Raypak Xtherm 1505 User manual

Other Raypak Swimming Pool Heater manuals

Raypak

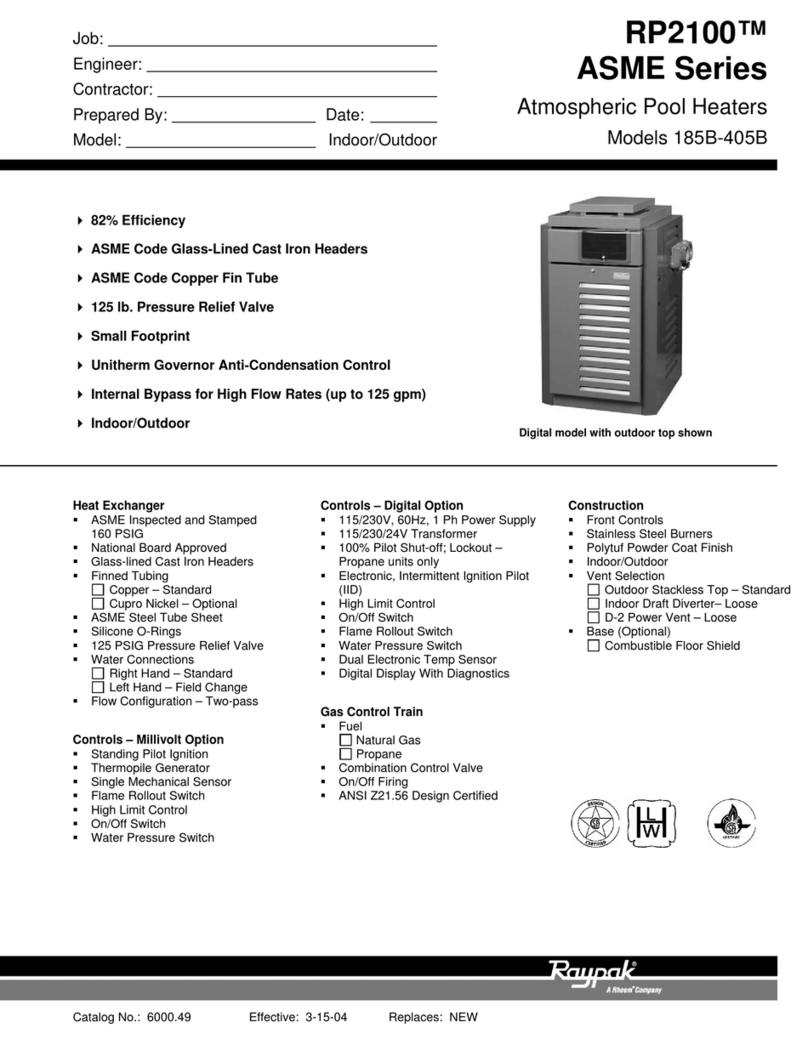

Raypak RP2100 ASME R185B User manual

Raypak

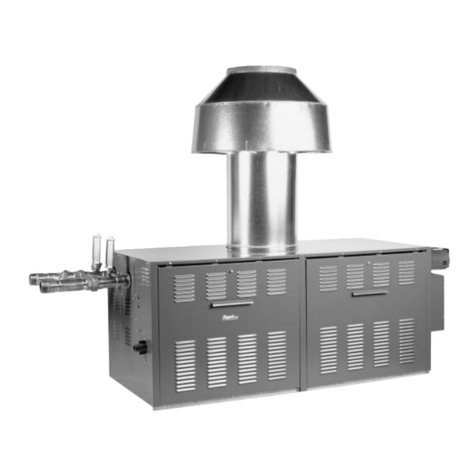

Raypak raytherm P-1223 User manual

Raypak

Raypak RP2100 ASME R185B User manual

Raypak

Raypak ELS 1102-2 Setup guide

Raypak

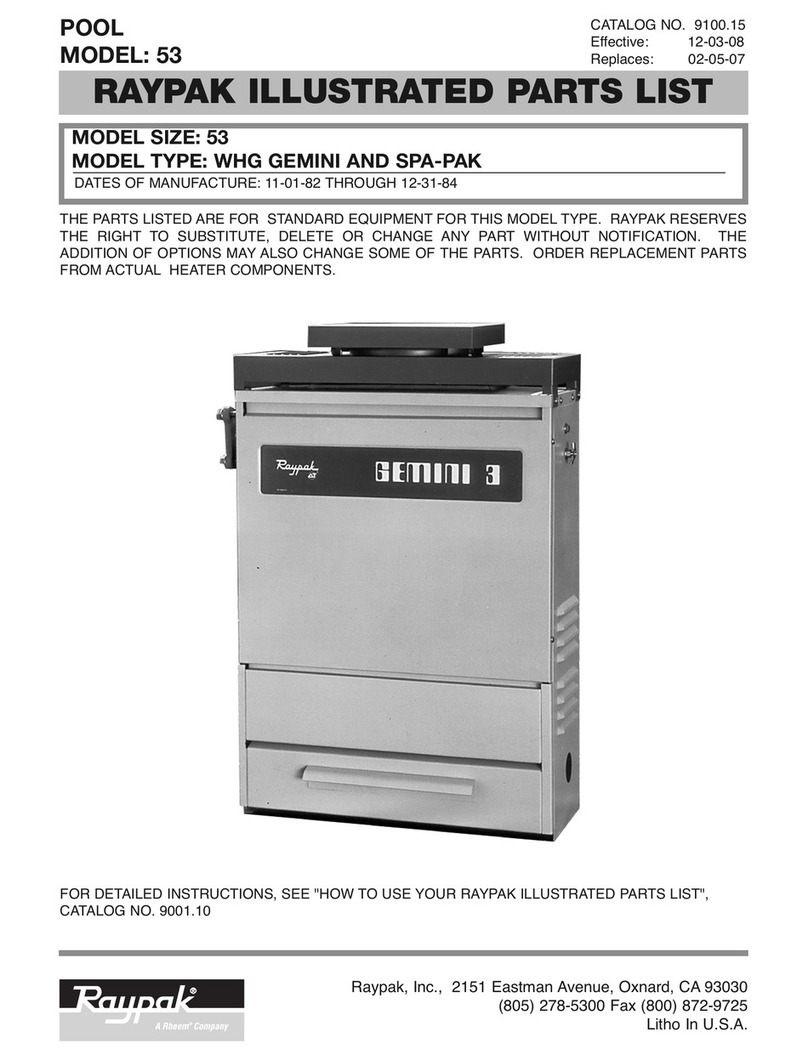

Raypak Gemini 53 Setup guide

Raypak

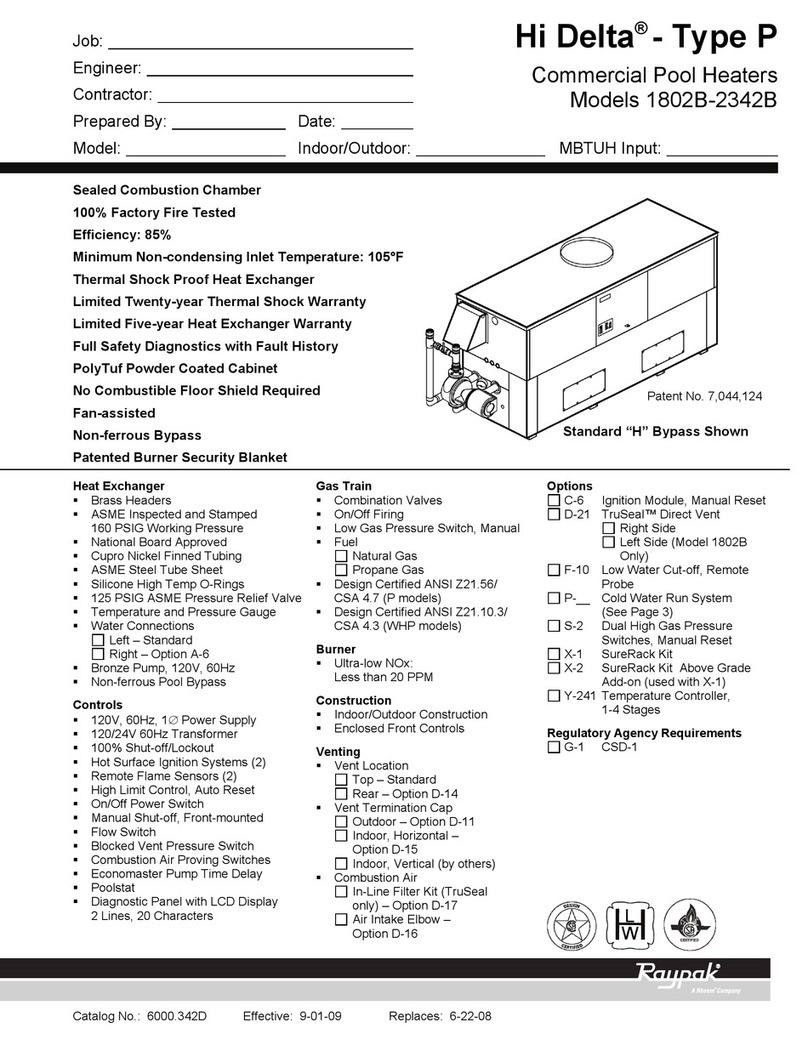

Raypak HI DELTA 1802B User manual

Raypak

Raypak 402 User manual

Raypak

Raypak RAYTHERM P-926 User manual

Raypak

Raypak X94 Manual

Raypak

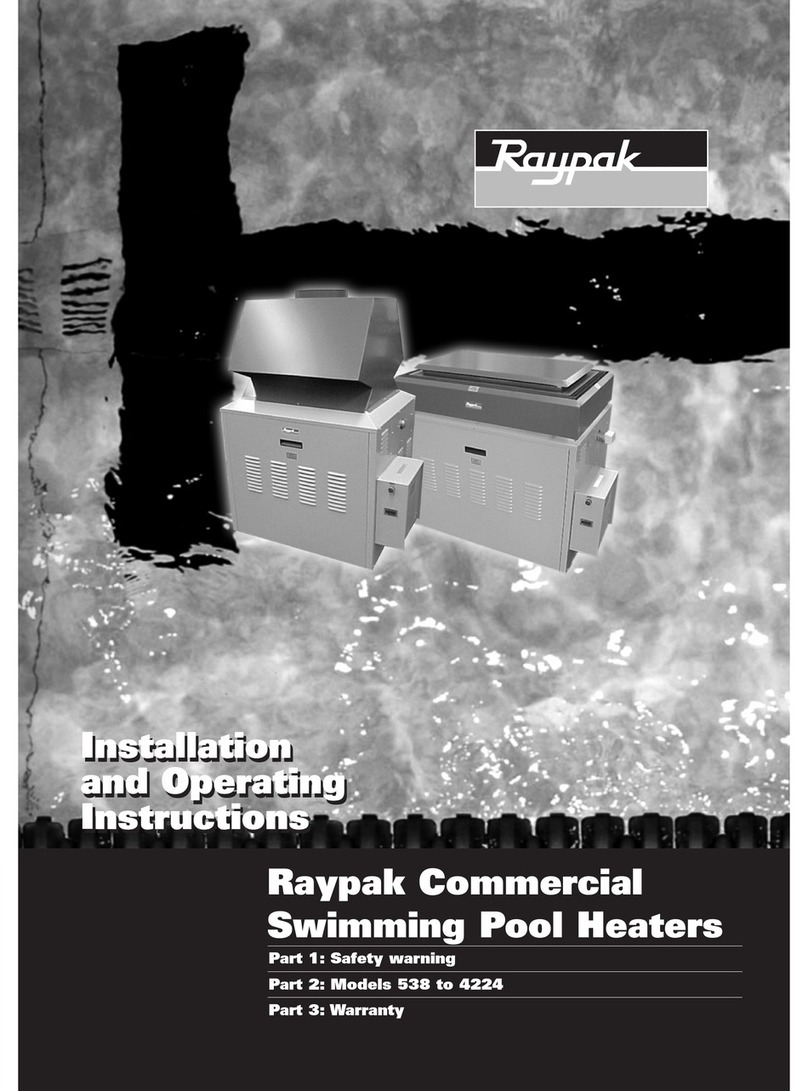

Raypak 538 To 4224 User manual

Raypak

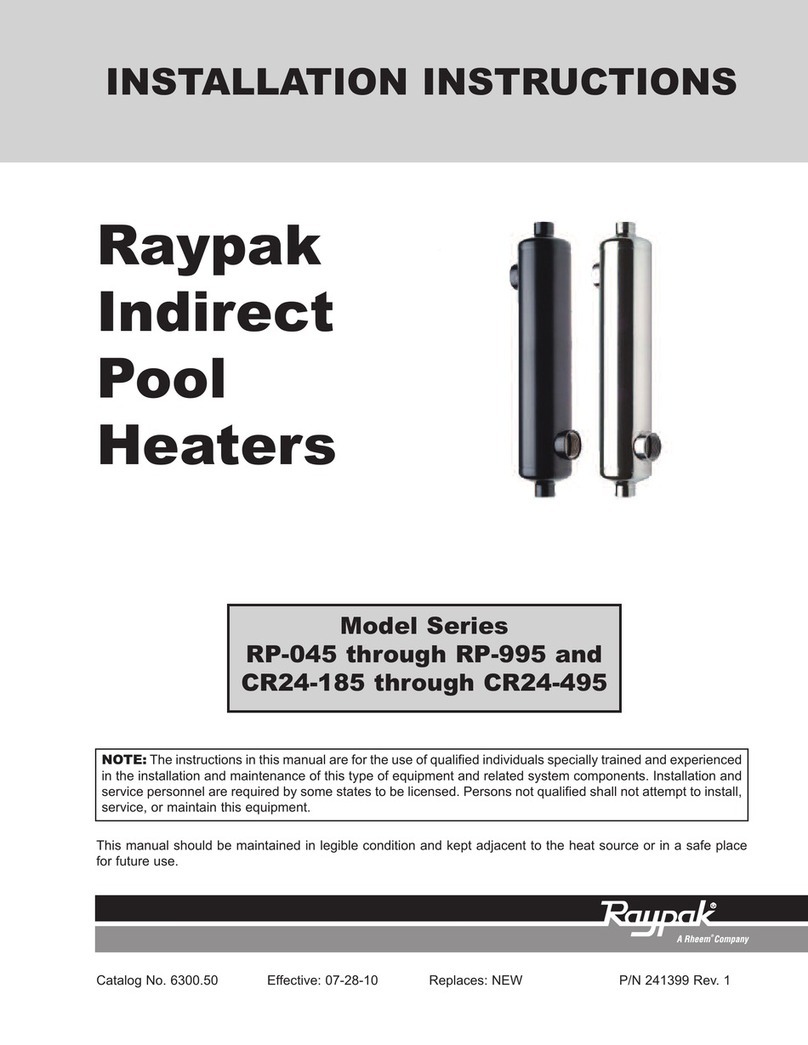

Raypak RP-045 User manual

Raypak

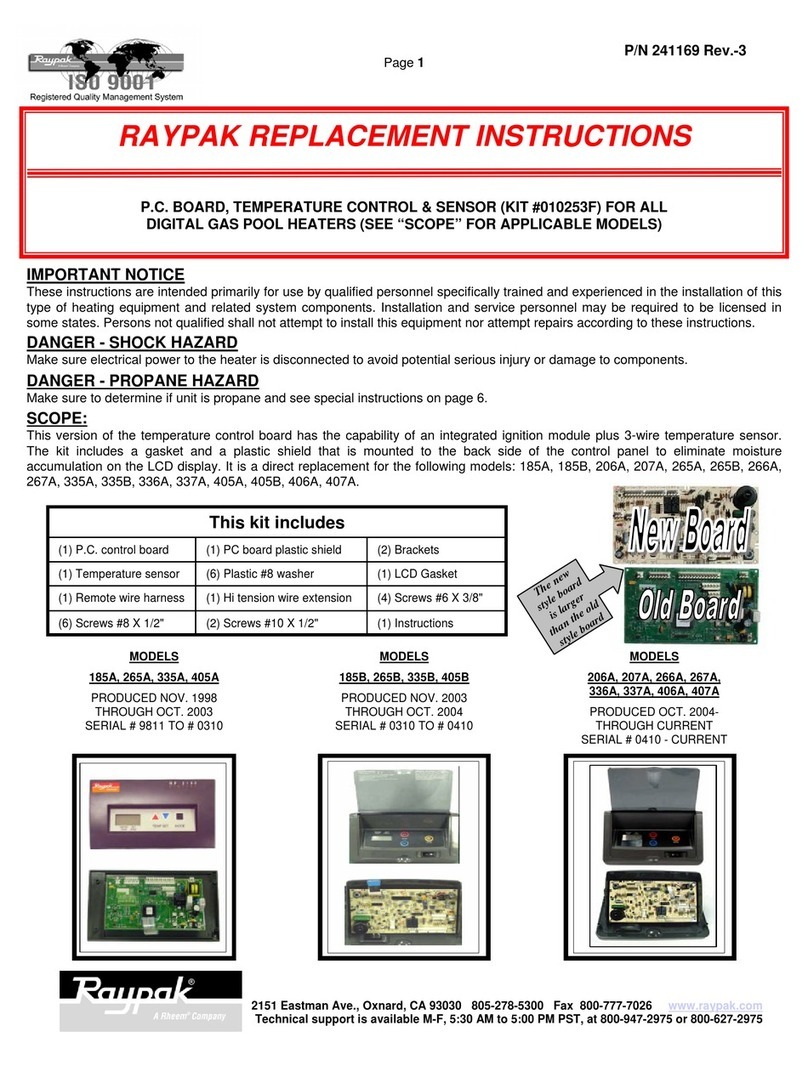

Raypak 185A Guide

Raypak

Raypak 053A User manual

Raypak

Raypak ECONOPAK 203A User manual

Raypak

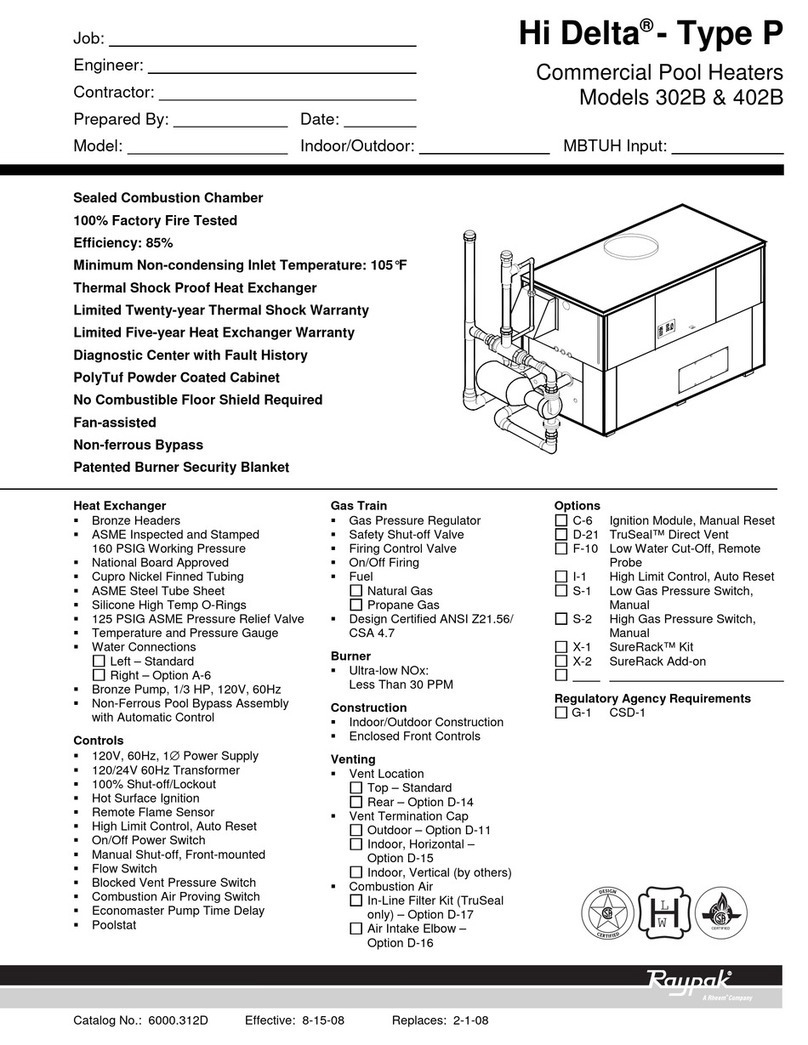

Raypak HI DELTA 302B User manual

Raypak

Raypak HI DELTA 2002B User manual

Raypak

Raypak 180A User manual

Raypak

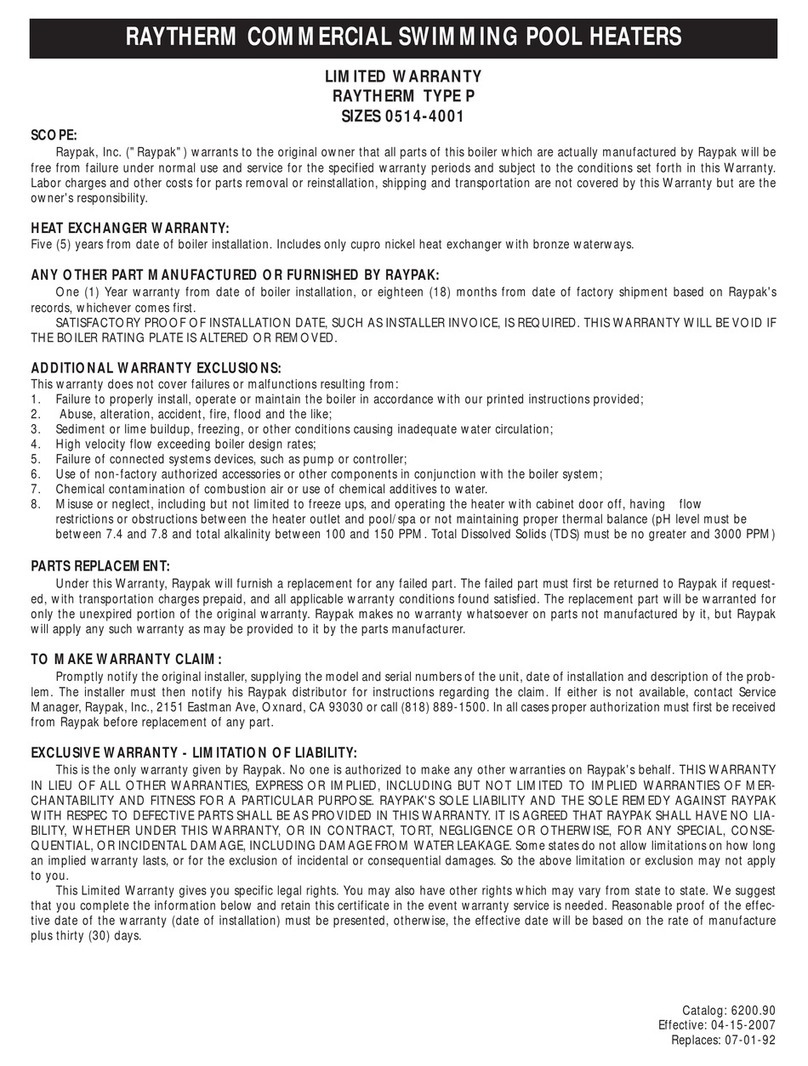

Raypak 6200.90 Use and maintenance manual

Raypak

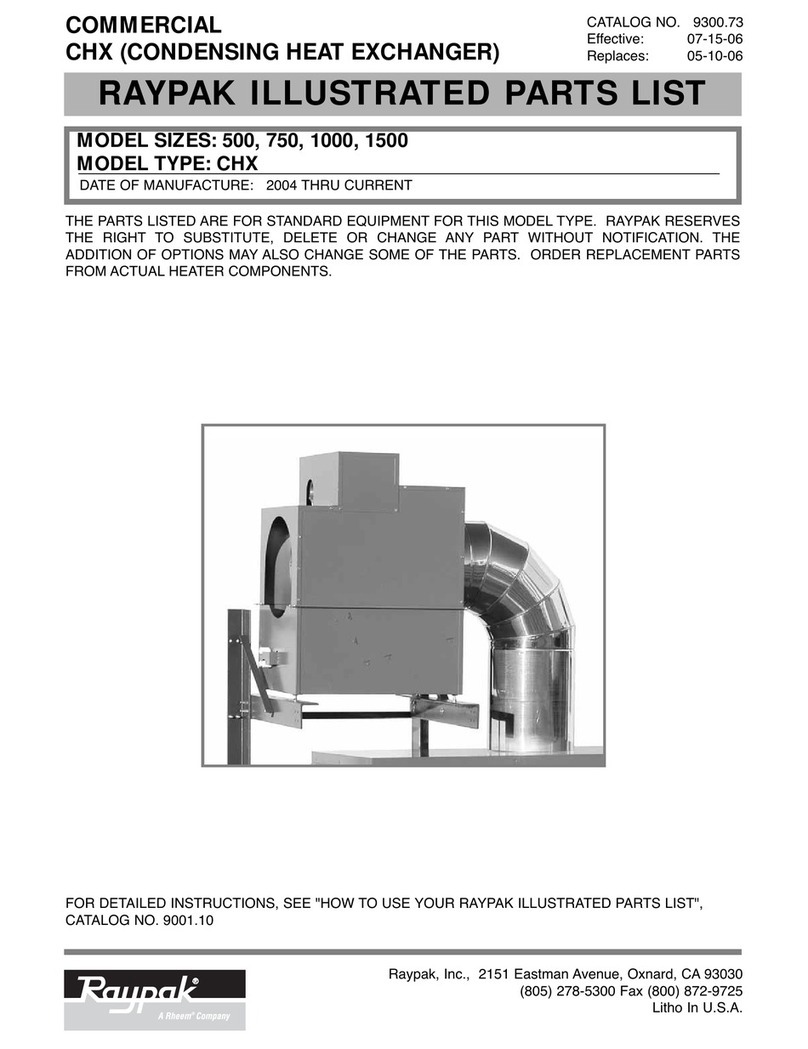

Raypak CHX Setup guide

Raypak

Raypak Versa 105B Brass User manual

Popular Swimming Pool Heater manuals by other brands

Pentair Pool Products

Pentair Pool Products MiniMax CH 150 Operation & installation manual

Jandy

Jandy LJ Installation and operation manual

Pentair Pool Products

Pentair Pool Products MiniMax NT Series Operation & installation manual

Hayward Pool Products

Hayward Pool Products HP40A Installation instructions manual

Laars

Laars Lite 2 LC Installation and operation manual

SUPREME

SUPREME Heatseeker Solar Pool Heating user guide

UTC

UTC ICP HMP-03 Installation instructions and homeowner's manual

Pentair

Pentair ETi 400 installation guide

Hayward

Hayward ENP2M-9A Installation instructions manual

BriskHeat

BriskHeat TOT Series instruction manual

Hayward

Hayward C-SPA-XI 5.5 Installation & operation manual

Aquacal

Aquacal AEROTEMP Brochure & specs