CHARGEMASTER DISPENSER INSTRUCTIONS

Your newChargeMaster Dispenser is an

exciting advancement in reloading

technology.It is not only fast and convenient,

but canstore up to 30of your favorite loads.

Once you programthe unit, you can recall

the stored charge and dispense it with

precisionand accuracy. The ChargeMaster

is fast andrepeats with the accuracy you’ve

come to expect fromRCBS.

GettingStarted:

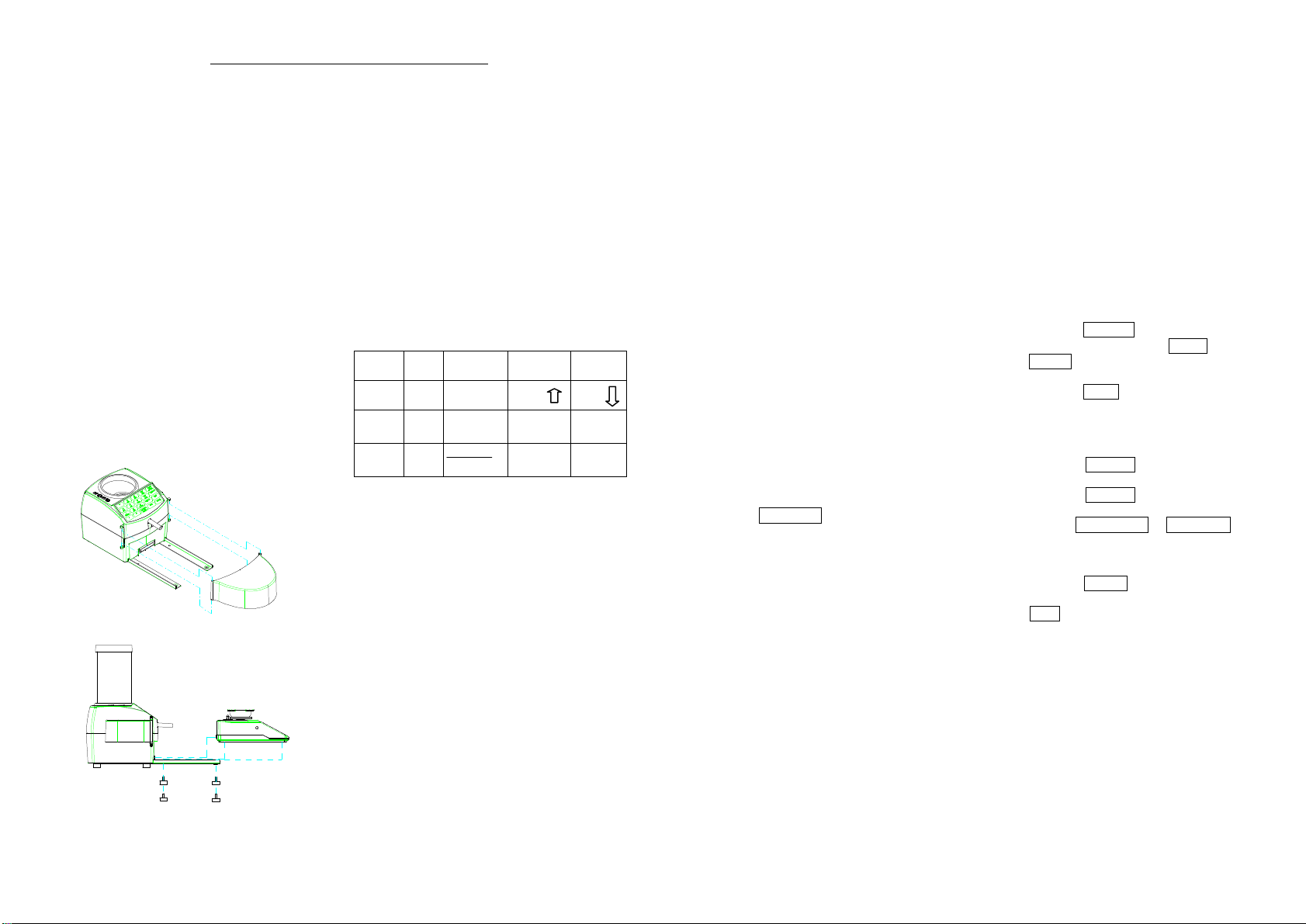

The ChargeMaster Dispenser is used in

conjunction with the ChargeMaster 1500

Scale. The ChargeMaster scale simply plugs

into thedispenser. Thetransformer on the

ChargeMaster scalesupplies thepower for

the ChargeMaster Dispenser. If you

purchase your ChargeMaster as aCombo

Unit, the Scale& Dispenser are

preassembledintoa single unit. The two

units are solidly mounted into one unit using

two rigid steelbrackets onthe underside of

the Dispenser and Scale. If you purchased

your ChargeMaster Scaleand ChargeMaster

Dispenser separately, you will need to

assemble the two units.

Step 1.To attachthescale to the dispenser,

remove the 4 screws on the bottom of

the scaleand slide the scalealongthe

rails until the two units are plugged in

together. Replace the screws andhand

tighten. DONOTOVER TIGHTEN.

Step 2.The ChargeMaster dispenser comes

equipped with a wind guard. This allows

you to load inconditions that most scales

will not handle.

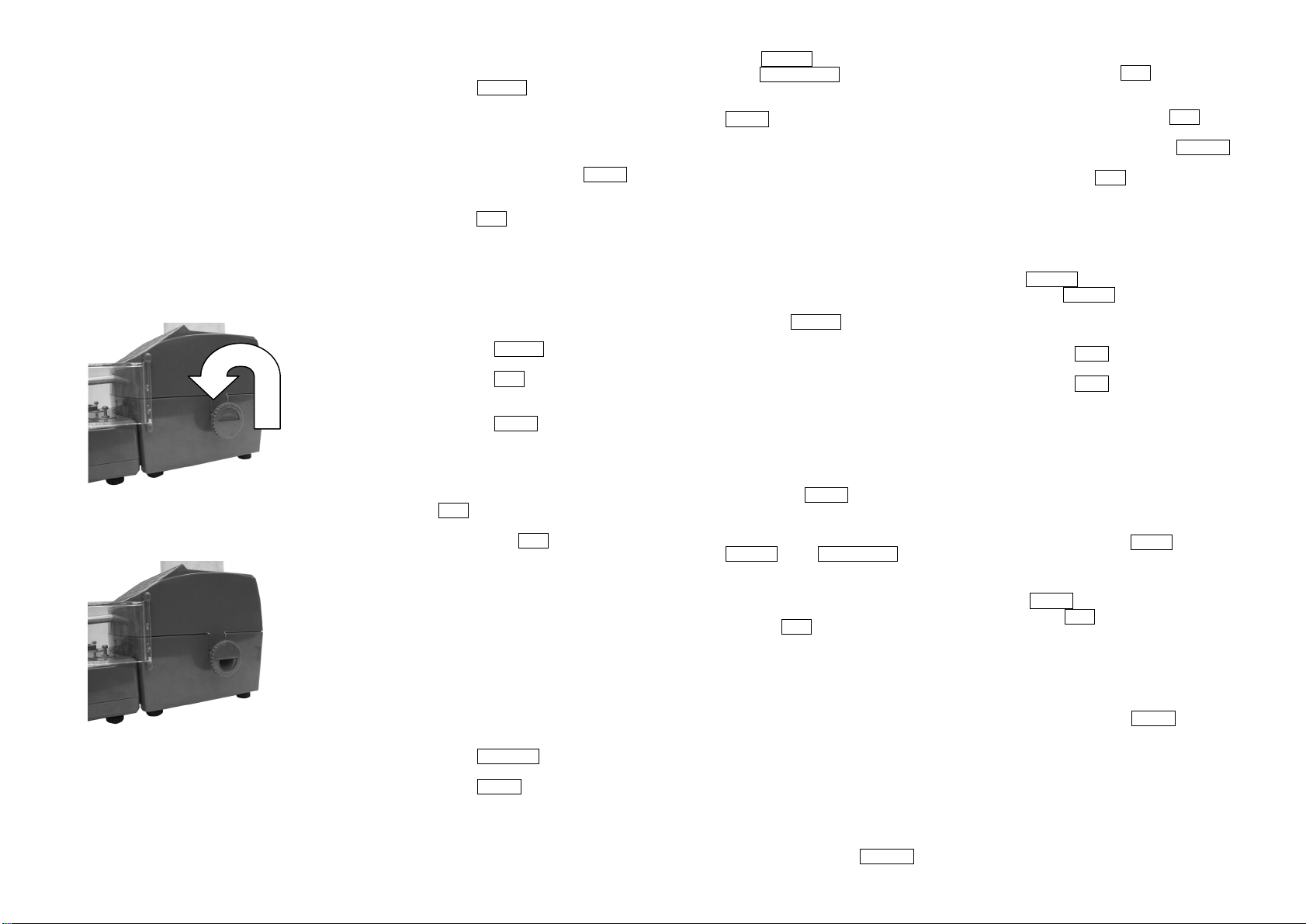

Step 3.The knob onthesideof the dispenser is

the drain. To open the drain turn knob½

turn, twist it to remove the powder left in

the dispenser. It is not agood idea to

allowthe powder to remainin the hopper

for long periods of time.

DISPENSER - KEYPAD

FUNCTION DESCRIPTION

1 2

ABC

3

DEF EDIT

MEM BACK

SPACE

4

GHI 5

JKL

6

MNO NEW

MEM TRICKLE

7

PQRS

8

TUV

9

WXYZ RECALL

DISP

.0 CANCEL

STOP MEM ENTER

BACK SPACE: Deletes thelast digit

displayed on the farright sideof the LCD

Display window. Each timeyou push this

key it deletes onemore digit.

TRICKLE ò:Manual operation to dispense

the powder or scrollthrough load data

in memory

DISP: Press key to dispense thepowder

once you have entered agiven charge

ENTER: Confirmyour charge

EDITMEM: Edit theLOADDATA MEMORY

data

NEW MEM ñ:Sets the newmemory data or

scrolls through load data inmemory.

RECALL: Recalls theLOAD DATAMEMORY

data

MEM: This recalls the LOAD DATAMEMORY

data by memory number, 01 through 30.

Press until you get tothecharge you

want to dispense or enter.

CANCEL/STOP: Clears the data or stopthe

operation

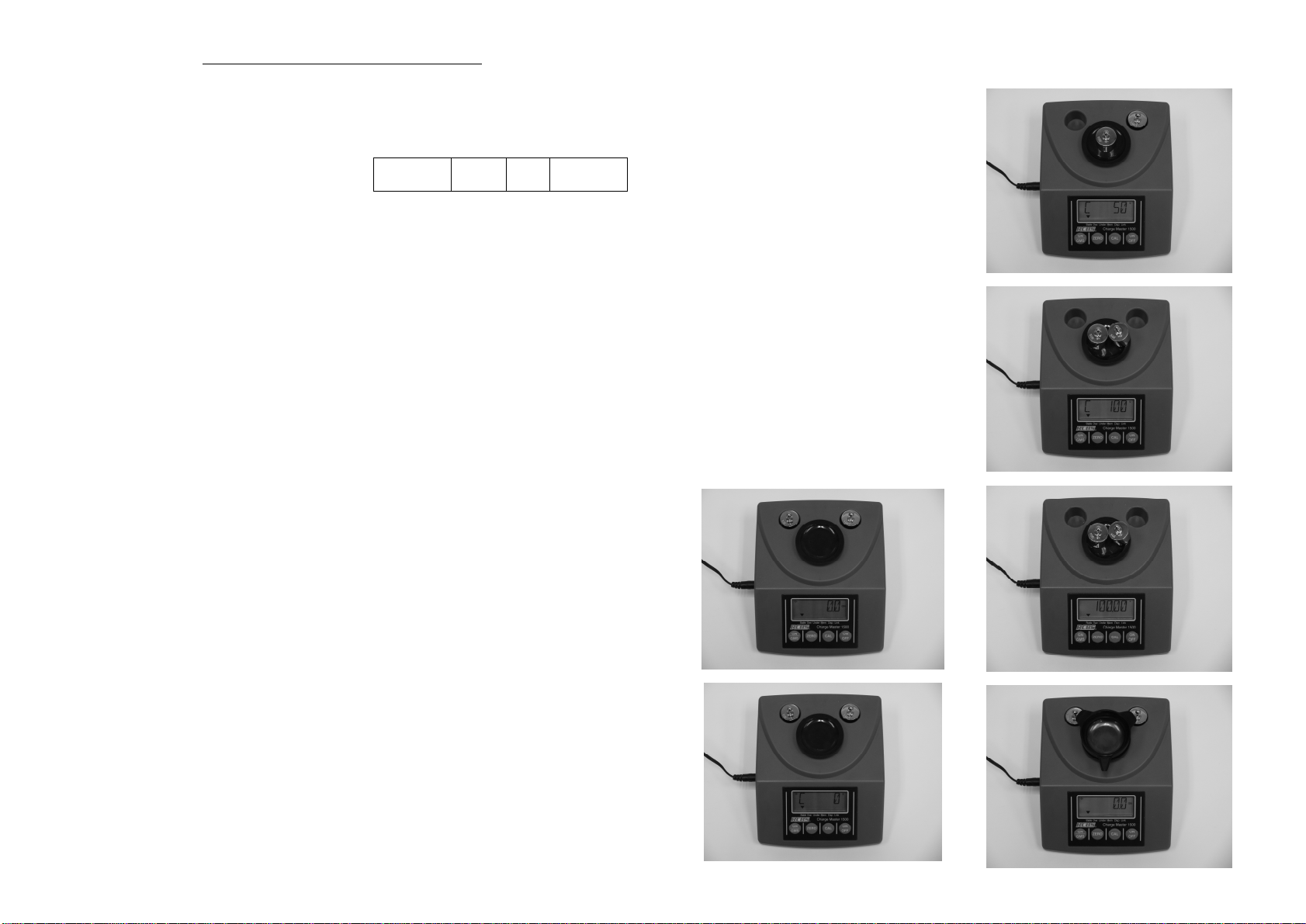

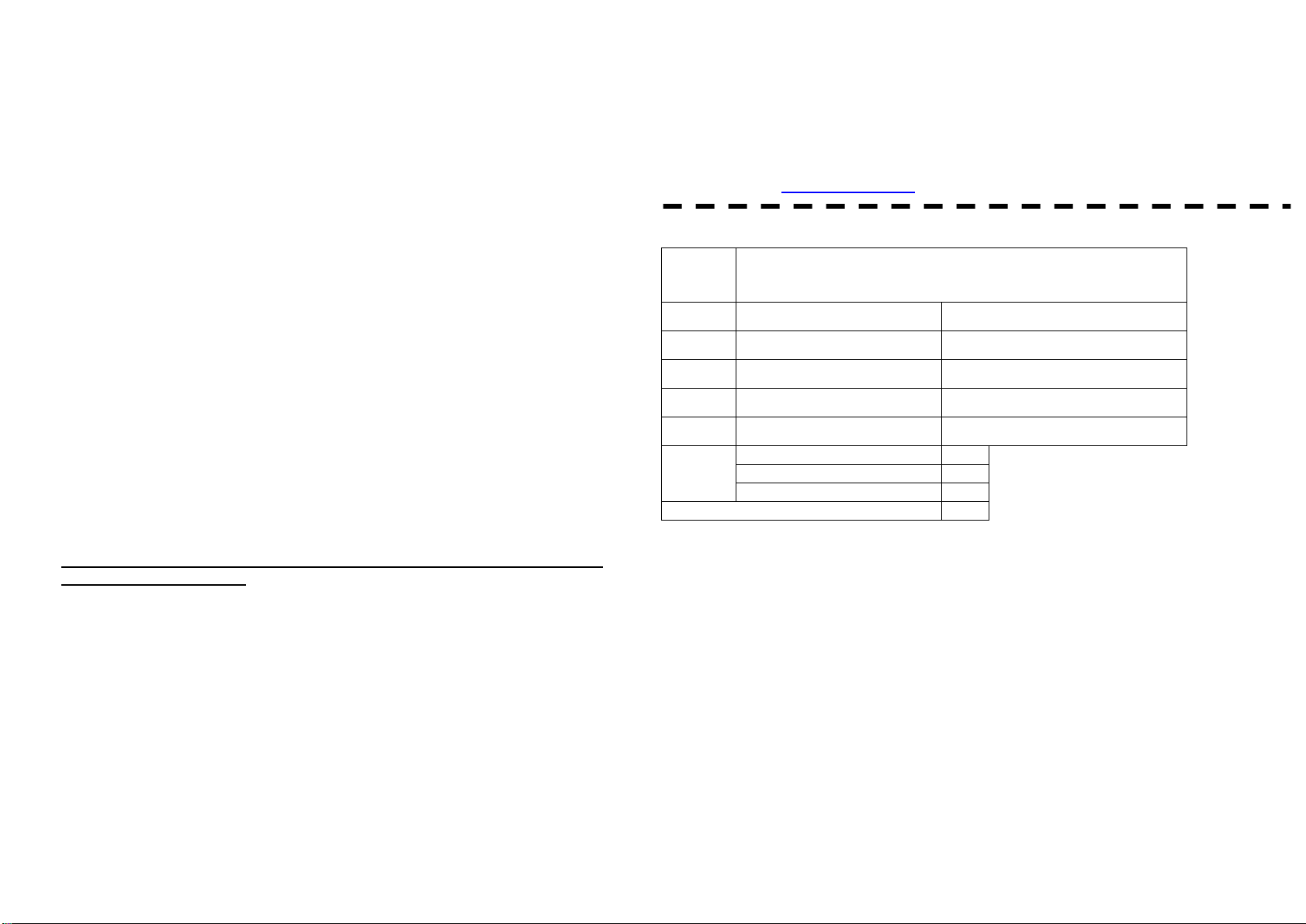

SCALE - DISPLAYPANELDESCRIPTION

StableOver Under Mem Disp Link

Stable: The black arrowindicates the weight is

stable

Over: The black arrowindicates the powder

weight in the pan is higher than the set value

Under: The black arrowindicates the powder

weight in the pan is lower than theset value

Mem: The black arrowindicates the desired

weight as set in theLOADDATA MEMORY

Disp: Theblack arrowindicates powder is

being dispensed from theDispenser to the

Scale

Link: The black arrowindicates that the

dispenser andscale communication link is

established

LOAD DATA MEMORY CONFIGURATION:

Eachmemory has four items of data:

C=_ (Cartridge), this is thename or number of

the cartridge

B_ (Bullet weight), this is the weight of the

bullet used.

P=_ (Powder type), this is forthe nameor

number of the powder

W_(Weight of powder), the charge is entered

here

CONFIGURE NEW LOAD DATA MEMORY

(30 memorystores available)

To exit dispenser and revert back to scale

modepress ZEROKeyon your scale.

Step 1.Press the NEWMEMkey to start the

process

Step 2.The first time you programMEM=0 will

showon the display. (MEM=01, 02, 03 and

so on through MEM=30 will appear on the

screen as each MEM field is used).

Step 3.Press the ENTER key, the display will flash

“CART”and thenshowC=. Keyinthe

cartridge one number/letter at a time. To

select aletter continue to push the

appropriate key until the desired letter

appears. After you select the appropriate

number/letter, you will need towait untilthe

keys stop flashingto proceed tothe next

number/letter. There are 5 spaces

available to enterthe cartridgename.

When you’ve selected the cartridge name

press ENTER.

Step 4.The displaywill flash “B_WT”and shows

“B_”. Key inyour bullet weight and press

ENTER.

Step 5.The displaywill flash “POWD”and shows

P=. Key in the powder name. Remember

that you’llneed toscrollthrough the keys

until you get totheletter you want. Allow

the letter/number to stopblinking before

you proceed to the next letter/number. You

have 5 spaces to enter your powder name.

When you have your powder name on the

display, press ENTER.

Step 6.“WT”will flash and then thedisplay will

show “W_”. Key in the powder charge and

press ENTER.

Step 7.The configuration of this memory is now

complete.

Step 8.Afteryouhave finishedthe current memory,

the display will be ready for the next

memory number to be stored. Youmay

repeat the above steps until you have

entered all your informationup to30

selections.

Note 1: Press the CANCEL key todelete the

data in afield. Press theBACK

SPACEkey to clear theprevious digit.

Note 2: Press the ZEROkey onyour scale at

any timeto exit the dataedit process.

RECALLTHE LOAD DATA MEMORY:

Step 1.Press the RECALLkey, the display will

show “C=_ ”

Step 2.Press the RECALLkey again, the

display shows the first memory setting.

Step 3.Use theNEWMEMñor TRICKLEò

keys to scroll through the stored

memory. When thedisplay shows the

memory that your are looking for,

press the ENTERkey.

Step 4.Afteryou have selectedit, press the

DISPkey, and the powder feed tube

will start todispense the powder.

ChargeMaster 1500 -5- SME300000080 ChargeMaster 1500 -6- SME300000080