Speed measurement

In the "Setup"tab of the app,

indicate the number of poles for

the motor you are using. Press

the icon for help on pole

counting.

12

Support and warranty

13

For feedback of questions regarding the installation of the device,

RCbenchmark products are fully tested and inspected before

shipping. This product is covered by a one year warranty on

manufacturing defects.

The warranty does not cover misuse, product modifications, and

reverse polarity connections. When testing at high voltage, do not

use an ESC with a break setting activated. The breaking over-

voltage could damage the power measurement circuit.

Included

-Assembly manual (1)

-Data acquisition board (1)

-Calibration bar (1)

-Calibration weight (200g)

-Black knobs (2)

-Motor mounting part (1)

-Lower structural part (1)

-Upper structural part (1)

-Power cables (2 x 75cm)

-Load cell 2 kg (2)

-Load cell 5 kg (1)

-L-Brackets (2)

-Tie-wraps (≈10)

-Hex keys (3)

-Washers to install motors (1 bag)

-USB cable (1)

-M5 12mm (6)

-M4 12mm (4)

-M4 5mm (12)

-Spacers (2)

-Washers M4 (2)

-RPM probes (1 + 1 extra)

The mechanical load on the motor is controlled by changing the

throttle and by installing a propeller of different size or pitch. You

may also perform your tests at multiple voltages.

You can manually control the motor for your tests and record

your data manually or continuously. These options are available

in the "Manual Control" tab.

You can also use the supplied scripts in the "Automatic Control"

tab to test and record motor data automatically.

If you have special testing requirements, you can use our very

powerful scripting functionnality. You have access to the full

power of Javascript, can control the dynamometer, export data,

and much more through our API. Example applications include

motor certification for production or repeatable tests for

characterization and research.

Motor and propeller testing

14

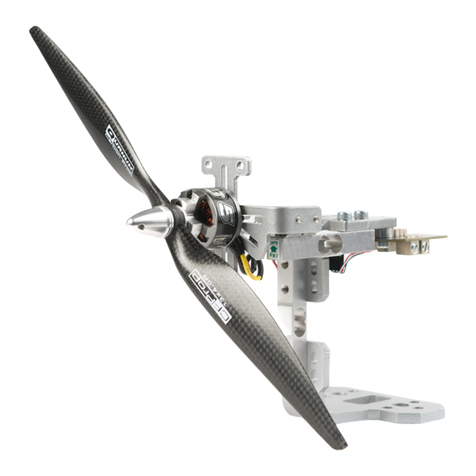

ESC +

ESC -

Attach using tie-wraps

or double-sided tape

ESC signal

Do not

reverse

polarity

Insert or solder

RPM probe in

connector

2x C-clamp for

attaching to

table