7

RCT. Simplify monitoring.

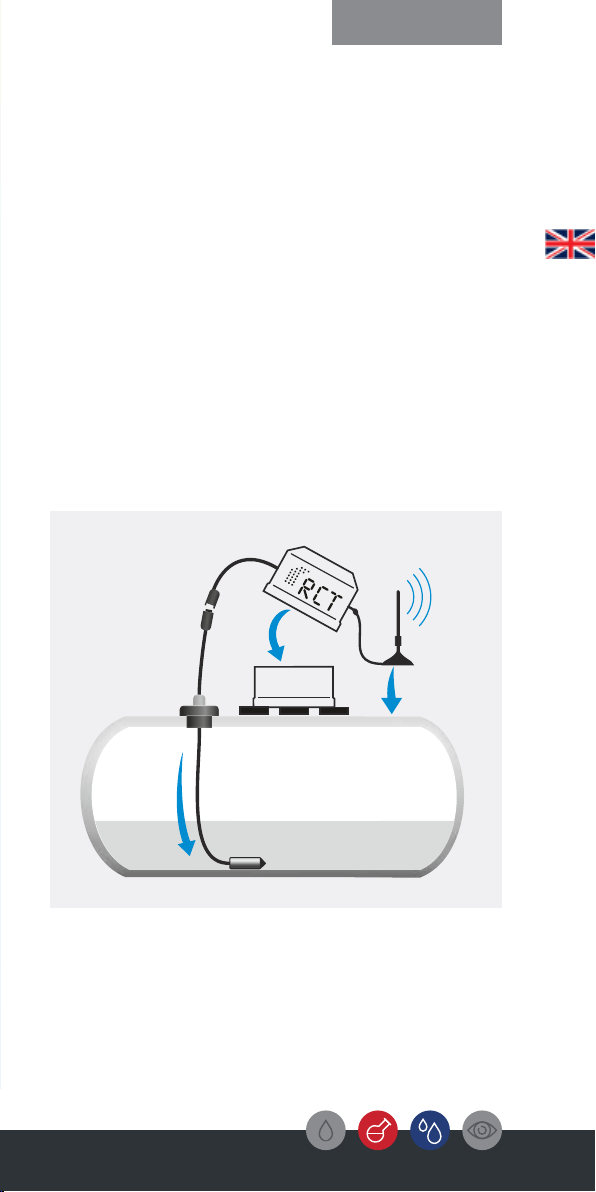

Fig. 2 | Pressure probe with screw plug

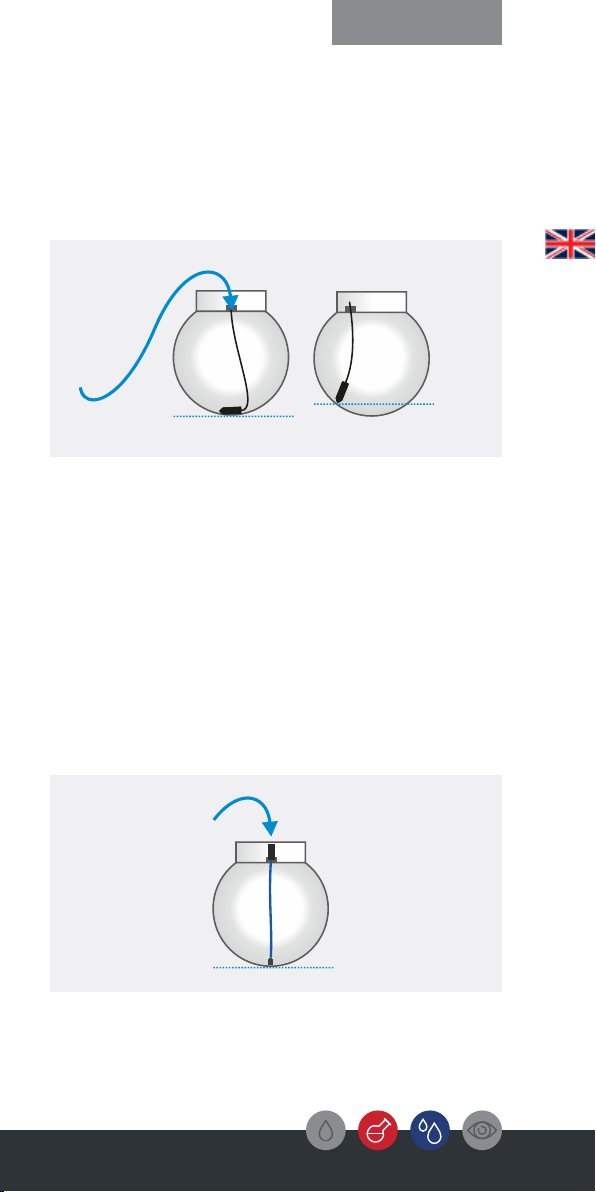

Fig. 3 | Capacitive sensor

Step 1: Zero adjustment

For the pressure probe:

(Fig . 2)

(Fig. 1, Page 5)

Completing the zero adjustment

For the capacitive sensor:

(Fig. 3)

(Fig. 1, Page 5)

Operation

Carefully cut the white transportation straps that

hold the pressure probe together. For proper

installation, the probe must be free of twists.

Therefore, leave the probe hanging to straighten

the cable. This may take some time depending on

the temperature.

Mount the antenna of the transmitter and place it

on a metal surface with the magnet. Connect the

pressure probe to the transmitter via the screw

connector and activate the device by plugging in

the battery. Remove the black safety

sticker placed over the contact before plugging it

together.

Mount the antenna of the transmitter and place it

on a metal surface with the magnet. Connect the

capacitive sensor to the transmitter via the plug

connection and activate the device by plugging in

the battery.

Remove the black safety sticker placed over the c

ontact before plugging it together.Make sure that the

sensor does not come into contact with conductive

materials during the measurement time. When the

red and green LEDs light up, the measuring process

is finished. The capacitive sensor can be placed on

the floor.

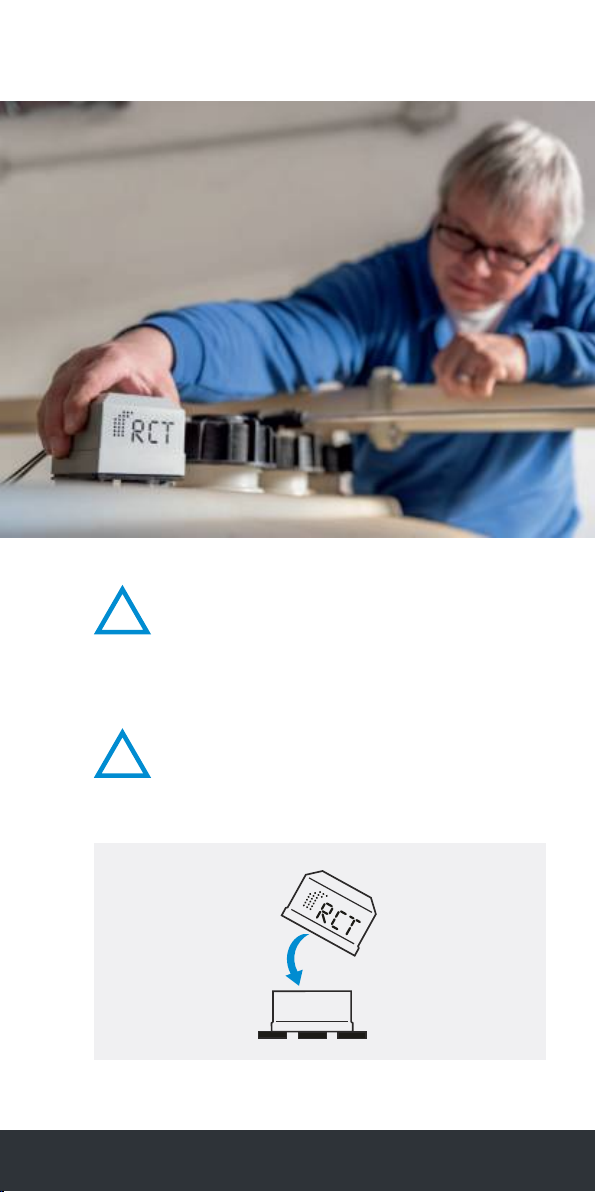

Then wait about one minute until the device has

sent the data. You can optionally see this in the

Mobile App "RCT Monitor" (see step 6).

The transmitter unit has now transmitted an AD

value to the server, which represents an empty

tank - on the condition that the probe did not come

into contact with other media or liquids during the

measurement. Via the Mobile App or Web App you

can see this transmitted AD value, which is usually

between 10 and 200. Please now assign this value

via the App or Web App as 0%, 0 cm, or 0 liters

(depending on the desired physical unit of size).

This completes the zero adjustment.

Then disconnect the device from the battery again

and go to step 2.