Wuhan Raycus Fiber Laser Technologies Co., Ltd.

User Guide of RFL-C8000S

2

TABLE OF CONTENTS

1 Safety Information......................................................................................................................3

1.1 Symbols Used in this User Guide......................................................................................3

1.2 Laser Classification........................................................................................................... 3

1.3 Safety Labels..................................................................................................................... 4

1.4 Optical Safety.................................................................................................................... 5

1.5 Electrical Safety.................................................................................................................5

1.6 Other Safety Rules.............................................................................................................5

2 Product Description....................................................................................................................6

2.1 Features..............................................................................................................................6

2.2 Package Contents...............................................................................................................6

2.3 Unpacking and Inspection................................................................................................. 6

2.4 Operation Environment..................................................................................................... 7

2.5 Precautions for Use............................................................................................................8

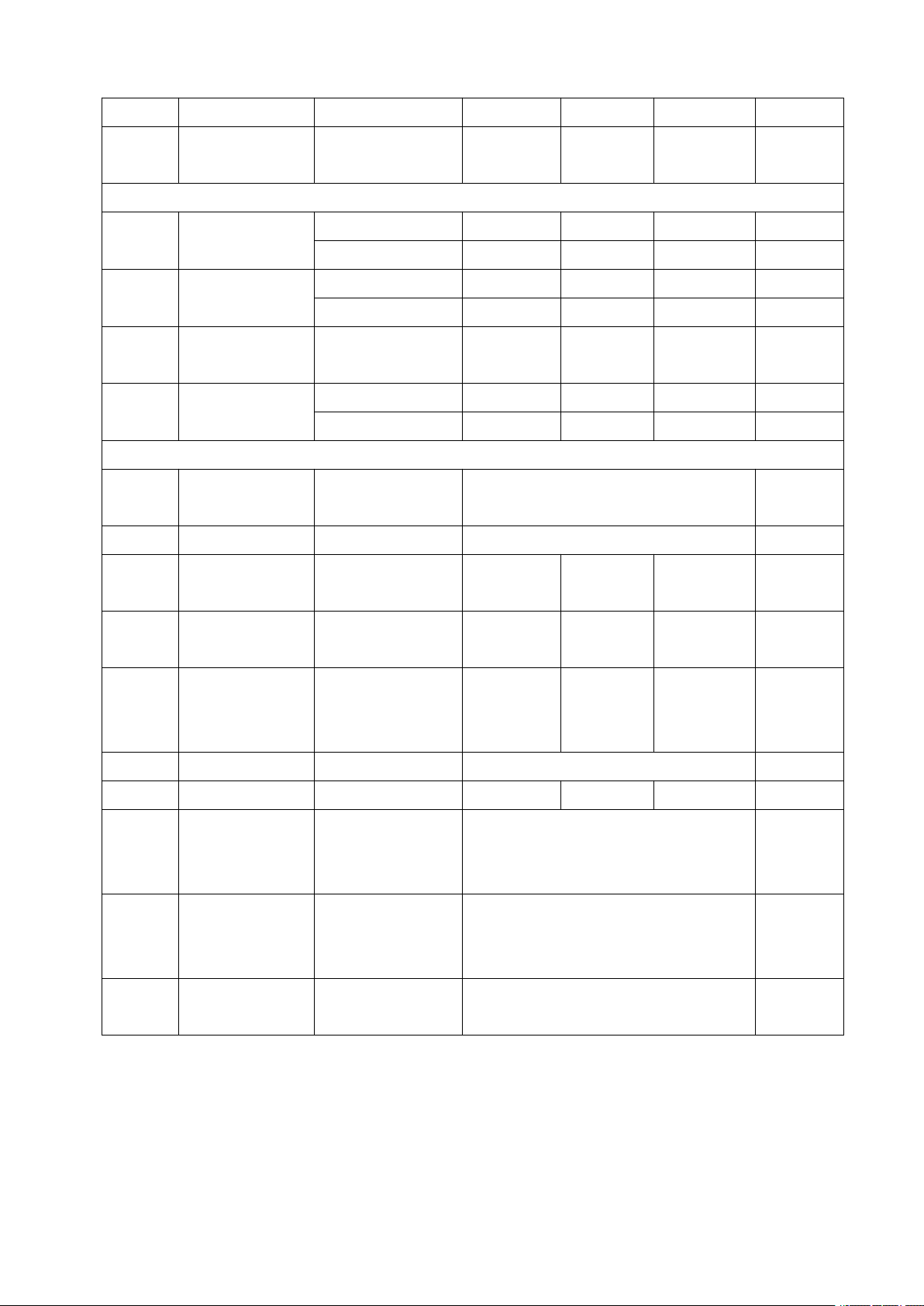

2.6 Specifications.....................................................................................................................9

3 Installation.................................................................................................................................11

3.1 Dimensions...................................................................................................................... 11

3.2 Output Head and Installation........................................................................................... 12

3.3 Cooling Requirements..................................................................................................... 12

3.4 Installation Procedure...................................................................................................... 15

4 Using the Product..................................................................................................................... 17

4.1 Front Panel.......................................................................................................................17

4.2 Rear Panel........................................................................................................................18

4.3 Power Connection............................................................................................................19

4.4 Interface Definitions........................................................................................................ 20

4.5 Steps of Installation......................................................................................................... 24

4.6 Steps of Starting...............................................................................................................24

4.7 Functions of the clientware..............................................................................................24

4.8 Control Modes................................................................................................................. 34

4.9 Guide laser control...........................................................................................................38

4.10 The Programming Mode (Waveform Editing).............................................................. 38

4.11 Laser timing diagram.....................................................................................................46

4.12 Modulation signal requirements.................................................................................... 47

4.13 Steps of shutting down.................................................................................................. 47

5 Alarms and Solutions............................................................................................................... 48

5.1 Alarms Display................................................................................................................ 48

5.2 Alarm solutions................................................................................................................48

6 Warranty, Return and Maintenance...................................................................................... 50

6.1 General Warranty.............................................................................................................50

6.2 Limitations of Warranty.................................................................................................. 51

6.3 Service and Repair...........................................................................................................51