Refrigerant Recovery - Pass Through Method

This method of recovery uses the unit to pull the refrigerant from the plant and

discharge it direct to a suitable recovery cylinder. This method is best suited to

applications where up to 3kg of refrigerant is to be recovered.

Use a manifold gauge set to connect to both high and low sides of the plant. If

possible connect to the plant on the high side at a point where the refrigerant

will be in liquid form. Connect the centre hose to the unit inlet.

Connect the discharge of the unit to a suitable recovery cylinder. Ensure that

the recovery cylinder has sufficient free volume to accept the refrigerant you

are going to recover and is monitored by a weigh scale. Zero (Tare) the scale

Open the valves at the plant and cylinder.

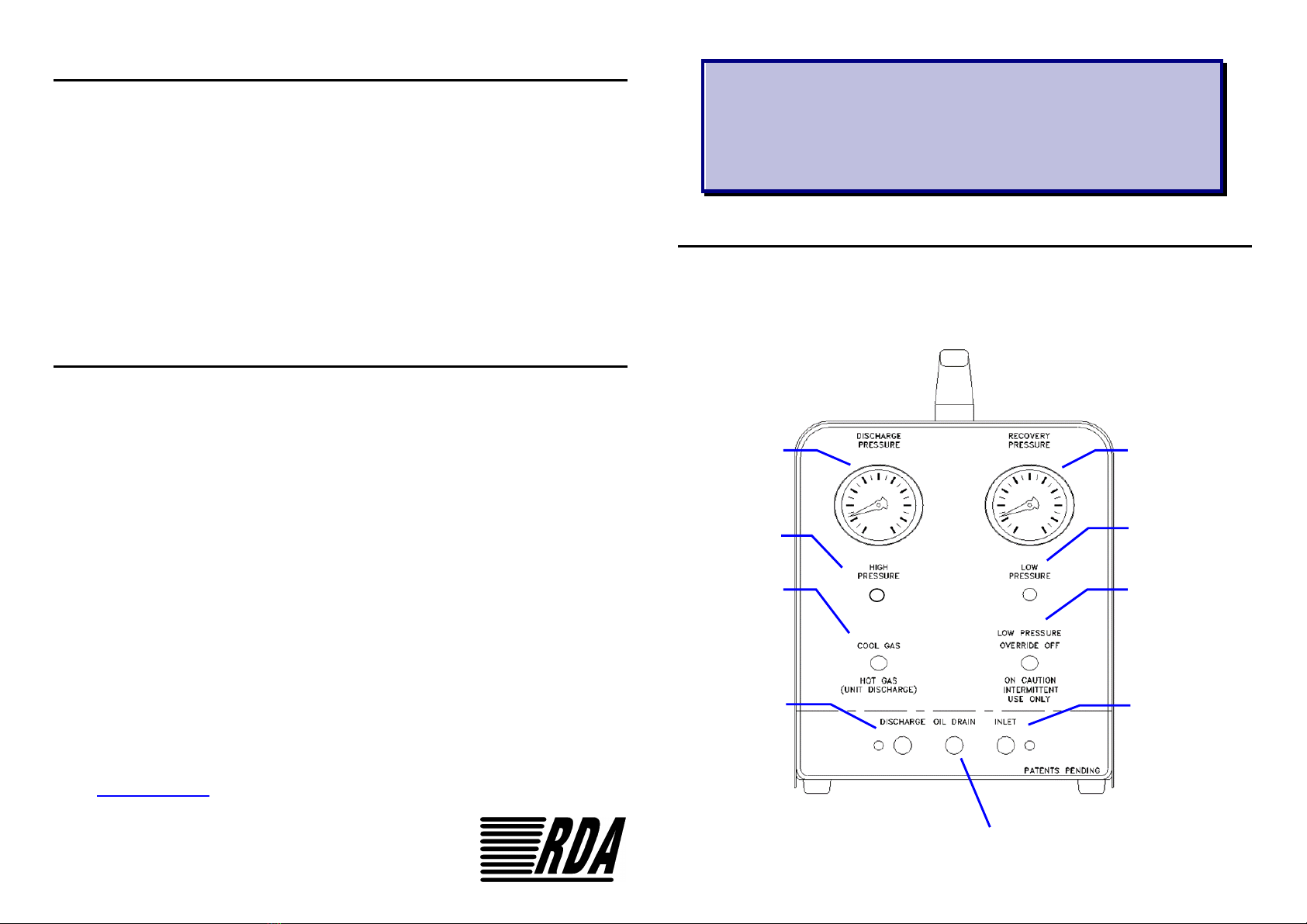

Set the selector switch to Coolgas.

Switch the Unit ON at the mains socket.

The unit will start to recover refrigerant. You will hear the HC-3 click as it recovers

refrigerant. When the entire liquid refrigerant has been recovered the clicking will

stop and the pressure on the unit gauge will begin to fall. When the inlet pressure

reaches 0 bar the unit compressor will automatically stop.

Close the inlet hose valve and operate the LP override ON and allow the unit to

run for 1 minute maximum to complete the recovery.

Switch the unit OFF at the mains socket and close all valves and disconnect

hoses.

Record the mass of refrigerant recovered.

Refrigerant Recovery - Push - Pull Method

This method of recovery uses the unit to pressurize the refrigerant in the plant so that it can be

discharged directly to a suitable recovery cylinder. This method is best suited to applications where

more than 3kg of refrigerant is to be recovered.

Connect the inlet connection of the unit to the vapour port of a suitable twin ported recovery

cylinder.

Connect the discharge of the unit to a suitable point on the plant where the refrigerant will be in

vapour form.

Connect a hose from a liquid port on the plant to the liquid connection on the recovery cylinder.

Ensure that the recovery cylinder has sufficient free volume to accept the refrigerant you are going

to recover and is monitored by a weigh scale. Zero (Tare) the scale

Open the valves at the plant and cylinder.and switch the unit On at the mains socket.

Set the selector switch to Hotgas.

The unit will start to recover refrigerant from the cylinder, which will reduce the pressure within the

cylinder. At the same time the unit will discharge into the plant which will raise the pressure. The

pressure difference between the plant and the cylinder will result in refrigerant transfer. You will hear

the HC-3 click as it recovers refrigerant.

When the bulk of the refrigerant has been recovered, reconfigure the set up to the

Pass Through method to remove the remaining refrigerant vapour. When the inlet

pressure reaches 0 bar the unit compressor will automatically stop.

Close the inlet hose valve and operate the LP override ON and allow the unit to run for 1 minute

maximum to complete the recovery. Switch the unit OFF at the mains socket.

Close all valves, disconnect hoses.and record the mass of refrigerant recovered.