Version Number: RBM-1350 20210712A2

Note:

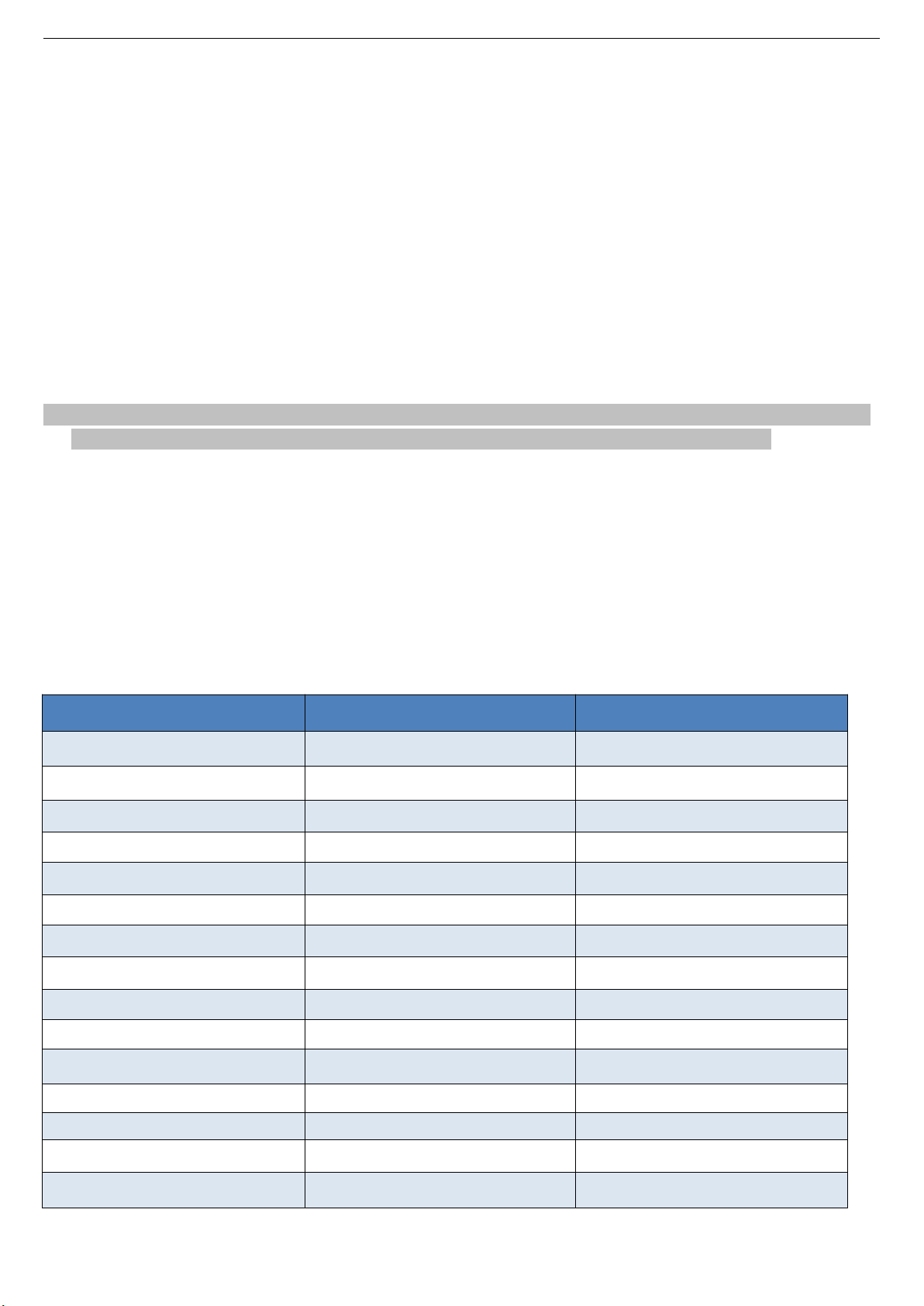

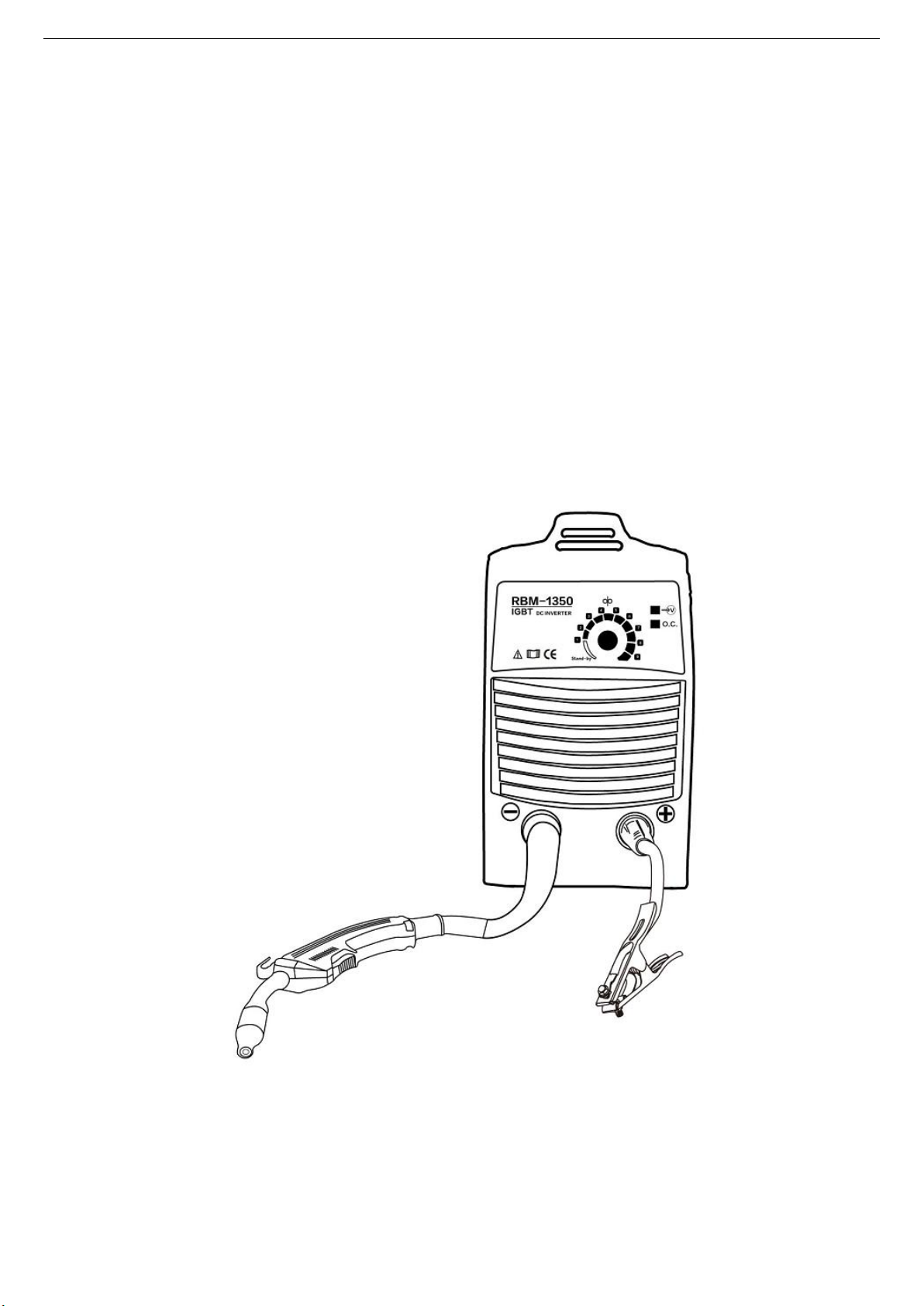

1) Please strictly follow the picture instructions to connect, otherwise it will not be possible to solder.

2) The flux-cored welding wire supports 0.8mm, 0.9mm.

3) The machine can install 1kg(2.2lb) welding wire reels.

4) The machine is equipped with a 1kg(2.2lb) flux cored wire, which can be directly installed and used.

5) Support welding material: carbon steel(Note: Aluminum and stainless steel cannot be welded.)

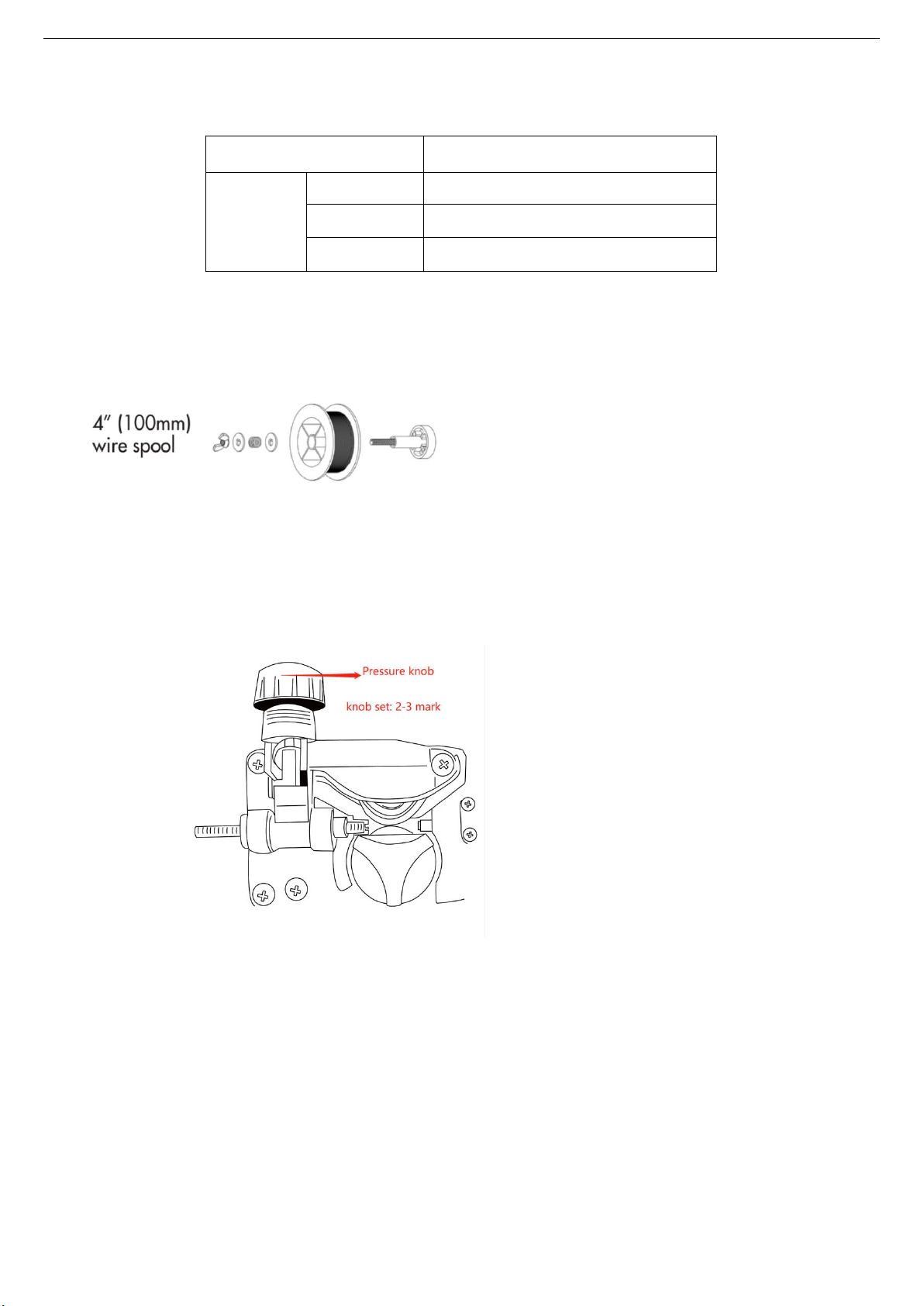

6) The diameter of the welding wire, the groove of the wire feed wheel and the aperture of the contact tip must

match.

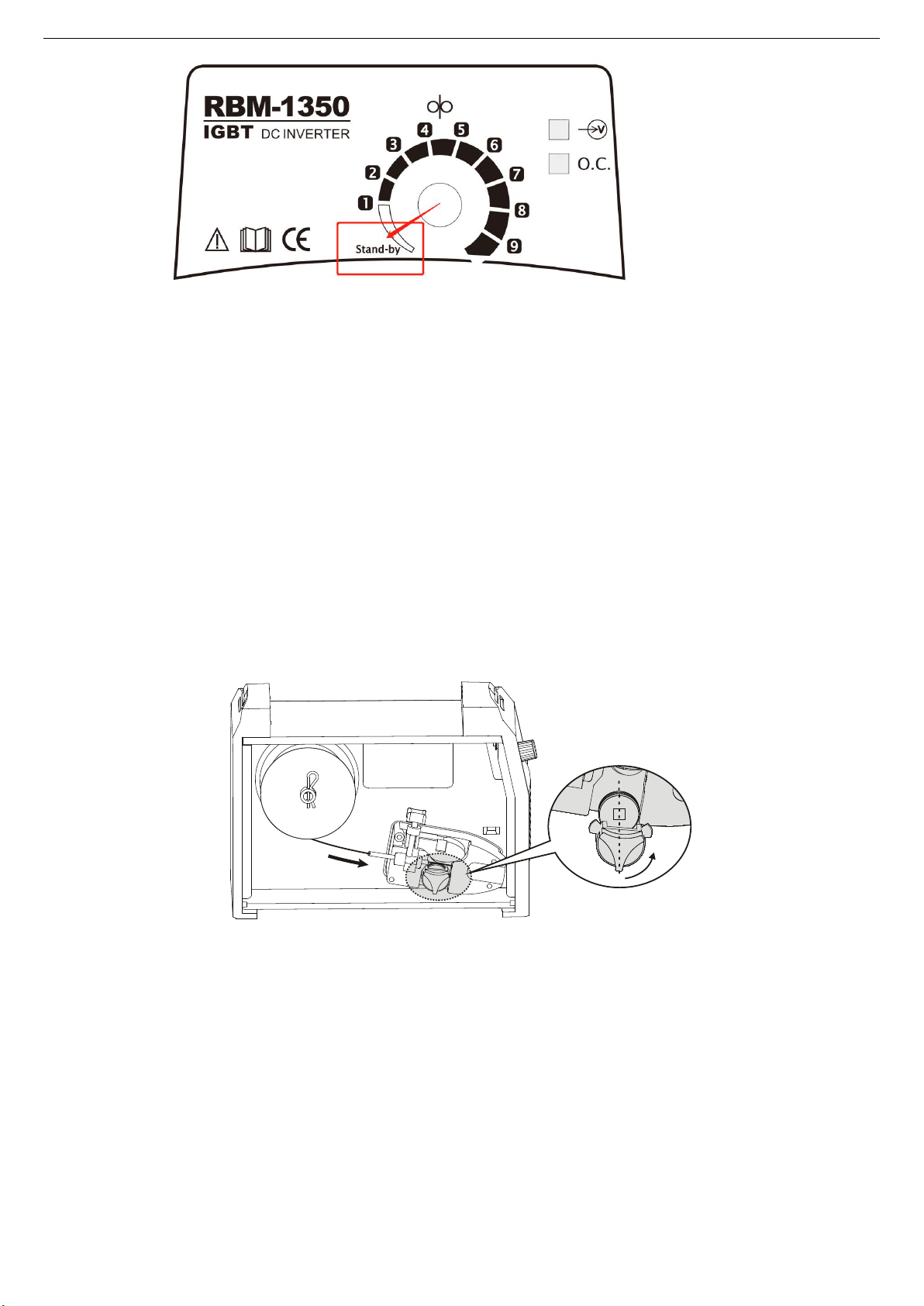

7) The pressure roller of the wire feeding structure should not be too tight or too loose, which will cause the

wire feeding to be unstable.

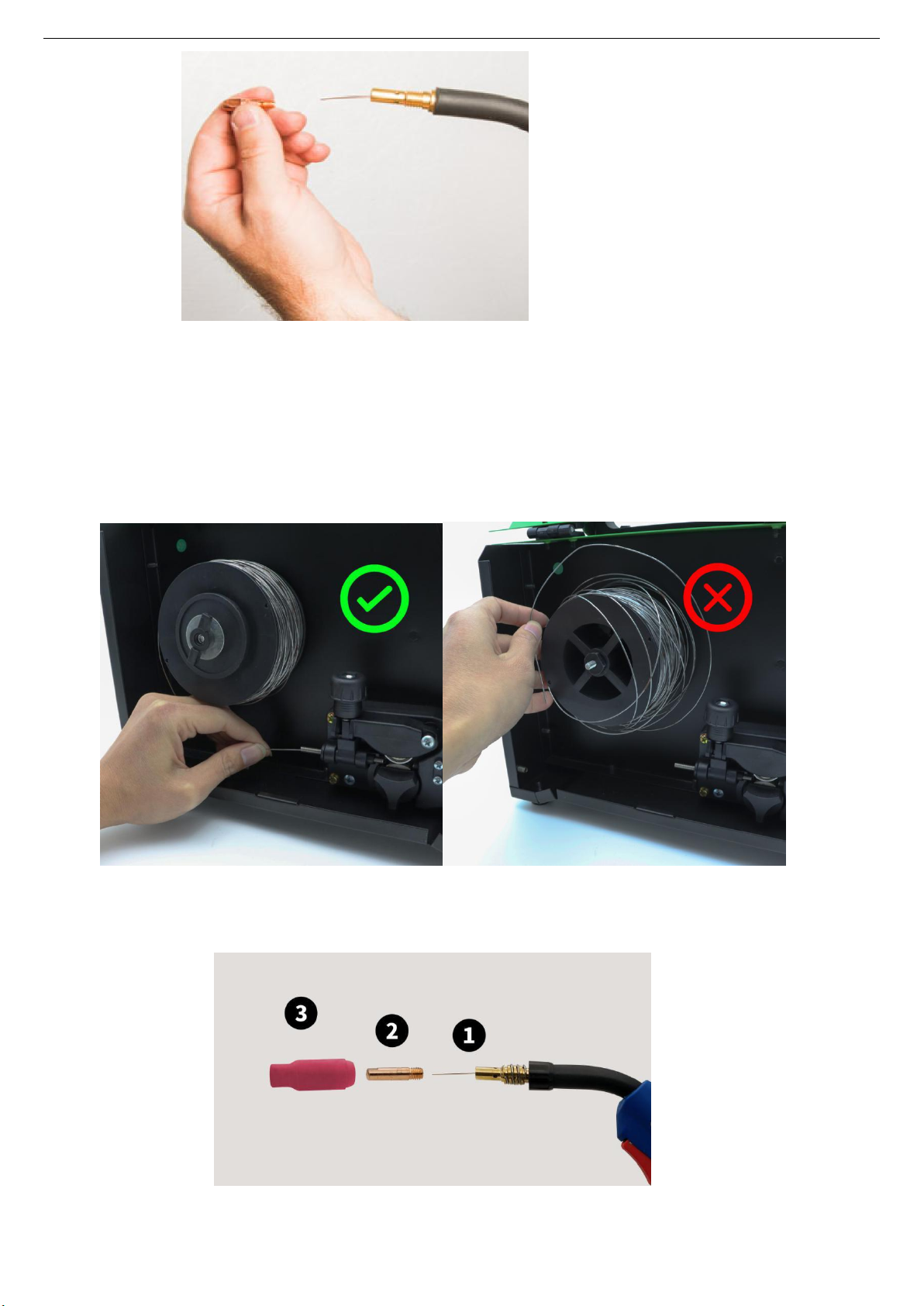

8) The installation of the wire feed reel should not be too loose or too tight, which will cause the welding wire of

the wire reel to spring off and the wire feeding too slow.

Possible problems

1) There is no response when turning on the power, please check the plug connection.

2) There is no response when turning on the power, please open the cover and check whether the internal

connecting wires are loose.

3) The wire feeding is unstable. Please check the wire feeding reel and the wire feeding pressure roller, and the

welding gun should not be wound. Pay attention that the diameter of the welding wire matches the wire

feeding wheel groove and contact tip.

4) No wire feeding, please confirm that the welding gun is connected well, press the gun switch or no wire

feeding, please contact us.

5) During the welding process, if the time exceeds 3 minutes, over-current protection may occur. You need to

stop working for a few minutes, let the machine cool for a period of time, and automatically recover. If the air

cools for more than 10 minutes, the machine does not automatically recover, please shut down and restart.

6) If you have any questions, please contact us .

3.10 Welding environment and safety

Working surrounding

a) Welding should be carried out in dry surroundings. The air humidity level should not be higher than 90%.

b) The temperature should be between -10C to 40C.

c) Don’t use the welding machines in sunshine or rain. Keep it off water.

d) Don't use the machines in the places of dust or corrosive air.

Safety norms

Protection circuit of over-voltage, over-current and over-heat circuits are designed in the welding machines.

It will stop working automatically when the input voltage, output current or internal temperature exceed the

rated value. But if the machines are excessively used, such as with input voltage higher than the rated, the

machine might be damage. Please pay close attention to the following matters.

a) Keep good ventilation!

The welding machines work with high welding current. Nature air flow can’t reach the requirement of heat

dissipation. So the fans are installed as cooling system to ensure stable performance.

Make sure the ventilation windows are not covered or blocked. The distance between the machines and