Version Number: RBT200P/ACDC-20210702A2

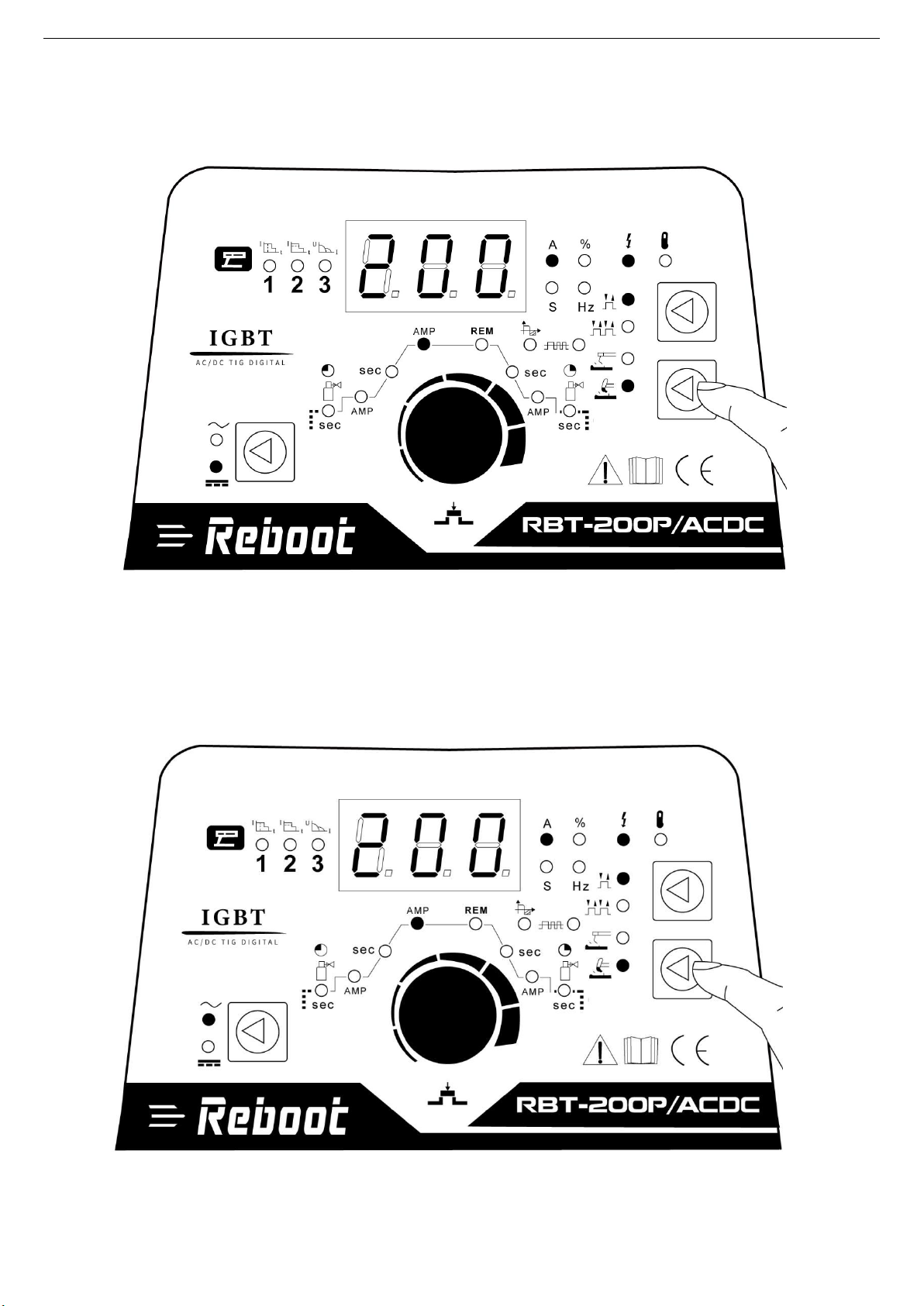

1.3 To adjust the current, only the current can be adjusted.

1. Hot Start Function reliably ignites the electrode and melts perfectly to ensure the best quality

even at the start of the seam. this solution makes lack of fusion and cold welds a thing of the past

and significantly reduces weld reinforcement. Adjust the hot start current here and the time here.

2. Arcforce Correction During the welding process, arcforce prevents the electrode sticking in the weld pool with

increases in current. this makes it easier to weld large-drop melting electrode types at low current strengths with

a short arc in particular

3. Anti-stick prevents the electrode from annealing. If the electrode sticks in spite of the arcrorce device, the

machine automatically switches over to the minimum current within about 1 second to prevent the electrode

from overheating. In order to easily separate the electrode and electrode holder to protect the welder.

Note:

1) The welding rod specification supported by Reboot RBT-200PD/ACDC is below 4.0(5/32in), usually 2.5(3/32in)

and 3.2(1/8in). European style generally uses E6013, American style generally uses E7018, and stainless

steel generally uses ER308.

2) It supports welding of 1-8mm(1/64-5/64in) carbon steel and 1-5mm(1/64-7/32in) stainless steel. Aluminum

can not be welded. For carbon steel, please use carbon steel electrode. For stainless steel, please use

stainless steel electrode.

3) Connect the ground clamp to clean bare metal. No rust, paint or other coatings, and ensure good electrical

conductivity.

4) The ideal distance between the welding rod and the welding object is 1-2mm(1/64-5/64in), to ensure that the

welding rod and the workpiece are in continuous and stable contact. The welding rod should not be too high

or pressed too low to avoid arc breaking and adhesion.

5) It is normal for novices to have adhesion during the welding process, and you can try to friction arc to avoid

adhesion.

6) Suitable for ordinary welding rods, such as 7018, 6013, etc., but not suitable for special welding rods, such as

7010, 7011.

Possible problems

1) There is no arc, check the ground wire to connect the workpiece to ensure that there is no rust, paint or other

coatings on the workpiece.