Contents

1. Safety precautions............................................................................................................ 4

1.1. General safety ............................................................................................................... 4

1.2. Other precautions .......................................................................................................... 8

2. Description of symbols...................................................................................................... 9

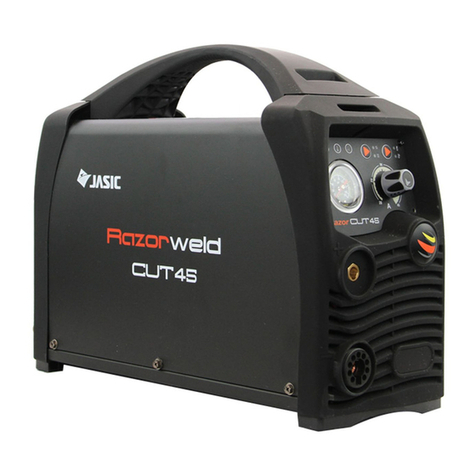

3. Product overview .............................................................................................................10

4. Technical parameters.......................................................................................................11

5. Installation .......................................................................................................................12

5.1. External interface description .......................................................................................12

5.2. Power installation..........................................................................................................13

5.3. Connection of cutting torch, earth cable and gas pipe..................................................14

6. Control panel ...................................................................................................................15

6.1. Overview.......................................................................................................................15

6.2. Display of parameters and error codes.........................................................................15

6.3. Parameter adjustment knob..........................................................................................16

6.4. Selection of working mode............................................................................................16

6.5. Gas check function .......................................................................................................16

6.6. Electrical current settings for cutting.............................................................................17

6.7. Protective indicators .....................................................................................................17

6.8. Engineer mode .............................................................................................................17

6.9. Restoring factory settings .............................................................................................17

6.10. Barcode display ..........................................................................................................18

7. Cutting function operation................................................................................................18

7.1. Cutting operation ..........................................................................................................18

8.1. Power supply maintenance...........................................................................................20

8. Troubleshooting ...............................................................................................................21

9.1. Common malfunction analysis and solution..................................................................21

9.2. Alarm and solutions ......................................................................................................22

9. Packaging, transportation, storage and waste disposal...................................................22

10.1. Transportation requirements.......................................................................................22

10.2. Storage conditions......................................................................................................23

10.3. Waste disposal ...........................................................................................................23

Appendix 1: Wiring diagram of CUT45PFC .........................................................................24

Appendix 2: Exploded-view drawing of CUT45PFC ............................................................25

Appendix 3: List of common spare parts - CUT45PFC........................................................26

Appendix 4 How Plasma works............................................................................... ...........27

Appendix 5:List of Warranty Explanations..........................................................................31

Appendix 6:California Prop 65 Statement...........................................................................34

Appendix 4:List of common Torch spare parts - J45XC.....................................................30