Contents

1General.........................................4

1.1Introduction..................................4

1.2Deliverycheck.................................4

1.3Customerservice...............................4

2Assembly........................................5

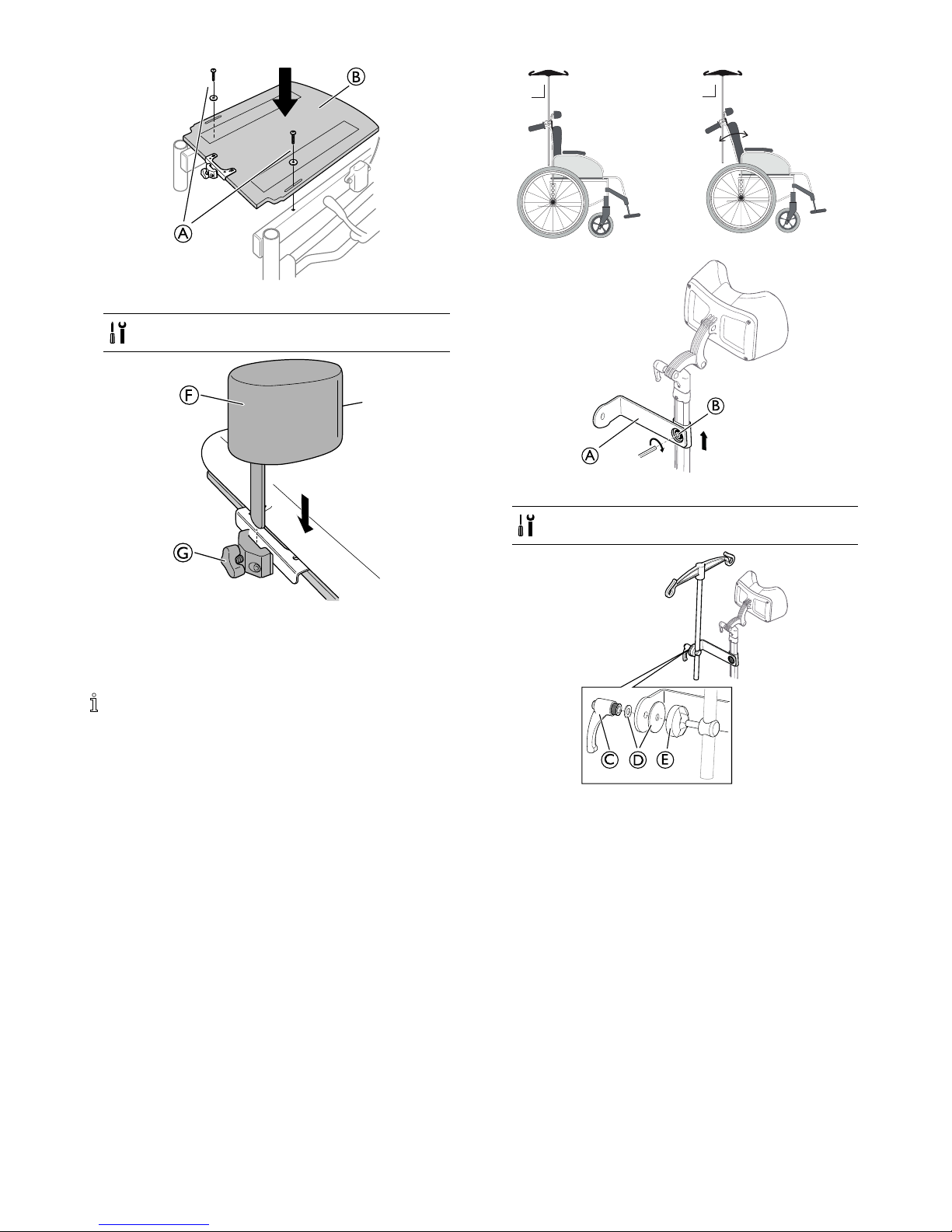

2.1Mountingthetrunksupport......................5

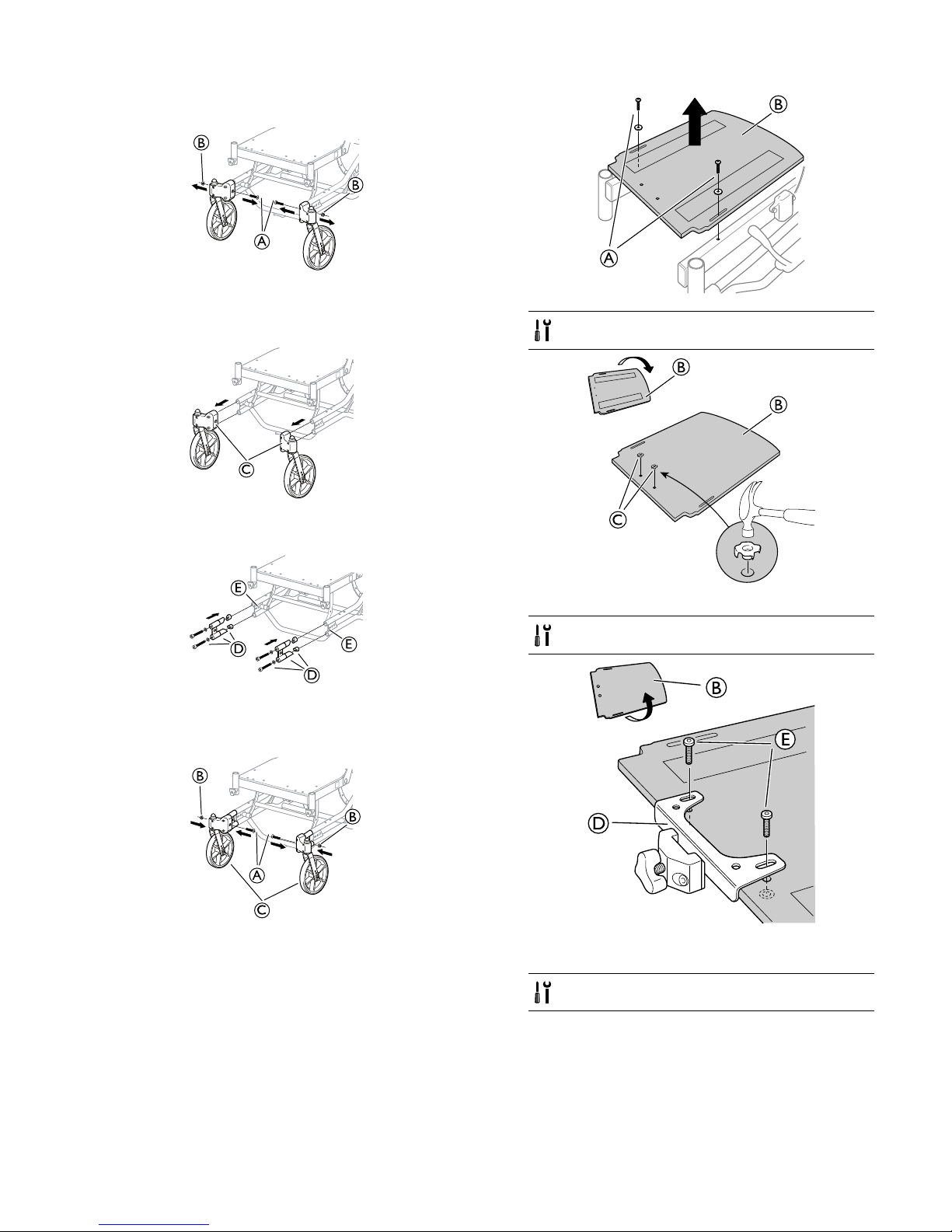

2.2Mountingtheattachmentfortabletray..............5

2.3Mountingthetabletray.........................5

2.4Mountingthehalftray..........................5

2.5Rearwheels..................................6

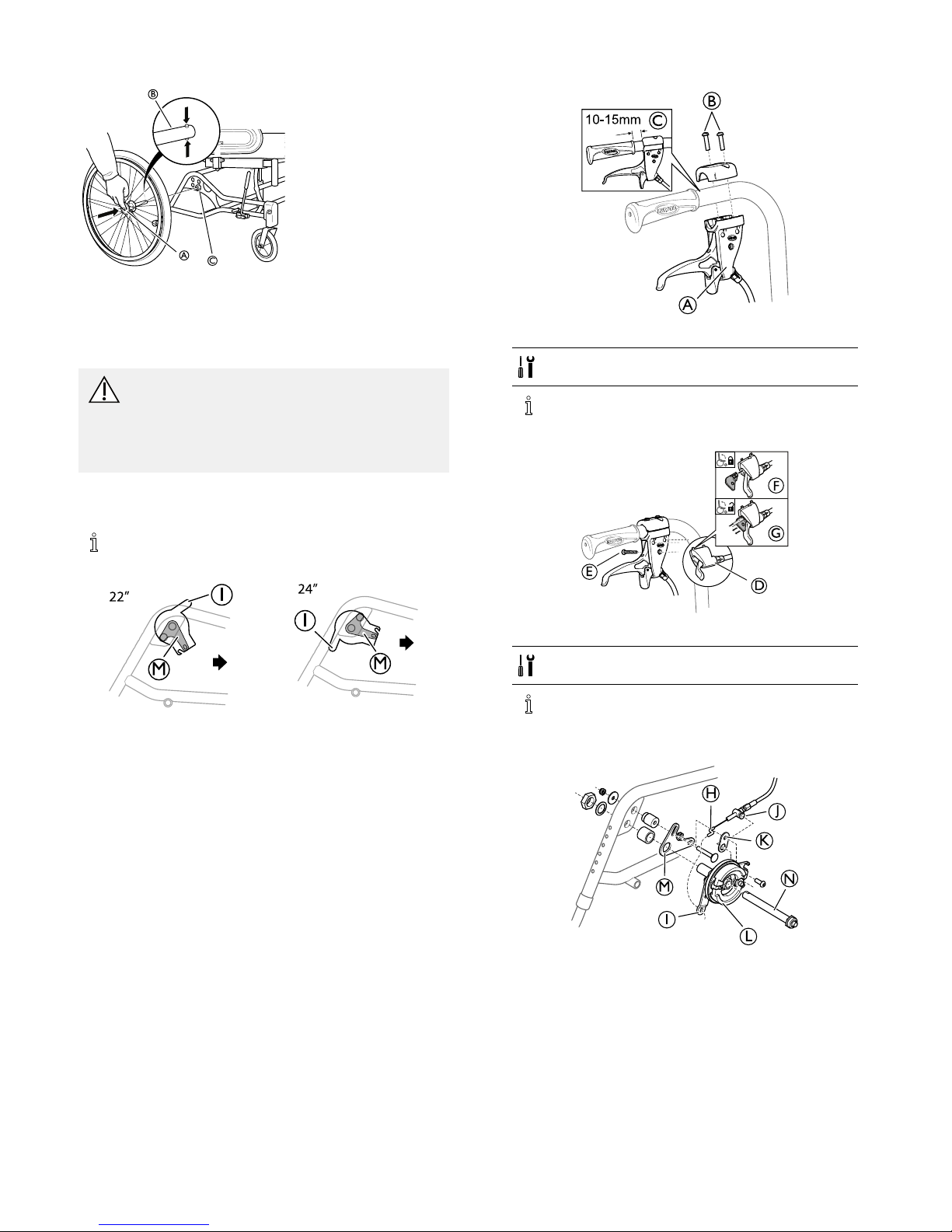

2.6Drumbrakefor22–24”..........................6

2.7Mountingthechassisextender....................7

2.8Mountingthepommel..........................7

2.9MountingtheDripstand.........................8

3SettingsandAdjustments............................9

3.1Positioningtheheadrest/neckresttothefront.........9

3.2Widthadjustment..............................9

3.3Adjustingthecalfpads..........................9

3.4Adjustingthebrakeeffect........................10

3.4.1Userbrake—adjustment......................10

3.4.2Drumbrake—adjustments....................10

4Maintenance.....................................11

4.1Safetyinformation..............................11

4.2Flattire......................................11

4.3Cleaning.....................................11

4.4Washinganddisinfection.........................11

4.5Reconditioning................................11

4.5.1Checklistforreconditioning....................14

5AfterUse........................................15

5.1Recycling.....................................15

5.2Wastedisposal................................15

6T echnicaldata....................................16

6.1Dimensionsandweights.........................16

6.2Material.....................................18

6.3Environmentalconditions........................18

6.4Seatheighttable...............................18