.

• Remedy the problem.

To Silence the Audible Alarm

Press the red Silence key to silence the alarm.

Cable Break

17:53 14-Feb-1996

12 13

Fault Events

Example (continued):

Before the problem can be dealt with, the leak spreads. Once the module has detected

significant movement (that is, greater than the Re-Alarm distance—see “Re-alarm dis-

tance” on page 23 for more detail), the module goes into alarm once again:

The LCD now displays the FIRST leak and the MOST RECENT alarm. The FIRST recorded

leak is likely to be close to the source of the leak.

The MOST RECENT leak shows the current “electrical center” of the liquid (essentially a

weighted average). If the re-alarm number is close to the first (as in the example above),

it is likely that the leak has spread.

Should the leak continue to spread, the TTDM would re-alarm again; the second line is

updated again:

Hint: Use the Events History to track the events between the “first leak” and the “most

recent event.” See “The Events History Log” section on page 19.

Leak 50 ft

Re-Alarm 60 ft

16:23 14-Feb-1996

Leak 50 ft

Re-Alarm 55 ft

16:01 14-Feb-1996

In addition to storing all events in memory, TTDM gives a direct indication of multiple

events, that is, events which happen after an initial leak but before the module is manually

reset.

The first line of the display always indicates where the liquid was first detected.

This location is the most useful in identifying the source of the leak.

The second line displays the most recent event. For example:

The second line flashes to highlight the present status. If the cable is then disconnected,

the display will change again:

Notice that the first line remains unchanged. The second line changes to reflect the

present condition of the system.

Moving Leak

The TTDM continues to monitor during “service” and “leak” alarms, ensuring that the

installation is afforded full-time protection.

The TTDM will re-alarm when the leak moves more than the re-alarm distance, for which

the default is 5 ft (1.5 m). The audible alarm will sound, the second line of the LCD will

change, and a new event will be added to the Events History.

Example:

Suppose a leak is detected at 50 feet:

Leak 50 ft

15:59 14-Feb-1996

Leak 11 ft

Cable break

15:53 14-Feb-1996

Leak 11 ft

Re-Alarm 20 ft

15:53 14-Feb-1996

14 15

Multiple Events

Note how this leak event differs from the simpler leak event detailed on page 8:

• Rather than displaying the message “Leak 50 ft,” the display puts the location in square

brackets. This indicates that 50 ft is the likely location of the leak.

Case 2 - Service, then leak at same location

If a leak is detected at nearly the same location as that causing a Service Required alarm,

TTDM operates differently, as shown below.

First, there is an alarm for Service Required.

Subsequently, a full-fledged leak is detected at nearly the same location. The TTDM

responds as shown below:

Since the Service Required alarm was at the same location, it is interpreted as an early

indication of the leak. The TTDM therefore clears the service alarm, and displays the leak

location without brackets.

Leak 239 ft

17:45 28-Feb-1996

Service ReqÕd[237]

16:53 28-Feb-1996

16 17

Additional Leak

If liquid contacts the sensing cable away from the initial leak, the module will re-alarm. If

the location is distant from the last alarm, the TTDM shows a location in square brackets.

Brackets indicate that the value shown requires interpretation; when an additional leak

occurs, the value represents the “electrical center” of the leaks.

The display also prompts the user to check the Events History log in order to investigate

the sequence of events between the first leak at 50 ft, and this re-alarm event.

Service-to-Leak Alarm

Case 1 - Different locations

Although TTDM can continue to monitor when a Service Required alarm is in effect, the

accuracy of location may be impaired. TTDM indicates this by displaying the leak location

in square brackets.

Example:

If a leak contacts the sensing cable before service was performed, the display would

appear as below:

Leak [50]

15:53 14 Feb 1996

Service ReqÕd[2003]

15:53 14-Feb-1996

Leak 50 ft

Re-Alarm [1045]

15:53 14-Feb-1996

One extremely useful function provided by TTDM is the ability to record a series of

events. The TTDM module keeps track of a list of 512 events.

For a full list of event types, please refer to “Appendix 2 - Events Glossary” on page 26.

Accessing the Events History Log

• Press Menu.

•Select Events History (scroll down with the down arrow key).

• Press Enter.

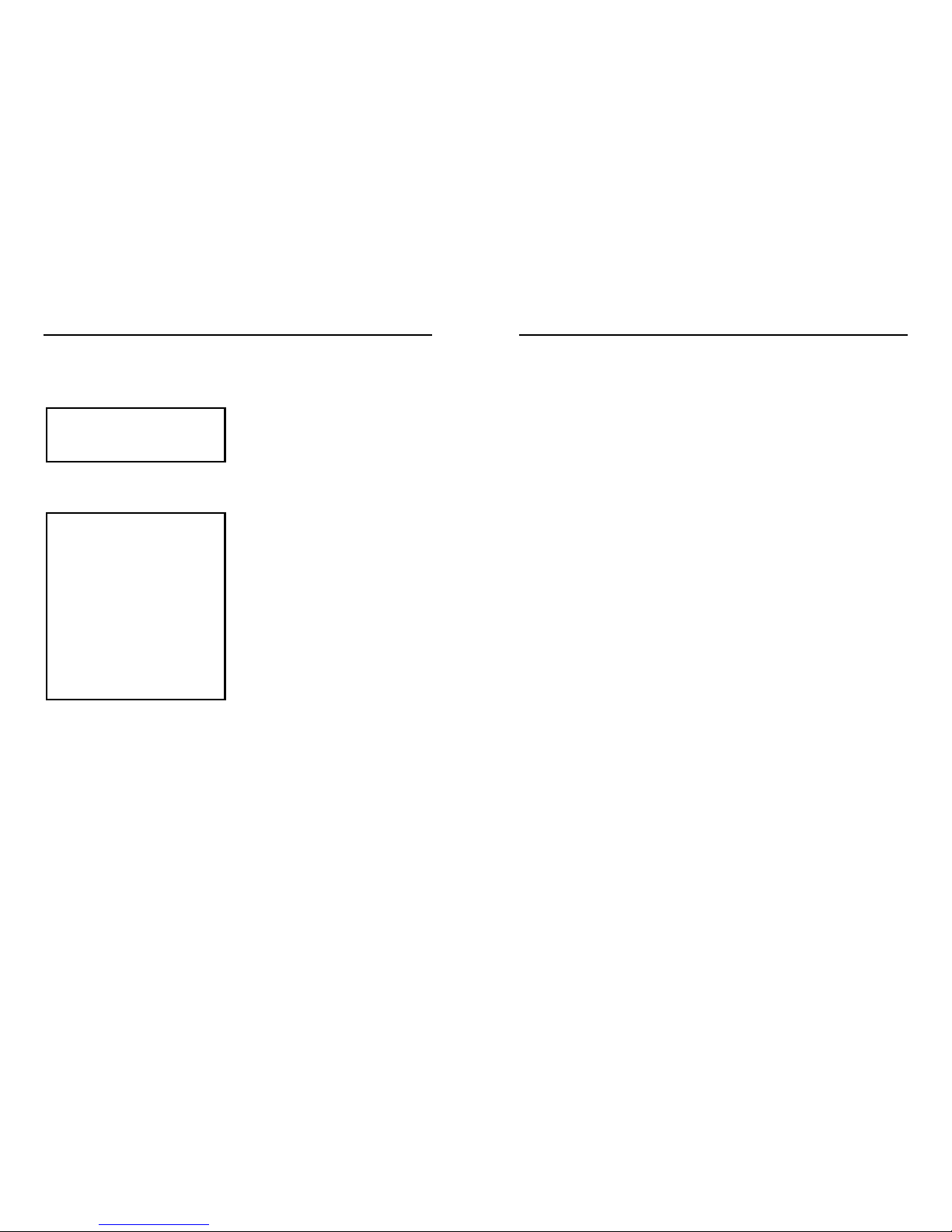

The most recent (that is, current) event is displayed:

The arrow at the bottom right-hand corner indicates that there are further events

‘below’ (= before) this one. The bottom line of the display indicates that the unit has

recorded 23 events, and the one displayed is the most recent event.

• Press Down Arrow key. The previous event is displayed:

• Press Down Arrow key again. The third from last event is displayed:

Hint: To quickly move to a view of the most recent event, press the Right-Arrow key.

To move to the oldest event, press the Left-Arrow key.

The TTDM can store up to 512 events. If 512 events are already stored, the oldest event is

discarded as a new event is registered. When this has occurred, the Events History leaves

the bottom line of the display blank. Contact Raychem for assistance if you wish to clear

the event history.

Events History:

▲

Leak 250 ft

■

09:01 13-Feb-95

■

[21 of 23]

▼

Events History:

▲

Leak Cleared

■

11:33 15-Feb-95

■

[22 of 23]

▼

Events History:

■

* Reset

■

09:01 17-Feb-95

■

[23 of 23]

▼

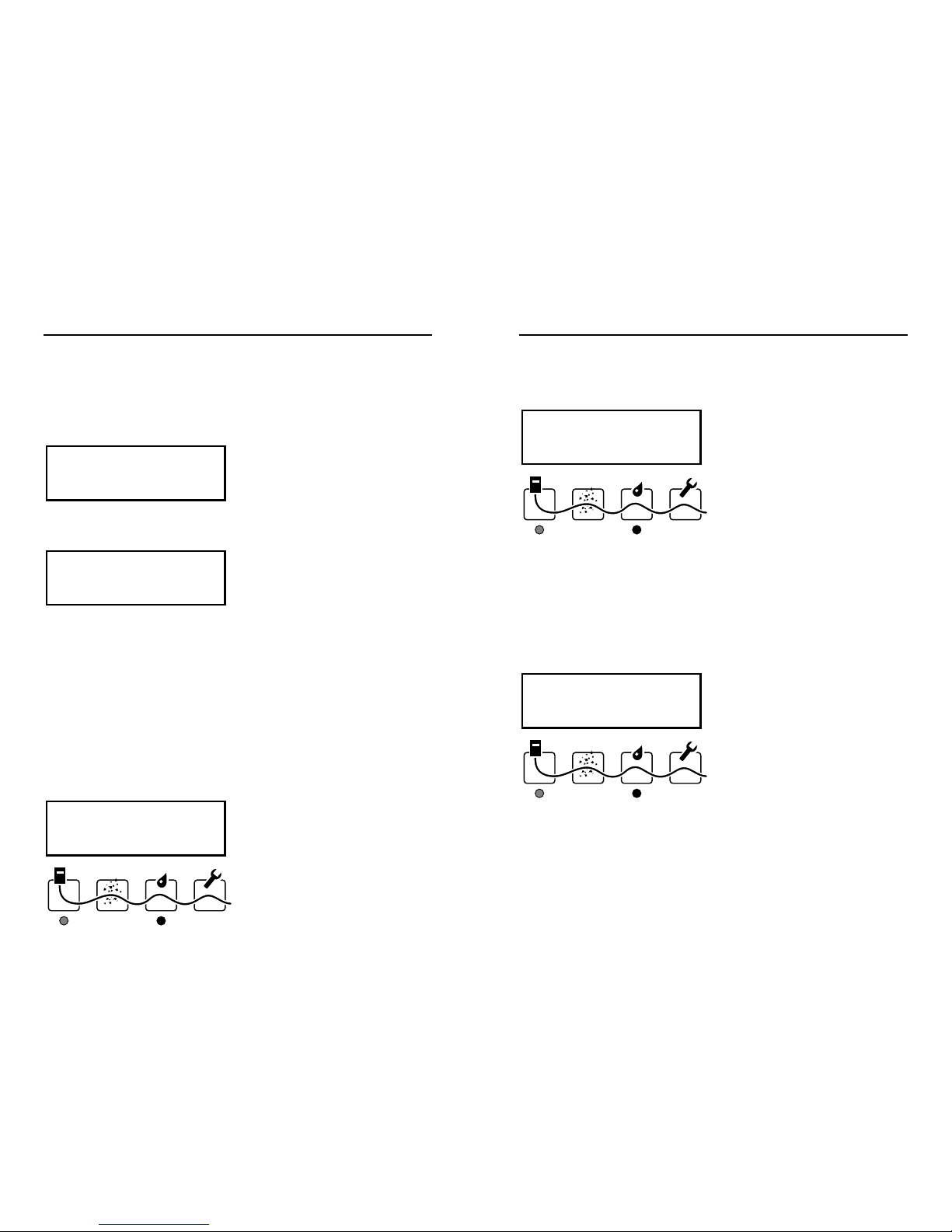

Please refer to “Appendix 1 - Menu Structure” on page 25 for an overview of the menu

structure and to item 6 on the foldout for the menu keys which are also shown below:

Start by pressing the Menu key.

Use the four arrow keys to scroll through menu items, and to select individual characters.

To go one level deeper into the menu structure, press Enter.

To go back one level in the menu structure, Press Esc.

The Scroll Bar

The scroll bar (see example below) indicates that there is more information off screen; the

arrow indicates the direction of further information:

View/Edit Settings

■

General

■

Leak

■

Ports

▼

EnterEsc

Menu

18 19

The Events History LogNavigating the Menu Structure

Location

The current location—or electrical center—of the leak (or cause of a Service alarm). If the

status is System Normal, the Location entry is blank.

Current

This current (measured in µA) indicates the condition of the sensing cable. If a leak is detected,

this rises to 270 µA. In a clean, leak-free system, the current should be 5 µA or less. If the cur-

rent rises above 20 µA, service is recommended, as it may indicate the presence of contamina-

tion. To better understand what this current means, see “Appendix 6 - TraceTek Technical Data”,

which explains the TraceTek operating principle.

R S-to-S

This is the resistance from sensing wire to sensing wire (see Appendix 6 for detail). For a

clean, leak-free system, this resistance is in the M½range. If liquid is detected, it drops to

the k½range or even lower. If the value is changing, it may indicate an event in progress.

R RG Loop, R YB Loop

These are the resistances of the Red-Green and Yellow-Black loops in the TraceTek sens-

ing circuit (see Appendix 6 for detail). If these values are significantly different from each

other, it may indicate damage to a sensing cable or connector.

SI Version, UI Version

These indicate the versions of the sensor interface and user interface software that are

operating.

The next line in the display was left blank intentionally because the entries that follow are

unlikely to be used except for reference in troubleshooting.

R Loc

This is the resistance measured along the black sensing wire to the location of the leak

(see Appendix 6 for detail).

SI Status, UI Status

These hexadecimal values indicate the current status of the Sensor Interface and User

Interface, respectively, and may assist factory personnel providing diagnostic support.

SI Comm

This indicates the success rate (in percent) for communications between the Sensor

Interface and User Interface boards. A value below 90% may indicate a faulty connection

or damaged ribbon cable.

System Status

System Status provides a real-time view of the system. You gain access to this feature

through the main menu. When System Status is selected, the TTDM displays the follow-

ing screen (the “{system status}” entry on the second line is explained below):

The arrow at the bottom right indicates other entries can be accessed with the down

arrow key. The complete list of information available in System Status is shown below:

“{system status}”

This is a variable field, which can contain any of the following text, depending on the state

of the system:

• System normal

• Leak

• Re-alarm

• Service Required

•Fault (specific entries are shown in Appendix 2)

Test Length

The Test Length should be the same as that recorded when the system was mapped. If it

is not, it may mean that the system was modified (sensing cable was removed or added).

Note: The Test Length is typically about 1% longer than the physical or mapped length of

the system. This is normal.

System Status

{system status}

Test Length 4785 ft

Location ----- ft

Current 0 µA

R S-to-S ----- k½

R RG Loop 18658 ½

R YB Loop 18656 ½

SI Version 100

UI Version 105

R Loc 0 ½

SI Status 1024

UI Status 1024

SI Comm 100

System Status:

■

{system status}

■

Test Length 4785 ft

■

Location ----- ft

▼

Diagnostics (System Status)

20 21

Language

Select from available options (English, Français,...)

Change Password

Enter the new password (using the arrow keys) and press Enter.

Don’t forget your password! Write it down in a safe place!

Hint: If password protection is not required, set the password to 0000. After that, you

will not be prompted for a password.

Leak Settings

You gain access to the Leak settings through the View/Edit Settings Menu, which is on

the main menu (see page 25 for the menu structure).

Re-alarm distance

This is the distance over which the electrical center of the leak must move before TTDM will

re-alarm. It can be set between 3 ft (1 m) and 20 ft (6 m); the factory default is 5 ft (2 m).

Re-alarm interval

The TTDM can be made to re-alarm automatically if a leak has not been cleared after a certain

length of time. Choose from:

•Never (factory default)

• 8 hr

• 12 hr

• 24 hr

Hint: Use this to automatically alert the next shift when the system has an uncleared leak.

Auto-reset

By default, TTDM requires a manual reset following a leak event. This allows the user to,

for example, verify that any equipment controlled with the Leak relay is ready to be

switched back on.

TTDM can be set to “auto-reset” following a leak. In this case, the leak relay will revert to

the normal state as soon as the leak has been cleared.

• Select: Auto-reset – On

Audible alarm

The audible alarm may be disabled if not required.

• Select: Audible Alarm – Off

Hint: The volume may be adjusted (23 on foldout).

You gain access to the system’s settings through the View/Edit Settings Menu, which is

on the main menu (see “Appendix 1 - “Menu Structure” on page 25). Four types of set-

tings are available:

• General

• Leak

• Ports

• Self-Test

In certain parts of the menu structure, settings may be changed only after entering a password.

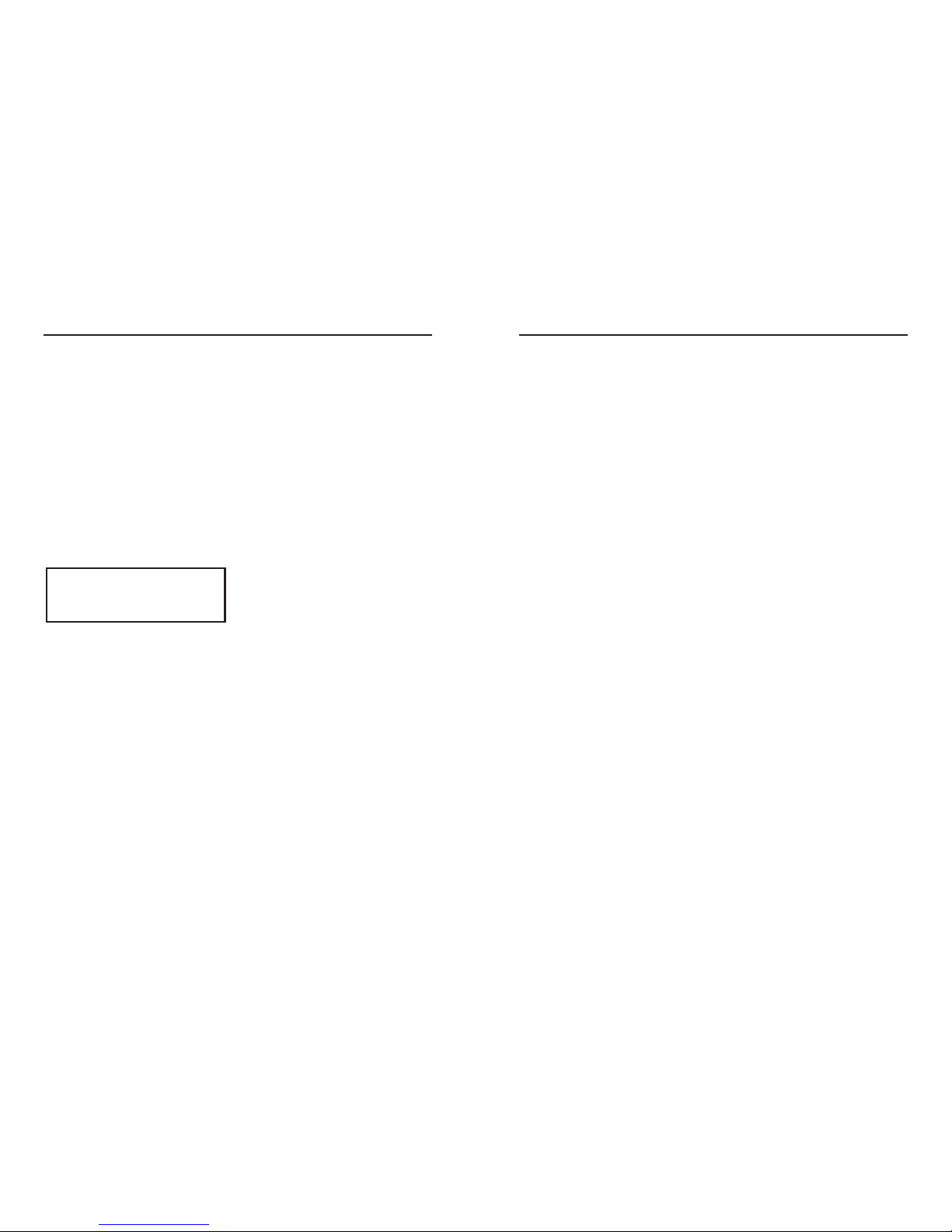

Entering a Password

When an attempt is made to change a restricted setting, a password prompt will appear.

Proceed as follows:

•Use left/right arrow keys to move to each digit.

• Use the up/down arrows to increase/decrease the number.

• Press Enter when complete.

The module is supplied from the factory with the password 0010. However, the password

may be changed if required (see the explanation under “General Settings” below).

Note: Once the password is entered, it remains in effect (allowing access) until exit from the main

menu to the normal monitoring screen, or until there has been no keypad activity for 30 minutes.

Changing a Setting

When the value or selection for a setting has been changed, either:

• Press the Enter button to accept the change.

• Press the Esc button to cancel the change.

General Settings

You gain access to the General settings through the View/Edit Settings Menu, which is on

the main menu (see page 25 for the menu structure).

Date/Time

Use left/right arrow keys to select each digit. Use the up/down arrow keys to

increase/decrease the number.

Units

Use the cursor to select feet, meters, or zones as required. Note: Do not choose zones

unless the system includes only zone sensing cables with zone connectors.

Password:

0000

^

0000...4095

Changing Settings (View/Edit Settings)

22 23

2524

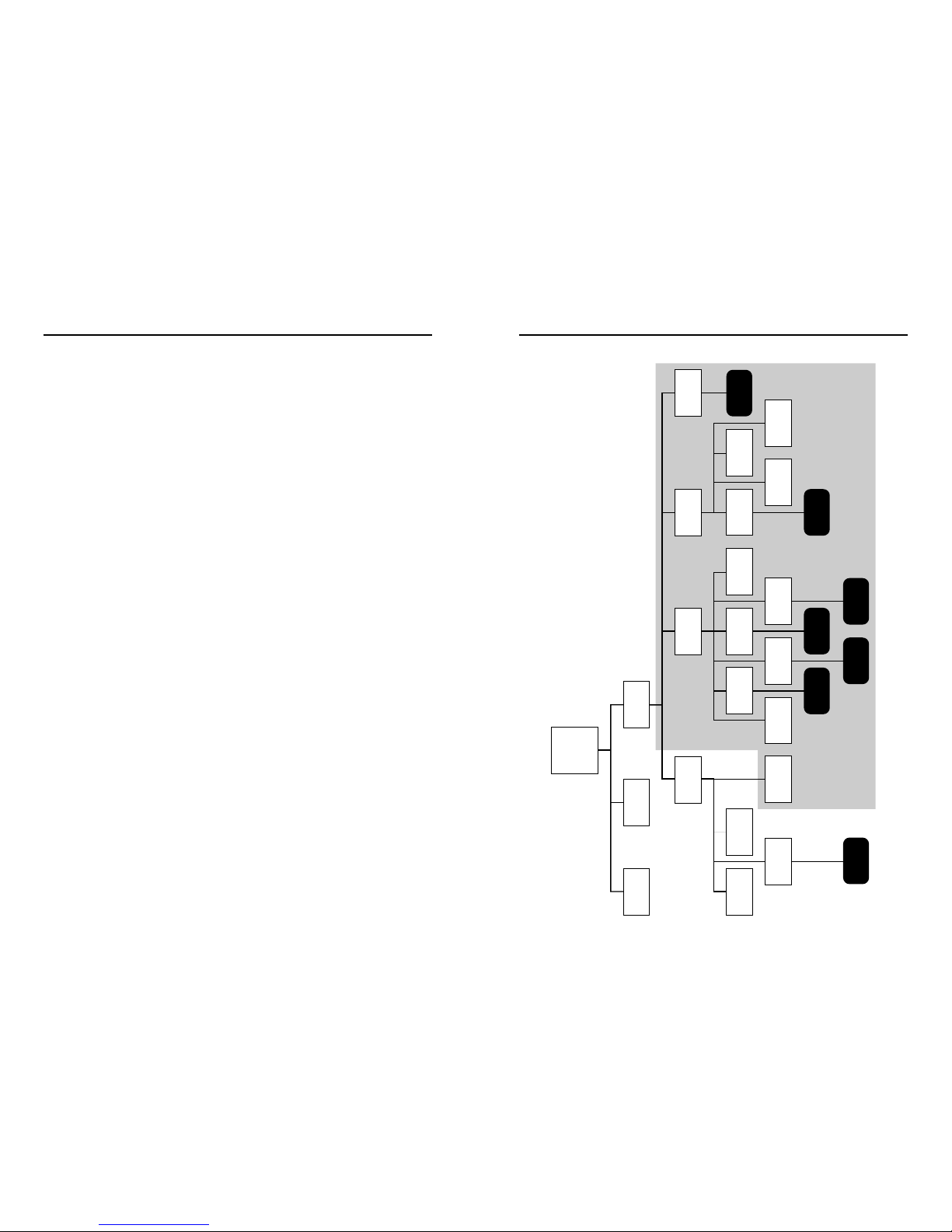

Appendix 1 - Menu Structure

Sensitivity

Select:

• “normal” sensitivity for most applications

• “high” sensitivity for de-ionized water

• “low” sensitivity for particularly active or exposed applications

Barrier Resistance

If you are using a zener barrier (or a lightning protection device) its resistance can be

“dialed out” so the system map can begin at 0.

Note: Always set this value BEFORE mapping the system. Consult your Raychem TraceTek

representative for further details.

Port Settings

You gain access to the Port settings through the View/Edit Settings Menu, which is on the

main menu (see page 25 for the menu structure).

Baud

The serial port can be set to a variety of communications rates. The default is 9600.

Modem

This selects a menu of modem commands. Contact Raychem for additional information.

485 Address

This entry assigns an RS-485 address for the TTDM. This will allow multiple TTDM units

to be networked. Contact Raychem for additional information.

Terminal

This selection provides a real-time display of communications to and from a modem or

host system, which can be helpful for diagnostic purposes.

Self-Test Settings

You gain access to the Self-Test settings through the Self-Test Menu, the last item on the

View/Edit Settings Menu, (see page 25 for the menu structure).

The Self-Test Menu allows individual functions to be tested, and expands on tests per-

formed when the (self) Test key is pressed. The tests available for a function are displayed

after that function is selected from the Self-Test Menu. They include:

• UI test (User Interface) • Keypad

• Memory Tests • Relay Test

• SI test (Sensor Interface) • 4–20 mA Test

• Audio Test • Ext Comm Loop Back Test

• Display Test (for serial port)

General

Time/Date Language

Units Password

Leak Ports Self-Test

Menu

feet

metres

zones

Low

Normal

High

ReAlarmInt AudibleAlarm Barrier Res

Auto ResetReAlrmDist Sensitivity

Select...

485 Address

Modem Terminal

On

Off

Select...

Baud

Select...

On

Off Password required to change settings

Menu

View/Edit

Settings

System

Status

Events

History

SI H/W Error A self-test of the Sensor Interface Hardware has

failed; the unit needs repair.

✓SI H/W Recovered The hardware problem has been corrected.

Service Service Req’d A small amount of current is flowing between

the two sensing wires; this usually indicates

something is contacting the sensing cable that

should be investigated and corrected.

✓Service Clear The condition requiring service has been cleared.

User action {Settings} Changed When a user changes settings, the name of the

setting, the time, and date are recorded in the

Events History log.

Alarm Silenced

Reset

Type of

Event Message Description

Power Power Down The time power was last supplied is stored in

nonvolatile memory, and is entered into the

Events History Log when power is restored.

Restart The Events Log history records when power is

supplied to the unit, or when the unit is manually

restarted.

Leak Leak Liquid detected at the location displayed.

Re-alarm Occurs under three different situations:

•Location changed past re-alarm threshold;

TTDM displays most recent location (without

brackets). This likely means the leak is moving

(or drying).

• New location detected more than 25 ft (8 m)

from original location; TTDM displays most

recent “average” location in square brackets.

This may indicate a new leak, or a new point of

contact with a serpentined cable.

• Automatic re-alarm after the Re-alarm interval

(a user setting) if the leak condition still exists.

✓Leak Cleared Displayed when cable returns to normal after leak.

New Leak A new leak has been detected after an earlier leak

was cleared but not Reset.

Fault Cable Break Loss of continuity in both detection loops; may

be broken or disconnected sensing cable, jumper

cable, leader cable, or connections.

YB Loop Break Break in the Yellow-Black sensing cable loop.

RG Loop Break Break in the Red-Green sensing cable loop.

Loop Imbalance Resistance of the two loops differs by more than

25%; this may indicate the cable has been damaged.

✓Cable Restored Displayed when cable returns to normal after any of

the faults noted above.

SI Comm Error Communications problem between the User Interface

and Sensor Interface boards, which may be due to a

faulty connection or damaged ribbon cable.

✓SI Comm Recovered Communications between UI and SI have

been restored.

Appendix 2 - Events Glossary

26 27

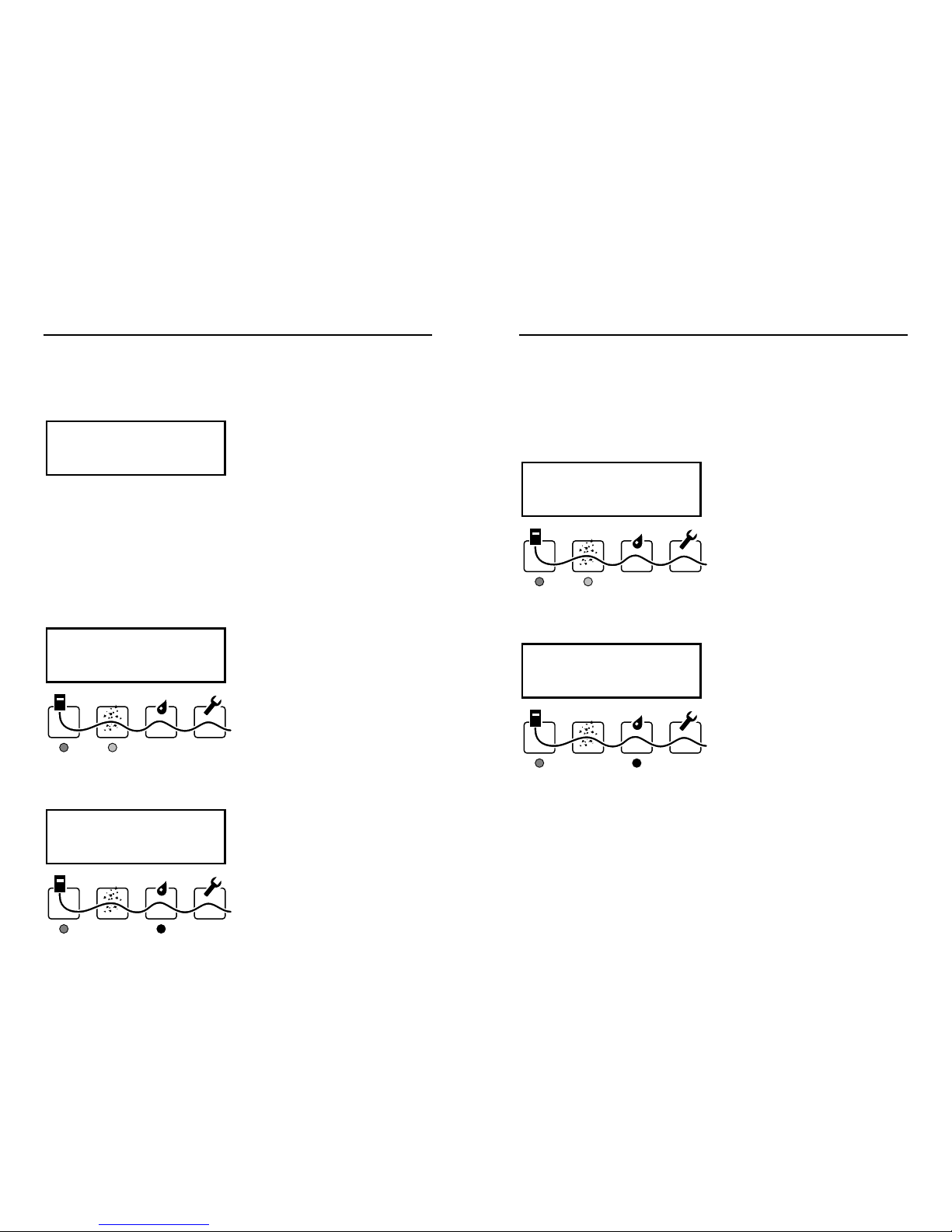

Investigating Leaks and Faults

If the location of a leak is not apparent, it is often useful to subdivide the leak detection

circuit, as illustrated below. To accomplish this, it is best to have a TraceTek Portable Test

Box (PTB) and an extra Modular End Termination. Contact your local TraceTek represen-

tative to obtain these products. Note that the PTB comes with instructions on its use.

To segment the system and isolate problems, find a TraceTek connection at a convenient

point somewhere at the center of the detection circuit. You can then use a PTB to check

one portion of the system (to verify circuit integrity, to detect the presence of liquid, and

even to determine its location). If you install an end termination on the other length of

cable (going back to the TTDM Alarm and Locating Module), you can use the TTDM to

check the “front half” of the sensing circuit.

You can further subdivide the circuit, and even test individual lengths of cables, as shown

in the third diagram below. Even the most perplexing problems can usually be isolated

and resolved using this methodical approach.

28 29

Cleaning the Module

To clean the outside surface, use a damp cloth or sponge. Do not use solvents or abrasive

cleaners, and do not open the enclosure while it is wet (it is an electrical device).

Fuse Replacement

The fuse on the power supply board (12 on foldout) is a 200-mA, 250-V, quick-acting

microfuse. It has an F1 rating, characteristic code F (quick-acting). Use no other type of

fuse or the TTDM could be damaged or could fail to perform properly.

Routine Maintenance

It is recommended that the TraceTek system be thoroughly checked twice a year. Such a

check will identify conditions that adversely affect the leak-locating capability of the sys-

tem. More frequent checks may be required if the sensing cable is repeatedly exposed to

leaks, or if construction or repair work is done where the sensing cable may be exposed.

Contact your local Raychem TraceTek representative for further information on service

support.

Storage and Handling of Sensing Cable

Despite their rugged construction, TraceTek sensing cables must be handled in a manner

appropriate for a sensing device or they may be damaged and require replacement.

Therefore, you should follow some basic rules for storing and handling all TraceTek

sensing cables:

• Store spare cable in its original container in a clean, dry place until ready

for installation.

• Schedule cable installation after all mechanical, plumbing, and electrical work has

been completed.

• Clean the area where the cable is to be installed, and remove any obvious debris or

other sources of contamination.

• Do not solder or weld near the cable without providing protection from heat, solder flux,

or weld splatter.

• Do not drop tools or floor tile on the cable; sharp and heavy objects may damage

the cable.

• Avoid walking or stepping on the cable. Provide shielding (for example, a half shell of

plastic pipe) where additional protection is necessary.

• Do not use tape to secure sensing cable (some tapes and adhesives absorb moisture)

or use solvents that could eventually cause an alarm.

• Do not drag sensing cable through contaminants (such as pipe dope, PVC cement,

solvents, oil, or dirt).

Appendix 3 - Maintenance

TTDM

Alarm and

Locating Module

End termination

End termination

End termination

End termination

PTB

PTB

To confirm that the scale is acceptable, use the “Leak” option in the 4–20 mA Test menu.

Simulate leaks at various locations, and verify that the output is as expected with the

equipment or instrument connected to the TTDM 4–20 output port.

Note: The maximum current output can be calibrated using trimpot R7 on the 4–20 mA

circuit board (8 on foldout).

Serial Port

The external communications port is configured for use as either RS-232 or RS-485. The

factory default is RS-232 full-duplex with no hardware handshaking.

This is suitable for connection to a remote host PC, laptop, serial printer, or modem. With

the appropriate cable and standard terminal software, a PC can receive time, communica-

tions, and Events History data.

One of the simplest but most important uses of the serial port is obtaining a printout of

the Events History log with a serial printer, or a PC with communications software.

Contact your Raychem TraceTek representative for additional information to assist in con-

necting and configuring for serial port communications.

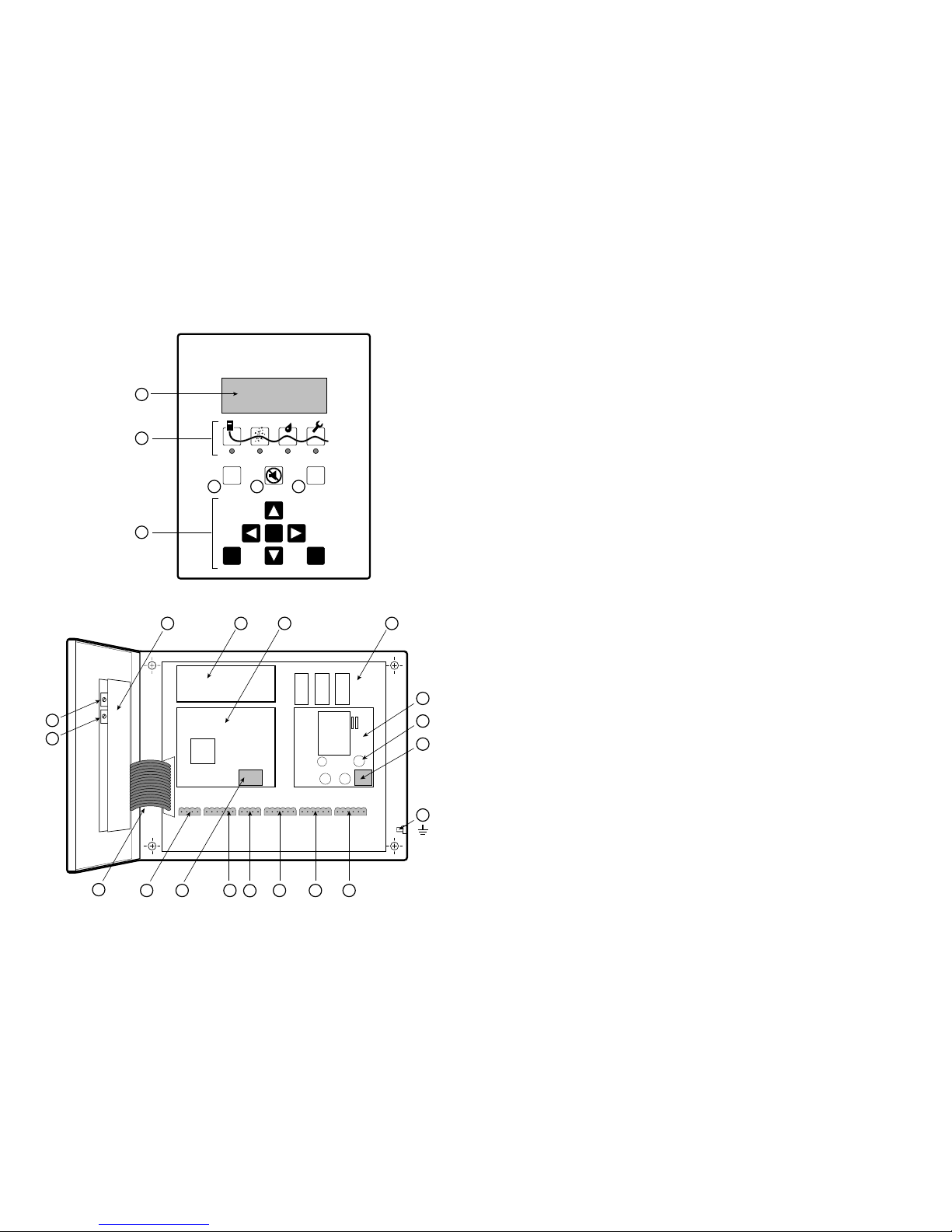

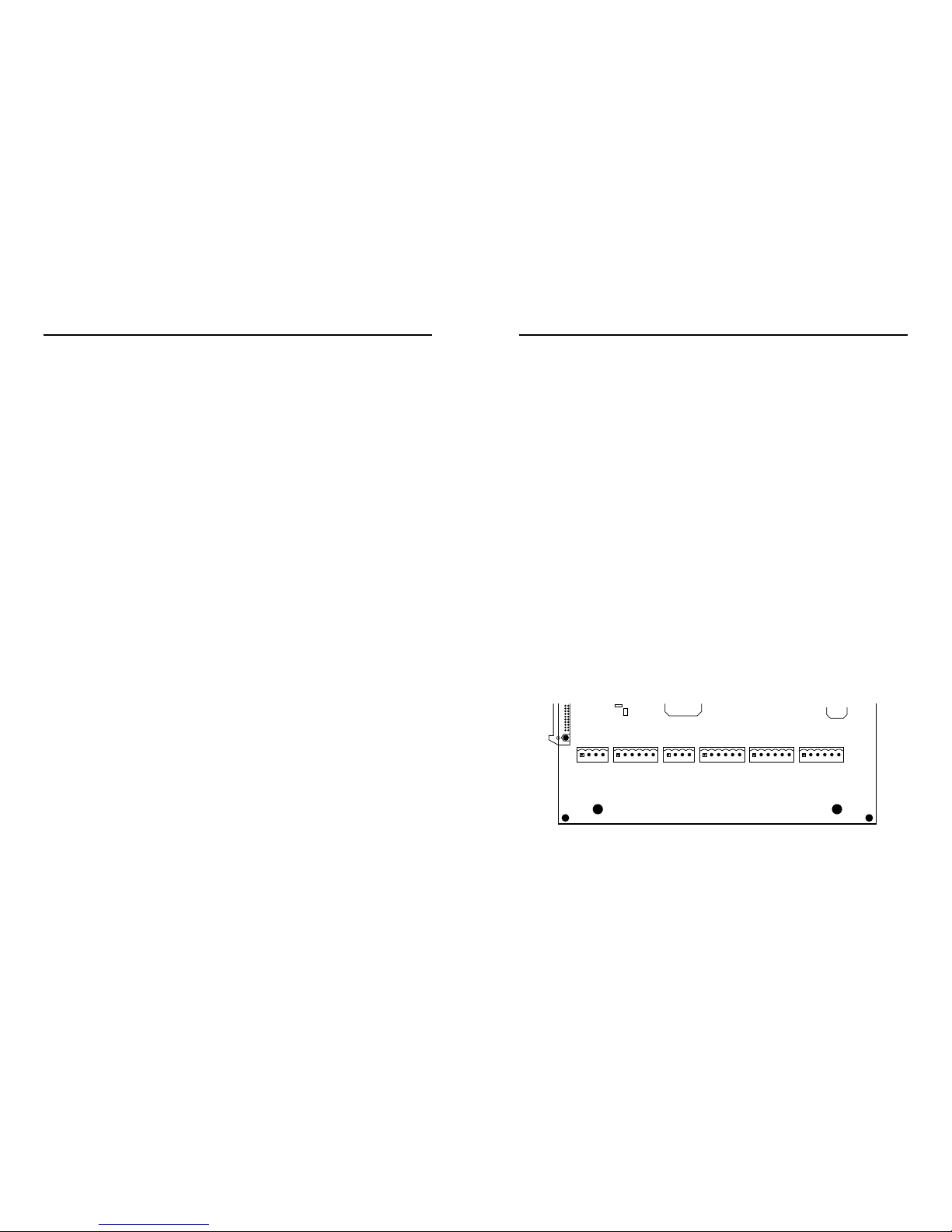

Connection Details

The illustration below shows the pinouts/terminals for the alarm relays, 4–20 mA port,

and RS-232/485 serial port. (labeled EXT COM PORT on the motherboard)

+51SO

1

PL

RS-485 EXT XMTRS

J10

PL

RS-232/485 EXT COM PORT

J13

PL

4-20MA OUT PORT

J2

SERVICE RELAY

5A 250V

J6

ALARM RELAY

5A 250V

J25

TROUBLE RELAY

5A 250V

J9

1 1 1 1 1

ICOM485+ 485–

1

2

3

4

RX/A TX/B RTS CTS +5V GND

5

6

7

8

9

10

IRTN IOUT +V +VRTN

11

12

13

14

NC NO COM NC NO COM

15

16

17

18

19

20

NC NO COM NC NO COM

21

22

23

24

25

26

NC NO COM NC NO COM

27

28

29

30

31

32

4–20 mA Current Transmitter

The TTDM adjusts its 4–20 mA output based on the leak detection status as detailed below.

Fault conditions:

Output (mA) Description

0 Electronic fault or loss of power

1.00 Fault—communications between SI and UI boards

2.00 Fault—cable break

3.00 Fault—cable damage (loop imbalance)

3.50 Service Required alarm

Normal conditions and leaks:

4.00 System normal

5.00 - 20.00 Leak; value scaled to indicate location of leak

Testing

When external equipment is connected to the TTDM 4–20 mA output port, the current

loop can be tested using the “4–20 mA Test” series under the Self-Test Menu. Before

doing so, confirm that all connections have been made, including 24 Vdc to TTDM

terminals 13 and 14. To conduct the 4–20 port tests, make the following menu selections,

beginning from the Main Menu: “View/Edit Settings,” “Self-Test Menu,” “4–20 mA Test.”

The entries in the 4–20 mA Test Menu are:

Electronics Fault

SI Comm Error

Cable Break

Loop Imbalance

Service Req’d

System Normal

Leak (a submenu prompts for a location to simulate)

20 mA Val

All but the last entry simulate the conditions noted; the TTDM changes its current output to that

designated for the condition selected (for example, 3.50 mA for a Service Required alarm).

Adjusting the Scale

Default value for the upper bound (i.e. the location that would result in the maximum cur-

rent output of 20 mA) is 5000 ft. (1500 m). To change the scale, select “20 mA Val” at the

bottom of the “4–20 mA Test” menu. Then enter a new upper bound to provide a reasonable

scale for your system.

Important: The upper bound must be greater than the Test Length (which the TTDM

displays in the System Status screen).

30 31

Appendix 4 - Interface Details

TTDM Operation Diagram

The TTDM measures resistance of

each circuit loop independently to

ensure the integrity of the circuit.

The resistance of the yellow-black

loop is used to compute the “Test

Length” displayed in the System

Status screen; it is based on a

real-time measurement.

The TTDM measures current

“leakage” between the two sensing

loops. When a leak is present, the

TTDM limits the current to 270

microamps, and measures the

voltage difference between the

yellow and black wires. The resis-

tance along the black sensing wire

to the leak is determined by a

simple application of Ohm’s law

(R = V/I). The resistance per unit

length of the sensing wire is tightly

controlled in manufacturing, so

this location is easily computed.

33

Appendix 6 - TraceTek Technical Data

RRG RYB

End

termination

End

termination

Loop resistances and test length

Sensing

cable

TTDM

DVLeak DVLocation

Leak current, resistance, location

Sensing

cable

TTDM Current

RLocation

RS-to-S

Red Green Yellow Black

Red Green Yellow Black

Relay wiring options

The illustrations below show how relays (15, 16, and 17 on foldout) can be jumpered

together to allow remote monitoring of the TTDM status with only a single pair of wires.

The TTDM

de-energizes

its relays to signal an alarm condition. Therefore, loss of power

as well as any other type of alarm would trip the remote alarm.

Alarm on open circuit

Alarm on closed circuit

SERVICE RELAY

5A 250V

J6

LEAK RELAY

5A 250V

J25

FAULT RELAY

5A 250V

J9

1 1 1

NC NO COM NC NO COM

15

16

17

18

19

20

NC NO COM NC NO COM

21

22

23

24

25

26

NC NO COM NC NO COM

27

28

29

30

31

32

Monitoring circuit

(alarm on closed circuit)

Relays wired

in parallel

SERVICE RELAY

5A 250V

J6

LEAK RELAY

5A 250V

J25

FAULT RELAY

5A 250V

J9

1 1 1

NC NO COM NC NO COM

15

16

17

18

19

20

NC NO COM NC NO COM

21

22

23

24

25

26

NC NO COM NC NO COM

27

28

29

30

31

32

Monitoring circuit

(alarm on open circuit)

Relays wired

in series

32

Appendix 5 - Wiring Details

This manual suits for next models

2

Table of contents

Other Raychem Control Unit manuals

Popular Control Unit manuals by other brands

Quectel

Quectel RM502Q-GL Hardware design

Burkert

Burkert 8791 REV.2 operating instructions

M-system

M-system R30CT4E instruction manual

Whelen Engineering Company

Whelen Engineering Company WPA Series installation guide

E-T-A

E-T-A ControlPlex EM12D-TIO user manual

Applied Motion Products

Applied Motion Products ST10-S Hardware manual