3

General Safety Rules for

Woodworking Machinery

WARNING

The operator must thoroughly read and un-

derstand this manual before operating the

cut off saw or starting any servicing. All

safety and warning instructions should be

followed. This manual must be available to

all operators.

1. For your own safety, read the operation manual carefully. Know your machine. Learn its applications and

limitations, and any hazards specific to this machine. All personnel should be trained in the operational pro-

cedures and received safety instruction before operating this equipment. If you have not received proper

training in the use of this machine, DO NOT OPERATE THIS MACHINE, damage to the equipment or injury

to the operator is possible.

2. This machine should not be operated without all of the guards in place and safety devices in operation. Re-

moval of any guards or disabling any of the safety devices may result in damage to the equipment or injury

to the operator. If any of the guards or safety devices are missing, damaged or not working properly, DO

NOT OPERATE THIS MACHINE, notify your supervisor immediately.

3. If the operator has any safety concerns or questions regarding the operation of this equipment, DO NOT

OPERATE THIS MACHINE, the machine should be locked out and your supervisor notified immediately.

4. All Lock Out/Tag Out procedures must be followed before servicing or adjusting this equipment. If you have

not received proper training in the Lock Out/Tag Out procedures for this machine, DO NOT OPERATE THIS

MACHINE, damage to the equipment or injury to the operator is possible.

5. In case of any equipment malfunction or jam the machine should be powered off and locked out before

clearing any materials from the operational areas of this machine. Once cleared the reset procedures need

to be followed when powering up the equipment. At no time should any of the machine control systems in-

cluding electrical, hydraulic or pneumatic circuits be manually overridden.

6. Check machine for damaged parts. Before continued machine use any damaged guard or part must be

carefully checked for proper operation of its intended function. Check all moving parts for proper alignment,

check for binding of moving parts, breakage of parts, proper secure mounting, and any other condition that

may affect machine operation. Guards or other parts that are damaged must be properly repaired or re-

placed.

7. Machine must be properly grounded.

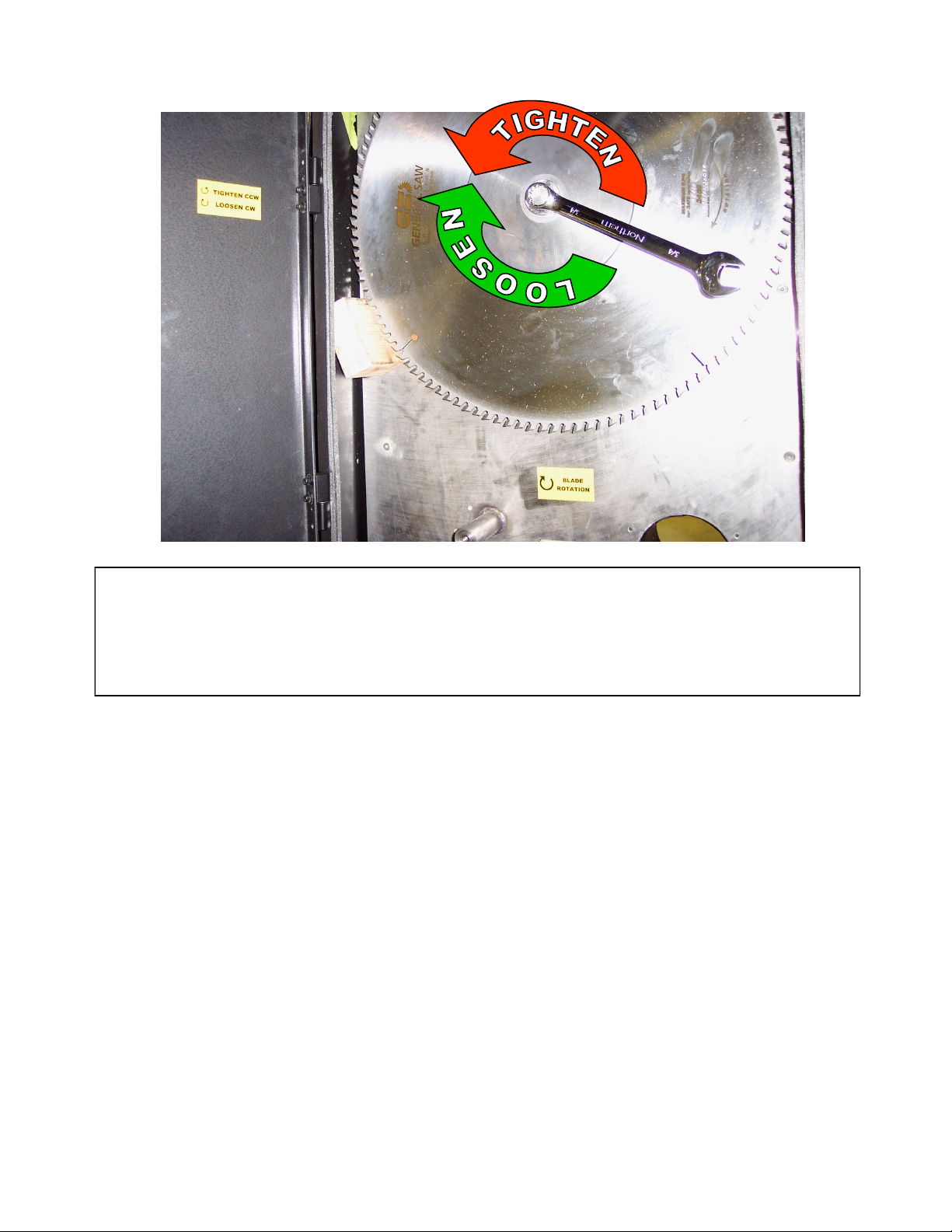

8. Maintain and clean machine at recommend intervals. Intervals may need to be adjusted due to work load or

material type to keep machine in top condition. Follow instructions for lubrication, setup, and changing ac-

cessories.