9

PART 2 - SECTION I - INSTALLATION INSTRUCTIONS

PUMP SELECTION

The filtration pump must be sized to provide an

adequate water flow for the filtration system

and the heater. In some cases however, this

can cause a high back pressure which reduces

the filtration capacity and in this case it would

be more of on advantage to install an additional

pump for the heater only. This pump must be

installed on the inlet side.

DO NOT connect the pump to the heater outlet.

Some heater models incorporate their own By-

Pass Pump but this is used to control the

temperature of the water entering the heater to

prevent condensation and scale and will not be

suitable as the additional pump described above.

Refer to the Flow Rate chart following when

sizing the pump.

Where the water flow rate exceeds the

maximum shown in the chart, a by pass valve

must be installed to reduce the water flow

through the heater.

A pump run on timer must be fitted to remove

any residual heat from the boiler and prevent

any nuisance tripping of the high limit switch.

WATER FLOW RATES.

Model Water flow (l/sec)

min max

538 to 1292 4.5 7.5

1362 / 1412 1.9 3.2

1492 / 1552 2.2 3.5

1662 / 1722 2.5 4.1

1852 / 1922 2.8 4.4

2004 / 2214 3.2 5.0

2404 / 2634 3.8 5.9

2804 / 3164 4.7 7.2

3304 / 3694 5.6 8.4

3804 / 4224 6.2 9.4

We recommend that the pump be selected that

will deliver the maximum flow and the

installation of an external by-pass in all cases so

as to allow for the field adjustment if required.

IMPORTANT: When installing a new heater

to an old system, it is a Raypak

requirement that the system and its

equipment be inspected and if necessary,

drained and flushed out with clean fresh

water, before the new heater is

connected. Failure to do this may cause

blockages and/or heater damage which is

NOT COVERED BY WARRANTY and any

damage caused would result in extra

costs to repair etc.

IF THERE IS ANY DOUBTS ABOUT SYSTEM,

DRAIN AND FLUSH AS A PRECAUTION.

SYSTEM OVER TEMPERATURE

CUT OUT

The installation may require a "System -

Manual Reset High Limit", refer to AG601 and

other relevant codes.

AUTOMATIC CHEMICAL

DOSING EQUIPMENT

All automatic chemical dosing devices,

including salt chlorination, MUST be installed

downstream of the heater and in a manner that

will not allow the chemically dosed solution to

enter the heater before being thoroughly mixed

with the main pool or spa water.

PRESSURE RELIEF VALVE

The standard pressure relief valve supplied is

set to 410 kPa (60 PSI).

WATER SENSOR LOCATION

On models 1362 to 4224, where a By-Pass

pump is an integral part of the heater, the

water sensor of the Digital Thermostat is

supplied with the unit but it is not installed to

the pipework.

Please insert the sensor as shown in the

drawing below.

ELECTRICAL WIRING

The electrical power consumption of the

heaters is:

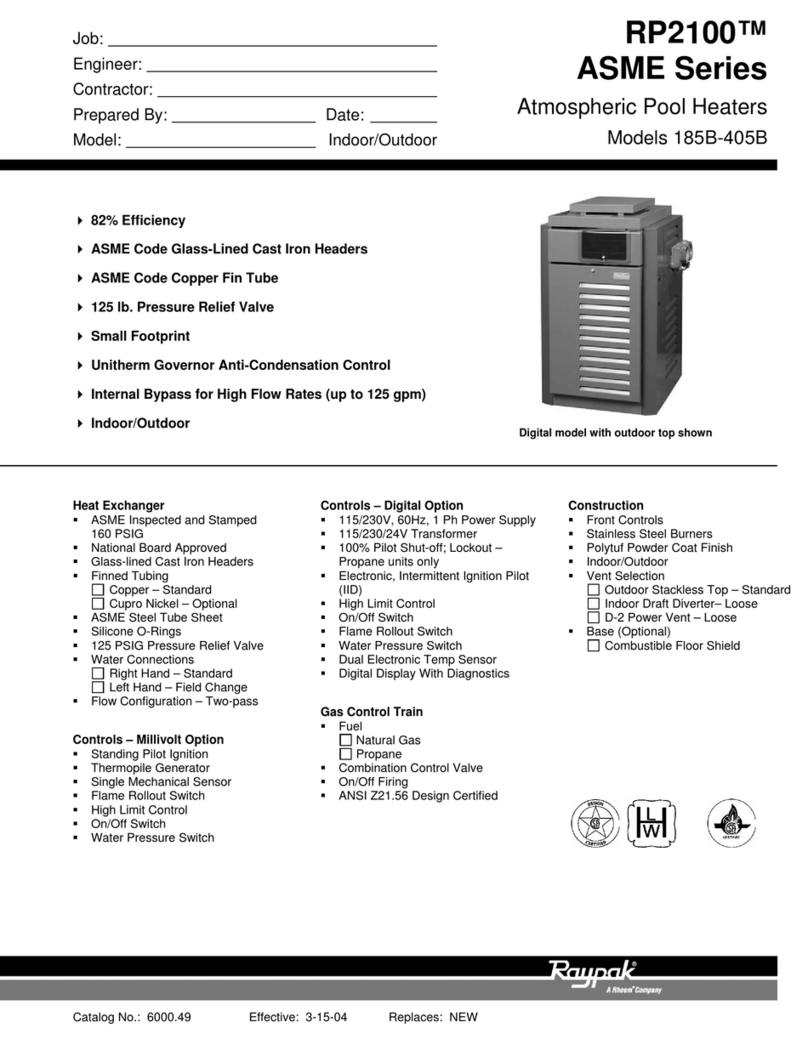

Models 538 - 1292 (No By-Pass Pump):

240 Volts AC, 50/60 Hz, 100 VA approx.

Models 1362 - 1922 (UPS 32-80B By-Pass Pump):

240 Volts AC, 50 Hz, 1.4 Amps approx.

Models 2004 - 3164 (UMT 50-30Z By-Pass Pump):

240 Volts AC, 50 Hz, 3.0 Amps approx.

Models3304 - 4224 (UMT 50-60Z By-Pass Pump):

240 Volts AC, 50 Hz, 3.0 Amps approx.

A normal 10 or 15 Amp, single phase power

circuit would be suitable.

Access to the electricals is achieved by

removing the cover of the control panel. (See

Location of Controls for different models.)

The heater must be properly earthed and

Raypak highly recommends the installation of

an RCD (Residual Current Device) for added

electrical safety. If the site is "electrically

noisy", a mains filter can be supplied at extra

cost, to eliminate failures.

THE HEATER MUST NOT BE ABLE TO

OPERATE WITHOUT THE CIRCULATING

WATER PUMP RUNNING.

The heater (240 Volts) power supply must be

"interlocked" via the auxiliary contacts of the

pump contactor (relay) etc or alternatively the

power supply for the pump and the heater

must operate off the same circuit and isolation

switch. (Parallel connection)

A Flow Switch is not regarded as an

interlock and must not be used as one.

Any other form of interlocking must be

approved by Raypak.

A pump run on timer is required so that at any

time that the heater is no longer required, the

heater shuts off and the pump continues for at

least ten (10) minutes.

A Raypak "economaster" is an optional extra

available at extra cost for all heaters.

For servicing purposes we suggest that the

isolation switch be installed as near as

practical to the heater.

If there is any control wiring etc which is not

isolated by this switch then a suitable warning

label must be affixed to the heater which will

also direct the service person to the isolation

switch for that particular wiring. E.G. More than

one isolation switch is required to turn off the

power supply, Extra switch(es) on switchboard

etc.

Caution: Do not locate cables in front of or

underneath the burner, please consult Raypak

for advice if unsure.

Where cables or conduit, trunking etc are to be

mounted on the heater casing, please keep at

least 10mm air gap from the heater casing to

eliminate possible overheating.

Do not locate cables etc where they will

restrict access covers, doors etc.

Where the clearance from the right hand side

of the heater (models 538 to 1922) is

restrictive, please notify Raypak at the time of

manufacture and we may be able to relocate

the control panel for a minimal extra cost, if

this is not possible then a field retrofit may be

the best solution. (At extra cost)

There are many variations to the types of

controls available and also RUN & FAIL indication

can be supplied. Ask Raypak what is available.