Wuhan Raycus Fiber Laser Technologies Co., Ltd.

Users Guide RFL-P500H

TABLE OF CONTENTS

1 Safety Information .....................................................................................................................1

1.1 Security Warning...............................................................................................................1

1.2 Laser Safety Grade............................................................................................................1

1.3 Safety Identification..........................................................................................................2

1.4 Optical Safety....................................................................................................................3

1.5 Electrical Safety ................................................................................................................3

1.6 Other Safety Rules ............................................................................................................3

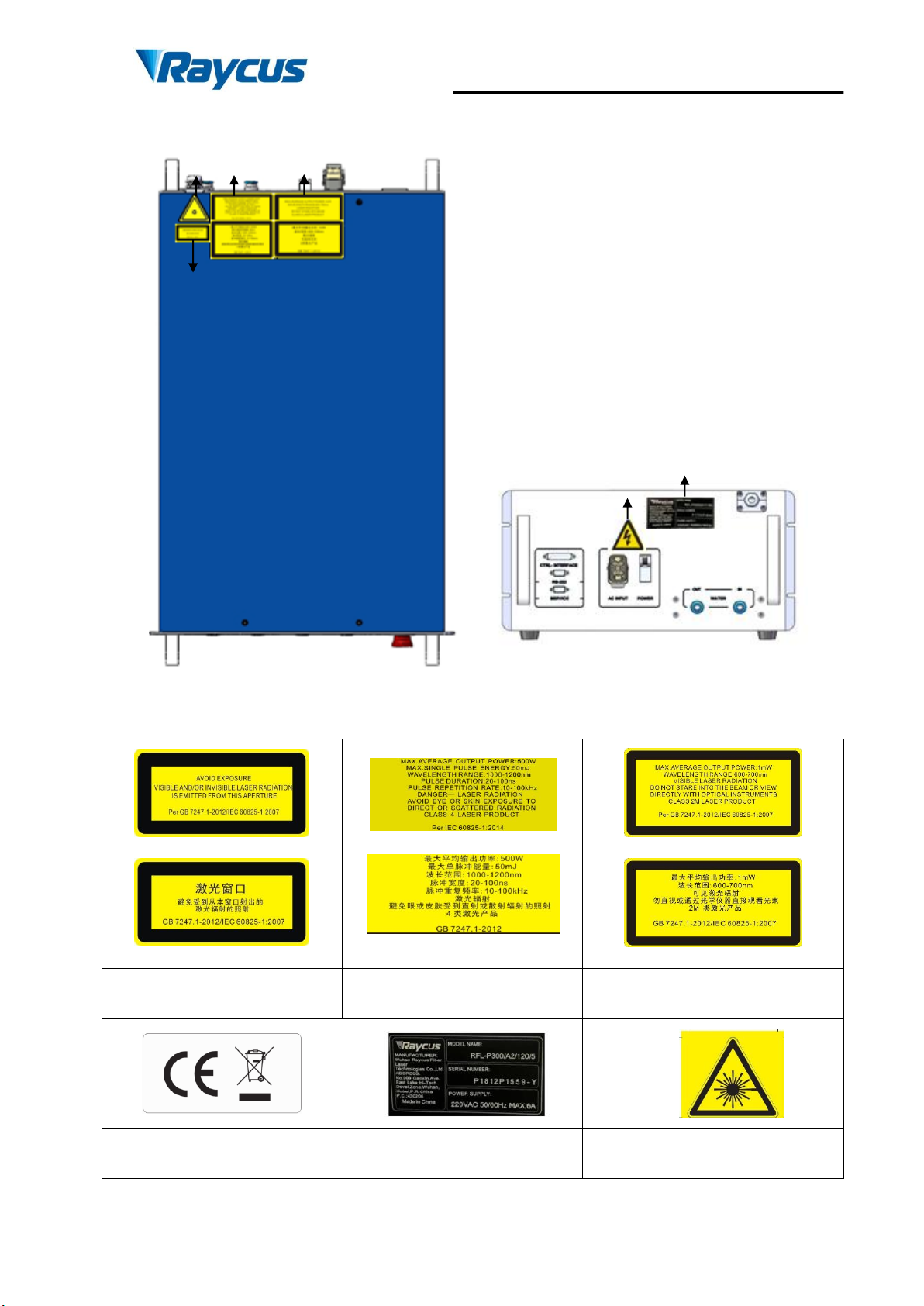

2 Product Description ...................................................................................................................4

2.1 Features .............................................................................................................................4

2.2 Package Parts.....................................................................................................................4

2.3 Unpacking and Inspection.................................................................................................4

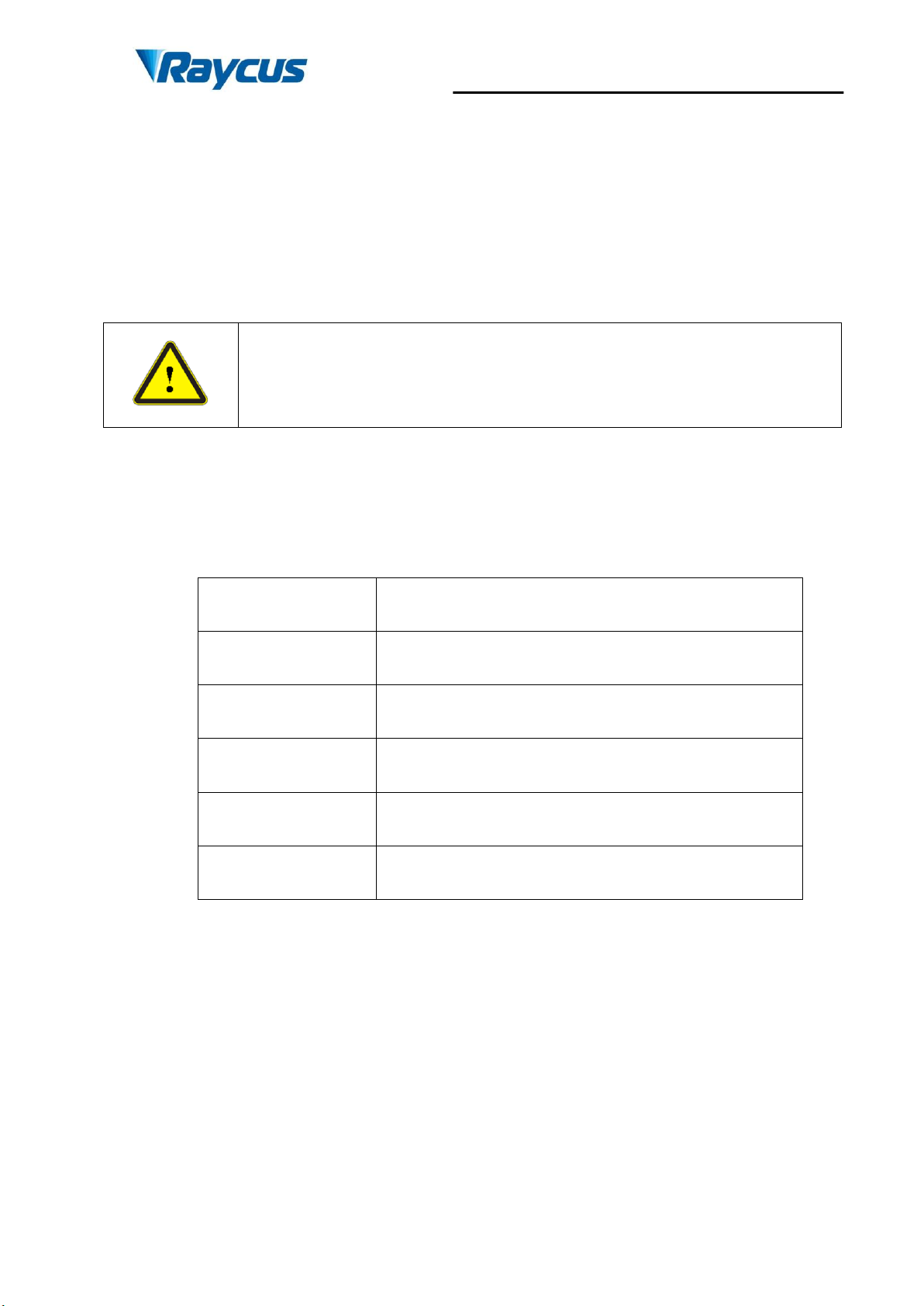

2.4 Operation Environment.....................................................................................................5

2.5 Attentions..........................................................................................................................6

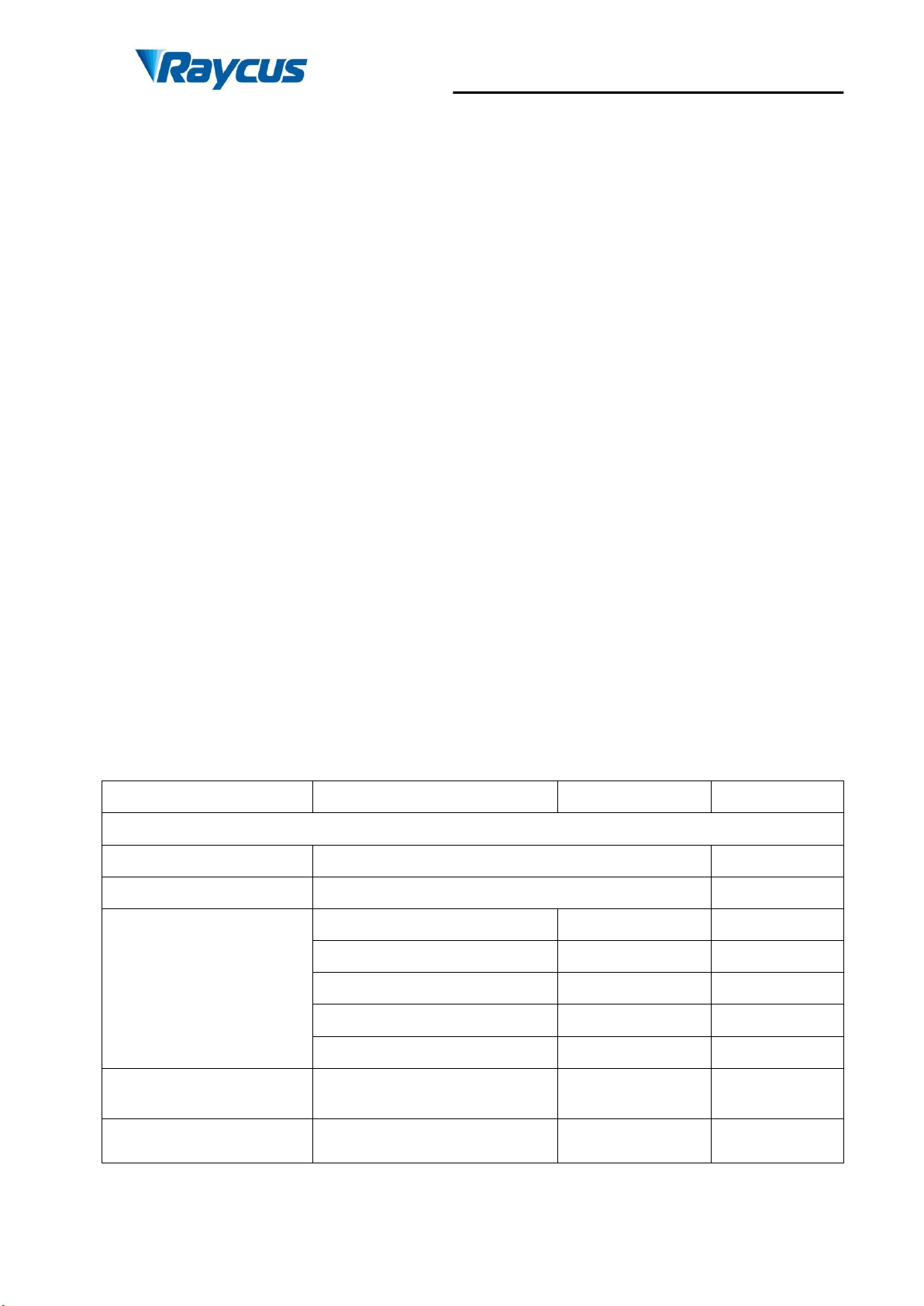

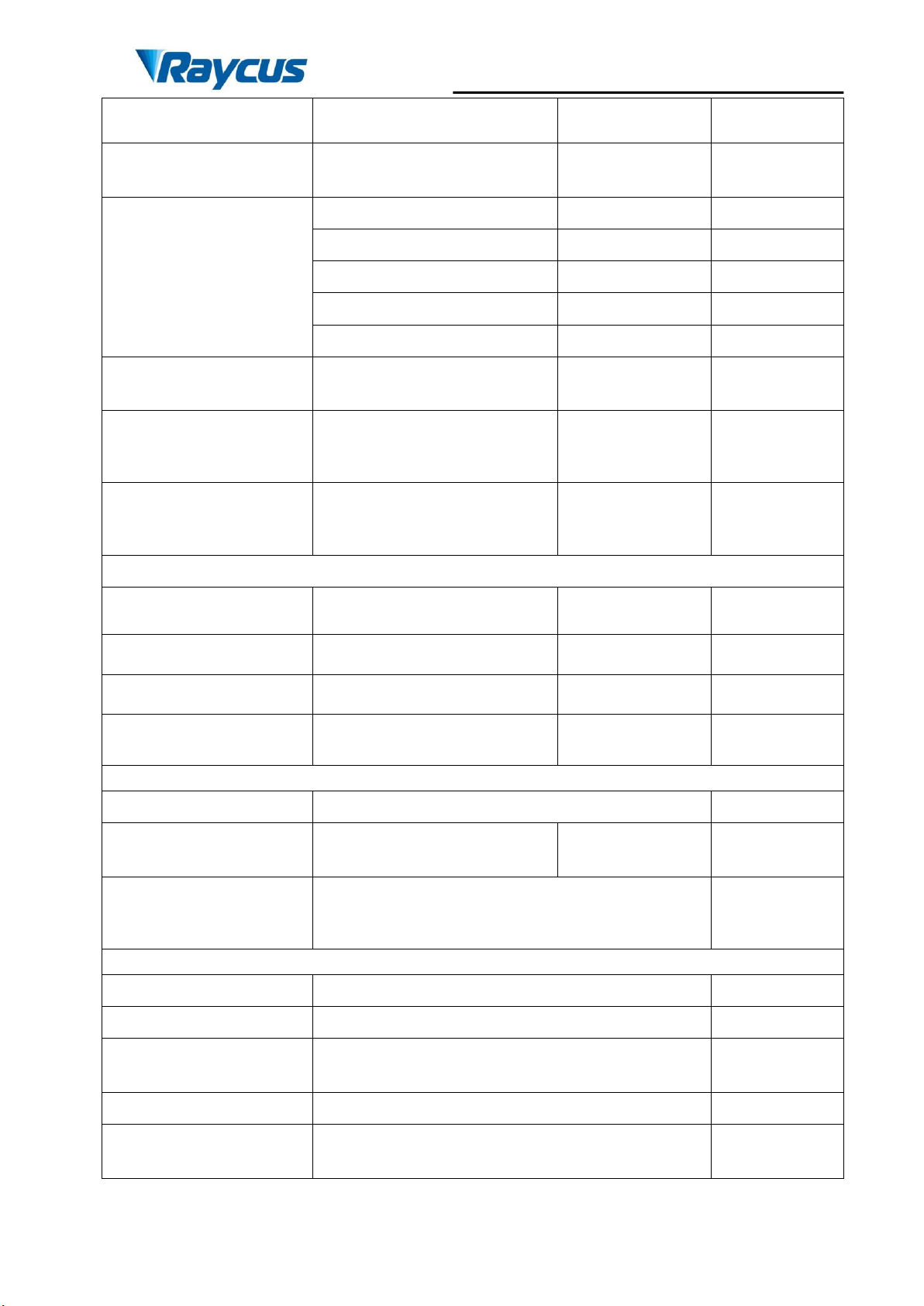

2.6 Specifications ....................................................................................................................6

3 Installation ..................................................................................................................................8

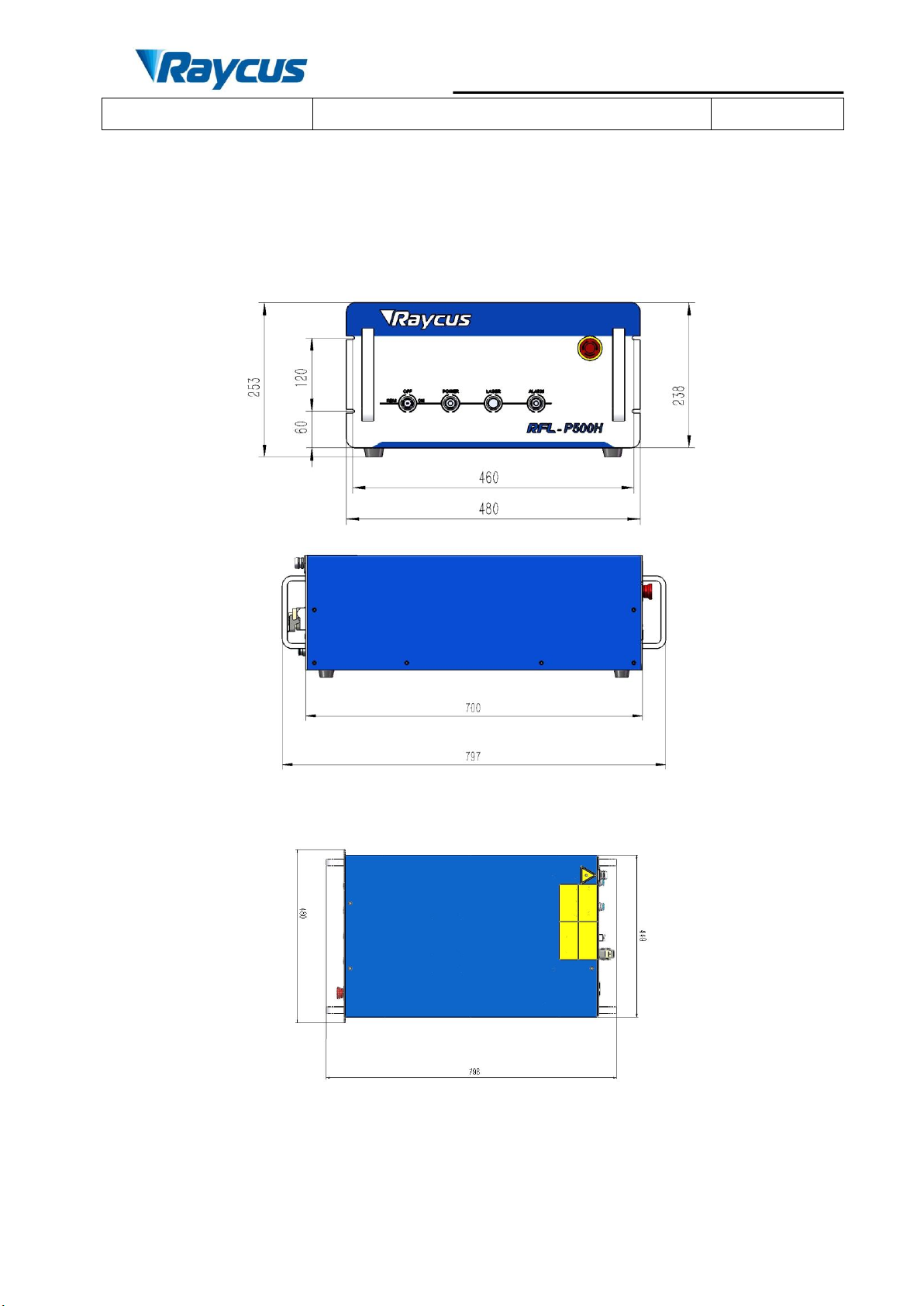

3.1 Dimensions........................................................................................................................8

3.2 Cooling Requirements.......................................................................................................9

3.3 Installation rule................................................................................................................10

4 Using the Product.....................................................................................................................12

4.1 Front Panel ......................................................................................................................12

4.2 Rear Panel .......................................................................................................................13

4.3 Power Connection...........................................................................................................14

4.4 Interface Definitions........................................................................................................15

4.4.1 SERVICE.....................................................................................................................15

4.4.2 Control Interface ..........................................................................................................15

4.4.3 RS-232 Serial Port........................................................................................................21

4.5 Application Steps of Laser Device..................................................................................22

4.5.1 Pre-inspection...............................................................................................................22

4.5.2 Operational Steps .........................................................................................................23

4.5.3 Attention in the process of operation ...........................................................................23

5 Common Alarms and solutions...............................................................................................23

6 Warranty, Return and Maintenance......................................................................................24

6.1 General Warranty............................................................................................................24

6.2 Limitations of Warranty..................................................................................................25

6.3 Service and Repair ..........................................................................................................25