10mm

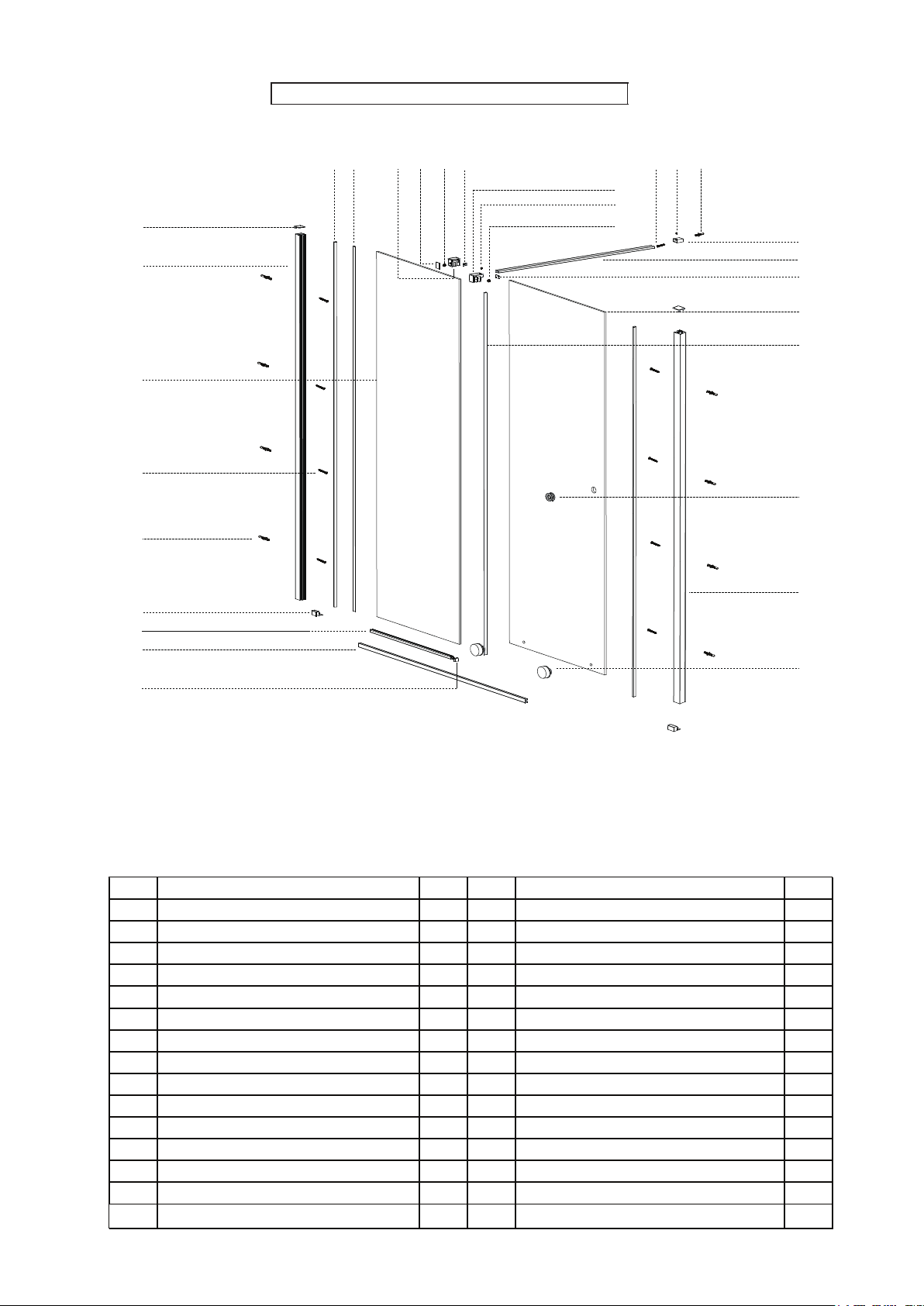

Door panel

Fixed panel

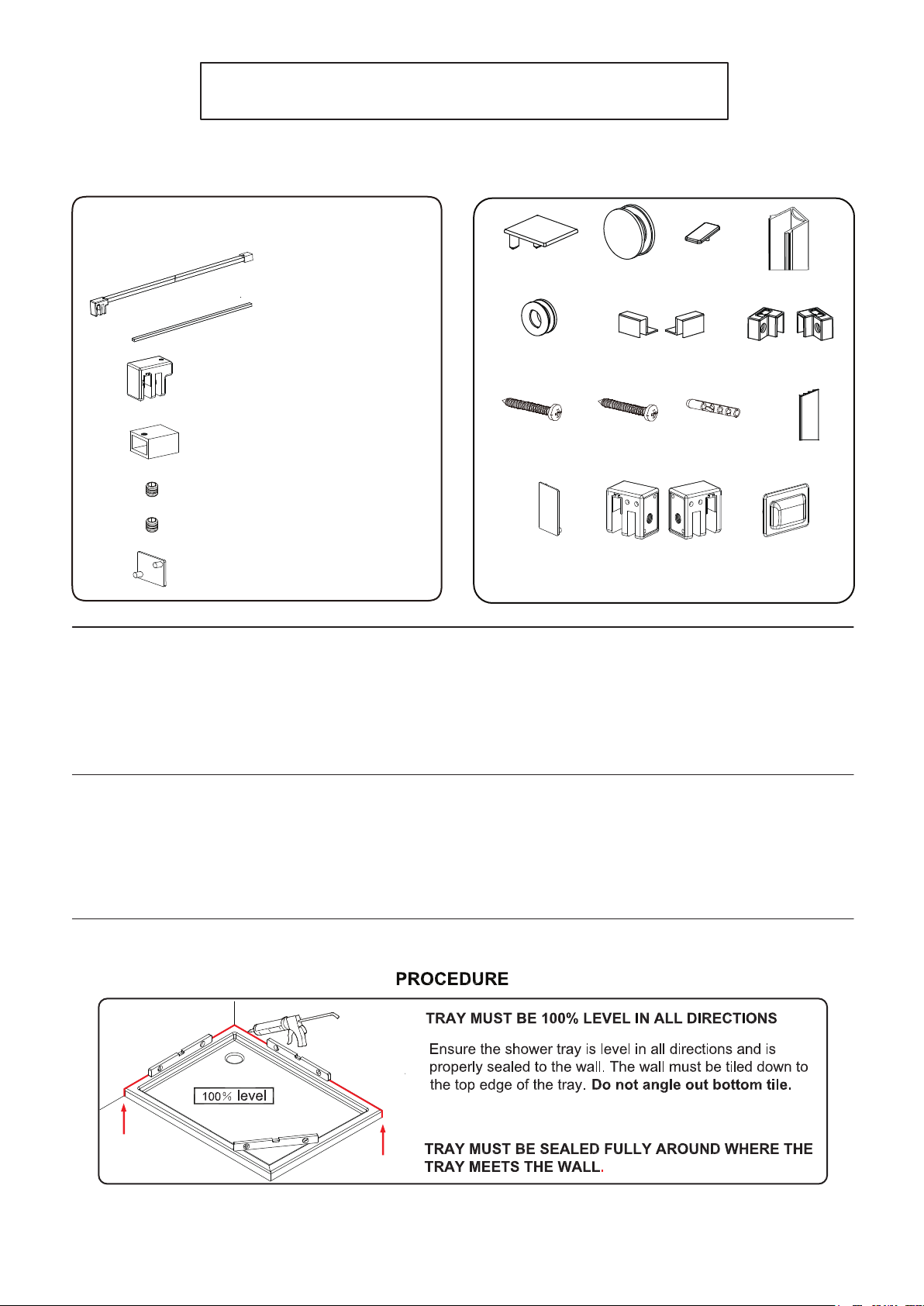

3.6

Step 3.6 Ensure the glass clamp is in about 10mm away from the fixed panel edge(Diagram 3.6) then attach it onto the

fixed panel using M10 x6 grub screw(Part 27)

Step 3.7 Fit the support arm wall fixing onto the support arm bar and place it onto the wall in required position.Measure

the dimension from the glass clamp to the wall fixing to get dimension Y.Cut the support arm to the required length

X according to the formula X=(L-Y)+25mm(L is the original length of the support arm bar,1057mm)

3.7

Step 3.8 Fit the support arm wall fixing onto the support arm bar before inserting the support arm bar onto the glass clamp,

move the wall fixing to the wall and level the support arm bar, mark the postion of the wall fixing onto the wall.Drill

through the marked position on the wall using a 6mm masonry drill bit and insert the wall plug(part 24).Fix the

wall fixing onto the wall using screw ST 4X30(Diagram 3.8).

Insert the support arm bar to the wall fixing,pull the bar out from the wall fixing to insert into the glass clamp, then

secure the support arm bar together with the glass clamp and wall fixing using M5 x6 grub screws.

3.8

Step 3.9

3.9

3.9

3.9

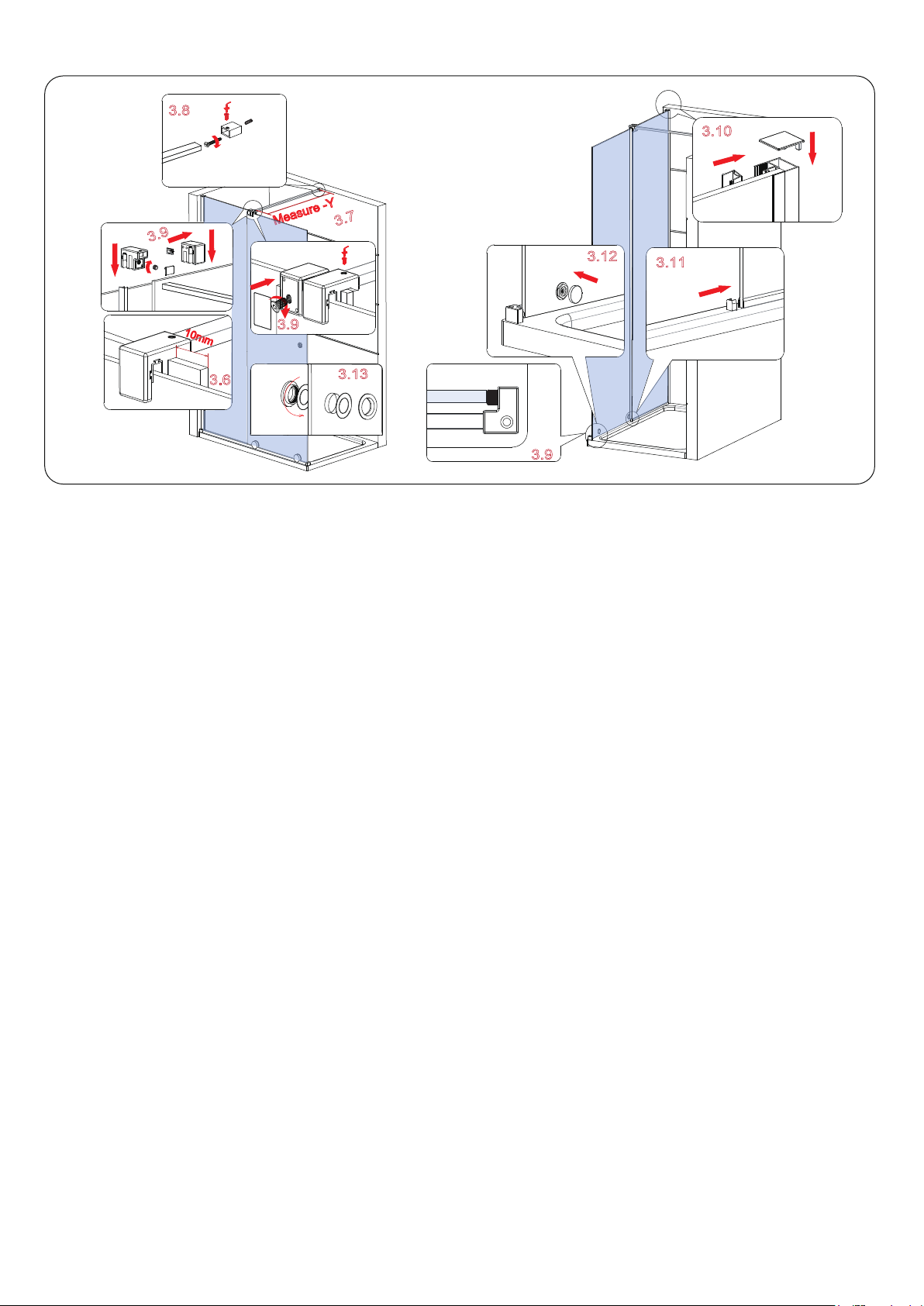

Step 3.10 Press the closing bubble seal (Part 5) into the wall profile channel, then fit the wall profile top cap(part 1) onto the

wall profile(part 2)

Fit a soft head (part 28) onto the roller stopper (part 31),then slide the door panel to ensure it touches the soft

head on the bottom rail end fixing (Diagram 3.9), fit the roller stopper onto the door panel, ensure the soft head

on the roller stopper touches the glass clamp then secure the roller stopper onto the door panel using M10x6

grub screw (Diagram 3.9).

Door panel

3.10

3.11

3.12

3.13

Step 3.11 Fit the bottom strip end cap(part 13) onto the bottom strip.(Diagram 3.11)

Step 3.12 Press the roller screw cap to cover the screws (Diagram 3.12).

Step 3.13 Fit the ring handle(part 20) onto the door panel. (Diagram 3.13).

Step 3.14 Fit the cover cap onto the roller stopper and glass clamp.

7