Rearo, Loanbank House, Loanbank Quadrant, Govan, Glasgow, G51 3H

Tel: 0141 440 0800 Fax: 0141 445 3342 www.rearo.co.uk sales@rearo.co.uk

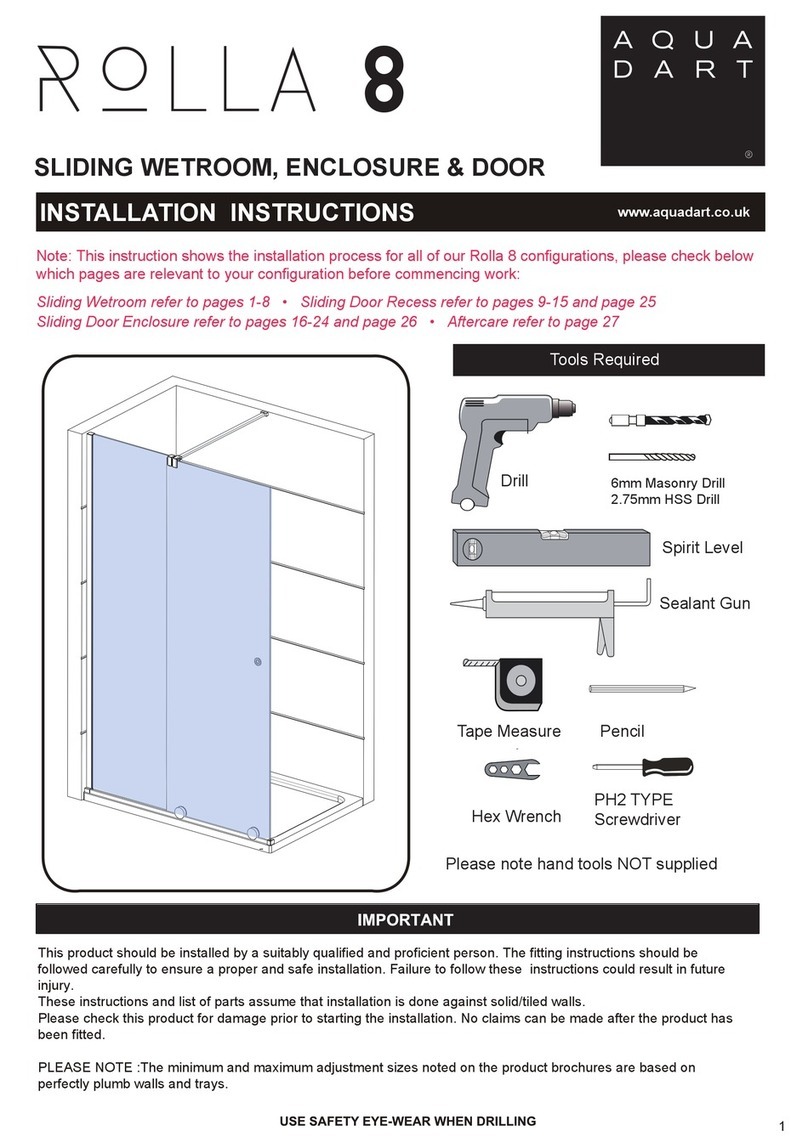

Accessories and Sealants

Important accessories to help with a

successful installation of Selkie Board

include:

Finishing Trims: designed specifically for

Selkie Board are available in satin silver,

polished chrome, white and black including:-

Internal Corner Profile, External Corner

Profile, End Cap,Quad End cap and

'H' section, for vertical application in

heights above 2400mm height.

Sealants and Adhesives: For best results

we recommend that Selkie Board is

installed using an external grade 'high grab

adhesive' such as GRIP FILL. This will

quickly secure the Selkie Board to the fixed

wall. For sealing of all profiles and trims we

recommend the use of a clear silicone

waterproof sealant.

If you are panelling an entire wall using

tongue and grooved* panels, we

recommend the use of Rearo colour

matched sealant for a seamless finish.

*Please see Tongue and Grooved installation guide.

Cleaning

Once installed, Selkie Board requires

minimal maintenance. Selkie Board should

be cleaned with warm water and a

nonabrasive mild detergent.

Scouring products or similar products

should not be used, and doing so may

invalidate your warranty.

FURTHER INFORMATION

For further information please contact your local rearo service centre, where our experienced team can

offer further advice regarding installation or maintenance.

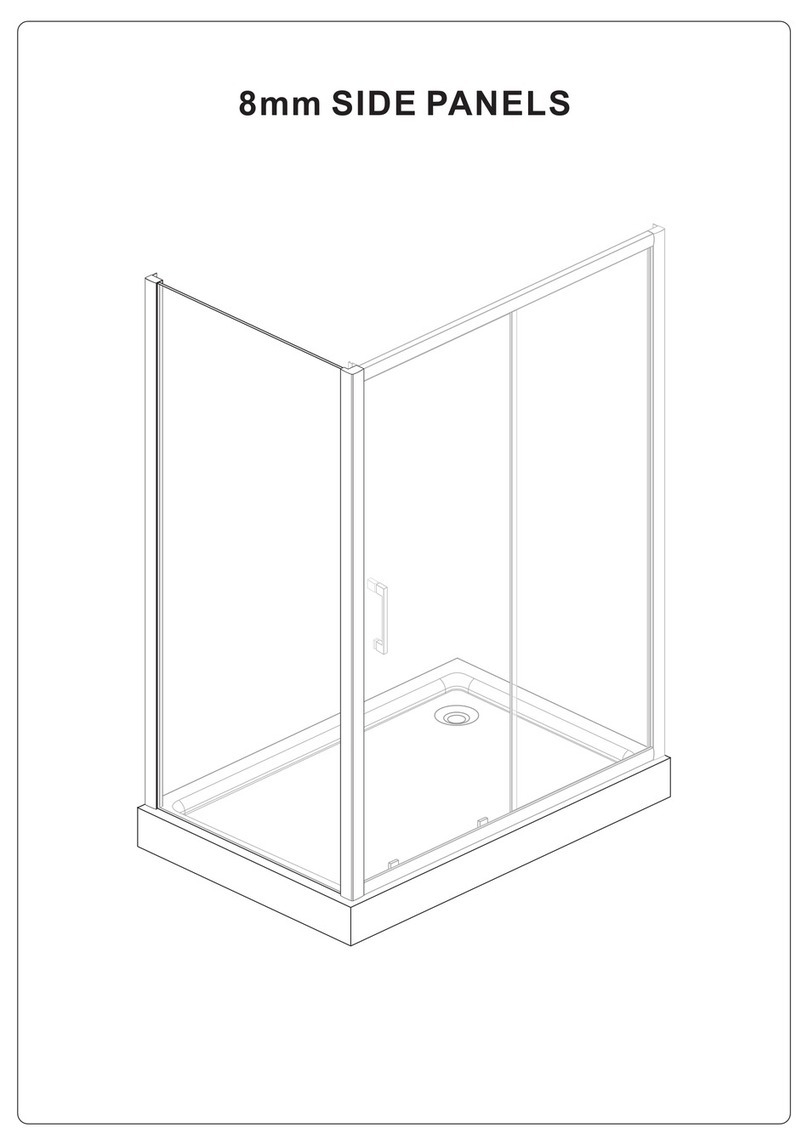

Panseal Kit

Where it is identified that there may be a

risk of movement such as a flexible floor or

the possibility of settlement it maybe

appropriate to use a system such as

“Panseal”. The Panseal kit ensures that

the joint between the bottom of the Selkie

Board and the top of the shower tray is

secure and watertight. (fig 14)

Please see fitting instructions supplied with kit.

Fig14.

Apply Sealant to

areas as shown in

Panseal

instructions

Please be aware that these instructions are not exhaustive, if

you require further information, advice or are in any doubt as

to how to proceed please contact the Rearo technical team

on 0141 440 0800.

Please also note that for all installations there are some

general, simple guidelines which must be followed without

which our warranty would be invalidated including:

• all exposed edges of panels must be sealed.

• panels should never be fitted directly onto a shower tray

without adequate sealing. Please see instructions.

Dec 18

Rearo NORTHAMPTON

5 Rye Hill Close

Britannia Trade Park,

Northampton

NN5 7UA

T: 01604 212559

F:

E: northampton@rearo.co.uk

Rearo SHETLAND

taneyhill Gas Depot

North Road

Lerwick

hetland Isles

ZE1 0QA

T: 01595 692807

F: 01595 695469

E: lerwick@rearo.co.uk

Rearo ROSYTH

Unit 15 & 16 Primrose Lane

Dunfermline Business Park

Rosyth

KY11 2RN

T: 01383 414000

F: 01383 414400

E: rosyth@rearo.co.uk

Rearo WASHINGTON

Unit 15, Tilley Road

Crowther Industrial Estate

Washington

Tyne & Wear NE38 0AE

T: 0191 482 2298

F: 0191 482 6245

E: washington@rearo.co.uk

Rearo Selkie Install 51218 .qx _Layout 1 11/01/2019 14:48 Page 1