4

DET3 Series

1.0 Safety • Safety Labels and Locations • Clearance to Combustibles

Clearance to Combustibles is defined as the minimum distance that must exist between the tube surface,

or reflector, and any combustible items (see Figure 1.1). It also pertains to the distance that must be

maintained from moving objects around the tube heater.

Clearance to Combustibles

®

DETROIT RADIANT PRODUCTS COMPANY

21400 HOOVER ROAD - WARREN, MI

RE-VERBER-RAY INFRA-RED RADIANT TUBE HEATER

FOR OUTDOOR USE AND INDOOR (Non-Residential) INSTALLATION ONLY.

Class IIIA Permanent Label

(586) 756-0950 - www.drp-co.com

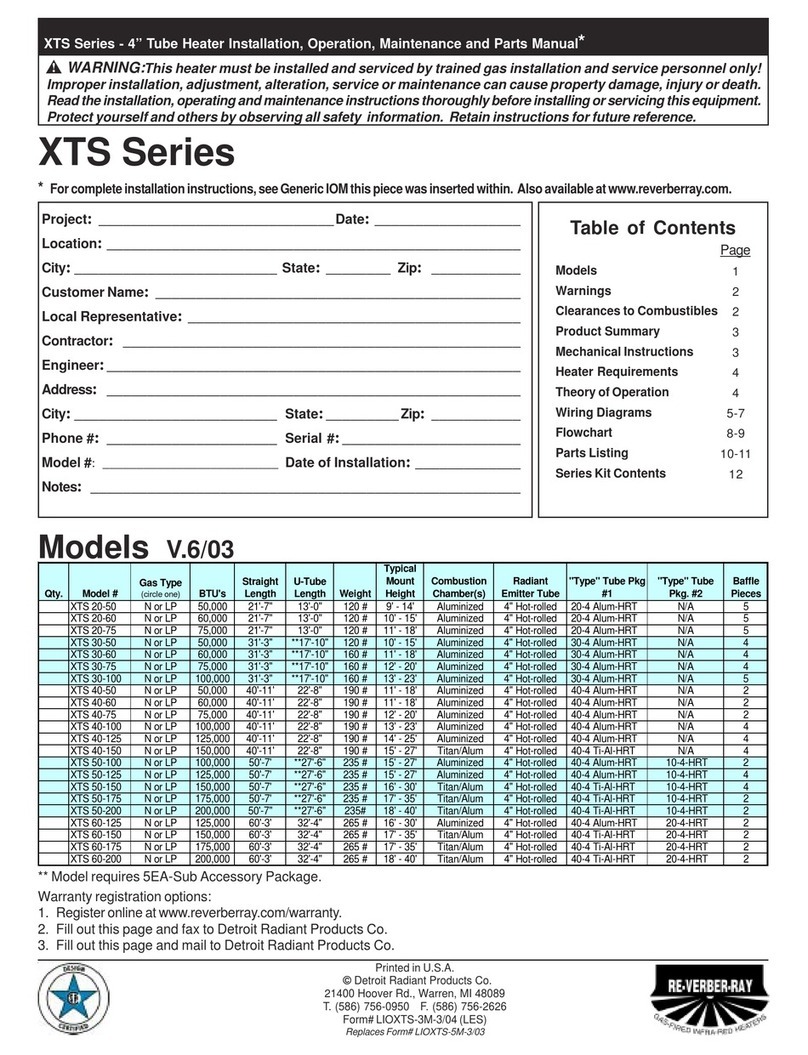

Volts AC:

AMPS - Starting:

AMPS - Running:

Combustion Chamber:

120V - 60Hz

1.7

1.1

4” Black Coated Aluminized

DESIGN COMPLIES WITH:

ANSI Z83.20b-2004-GAS FIRED LOW INTENSITY INFRA-RED HTR.

Manifold Pressure:

Maximum Inlet Pressure:

Minimum Inlet Pressure:

3.5 in.

14 in.

5.0 in.

W.C.P.

W.C.P.

W.C.P.

Serial No.: 0807XXXXXXXXXX 0001

MODEL NO.

DET-40-125N(-3)

Heater Type

Minimum Mounting Angle:

Maximum Mounting Angle:

C1

0

45

DEGREES

DEGREES

INPUT BTU/H

125,000 / 95,000

FOR USE WITH

Natural Gas

®

DETROIT RADIANT PRODUCTS COMPANY

21400 HOOVER ROAD - WARREN, MI

RE-VERBER-RAY INFRA-RED RADIANTTUBE HEATER

FOR INDOOR (Non-Residential) INSTALLATION ONLY.

Class IIIA Permanent Label

(586) 756-0950 - www.drp-co.com

Volts AC:

AMPS - Starting:

AMPS - Running:

Combustion Chamber:

120VAC - 60Hz

1.7

1.1

4” Black Coated Aluminized

DESIGN COMPLIES WITH:

ANSI Z83.20b-2004-GAS FIRED LOW INTENSITY INFRA-RED HTR.

Manifold Pressure:

Maximum Inlet Pressure:

Minimum Inlet Pressure:

3.5 in.

14 in.

5.0 in.

Inches W.C.P.

Inches W.C.P.

Inches W.C.P.

Serial No.: 1208XXXXXXXXXX 0001

MODEL NO.

DET-40-125N(-3)

Heater Type

Minimum Mounting Angle:

Maximum Mounting Angle:

C1

0

45

DEGREES

DEGREES

INPUT BTU/H

125,000 / 95,000

FOR USE WITH

Natural Gas

SERVICE ACCESS PANEL

IGNITER & FLAME SENSE COMPARTMENT

1. Disconnect gas & electricity.

2. Remove cover by lifting top

coverupward and outward.

CAUTION: HOT SURFACE.

KEEPCOVER IN PLACE. REMOVE FOR SERVICE ONLY.

AVOID EQUIPMENT FAILURE

THIS 10 FT. TUBE IS THE

COMBUSTION CHAMBER.

THIS TUBE MUST BE THE FIRST TUBE

FOLLOWING THE BURNER CONTROL BOX.

!

INSTALLER

The combustion chamber utilizes either 409

stainless, titanium alloy or aluminized steel -

depending on the model number of your heater.

Rotate the tube’s welded seam to bottom.

Consult the manual(s) for further details.

F/N: LLTB004 (orange)

WARNING

Placement of explosive objects, flammable objects, liquids and vapors close to

the heater may result in explosion, fire, property damage, serious injury or death.

Do not store, or use, explosive objects, liquids and vapor in the vicinity the heater.

Burner Control Box Component Label

(affixed to center valve compartment lid)

Rating

Plate

Fan

Compartment

16” Burner

Tube

Primary Combustion

Chamber

Secondary Combustion

Chamber (if applicable)

ALUMINIZED TUBE

(This is the Second Chamber)

This tube is constructed of aluminized coated steel and must be

placed directly after the titanium coated “Combustion Chamber”

(orange labeled tube).

150,000-200,000 Btu/h

models only

F/N: LL01 - Clearance Safety Tag

(Affix adjacent to heater’s thermostat)

Controls

Compartment

F/N: LLTB026 F/N: LLTB024R

F/N: LLTB025L

SERVICE ACCESS PANEL

IGNITER & FLAME SENSE COMPARTMENT

1. Turn off gas & electricity.

2. Remove cover by lifting top

cover upward and outward.

CAUTION: HOT SURFACE.

KEEP COVER IN PLACE. REMOVE FOR SERVICE ONLY.

SERVICE ACCESS PANEL

SERVICE ACCESS PANEL

DET-40-125N(-3)

Data on this label is for the model shown on this label. If your heater has been converted,

this information is not accurate. Please contact the factory for assistance.

BURNER COMPONENTS:

For parts replacement information, contact factory at 586-756-0950 or visit www.drp-co.com/parts.

Serial No.: 0804XXXXXXXXXX 0001

Gas Valve:

Circuit Board:

Wire Harness:

N.O. Switch:

N.O. VL Orifice:

N.C. Switch:

N.C. VL Orifice:

Diff Switch:

Diff VL Orifice:

Igniter:

Burner:

16” Tube:

Ind. Lights:

Diag. Light:

Term. Block:

Transformer:

Fan:

Alt. Fan:

Alt. Fan Usage:

Relay:

Filter:

24 Volt In:

120 Volt In:

Gas In:

Extra VL Orifice:

Production Code:

Version:

Stock:

Add-On:

Internal Use Only:

HEATER

TYPE: Electric:

Tag:

Special 1:

Special 2:

Gas:

Air:

C1

C1 C2 C3

None

N/A

DET3-125

7.08

36G54-224-N

MARK10DX-117

3 PCS Harness

None

None

None

None

IS22010051F5166

Grey (+ / -)

Norton

Mid

4” Gen.

Yellow - 24V

(Specify TP-#’s)

840

851

852

N/A

N/A

264E

50

201B

380

828

On Circuit Board

None

40 VA

Fasco Lg.

50Hz - 120V

When Specified

None

None

3 T-plug

6’ Blk. Cord

7/8” FC

None

N/A

826

55A

55B

N/A

N/A

832

333

83

19

1 5/16”

TP-204#

TP-44#

19

1 7/16”

LLWT038

None

19

1 5/16”

17

1 7/16”

Orifice Type:

SAMPLE

SAMPLE