Installation.......................................................................................................................Section A

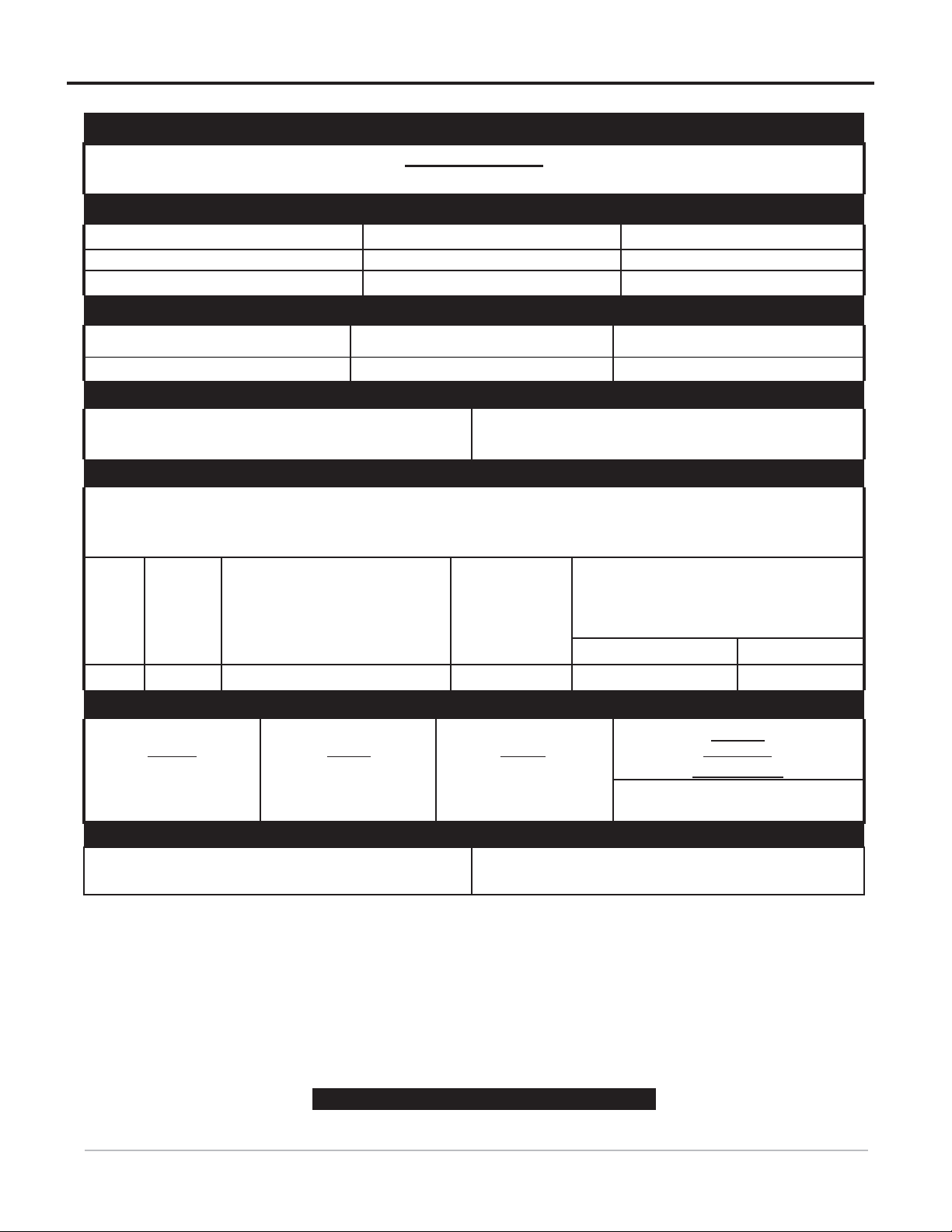

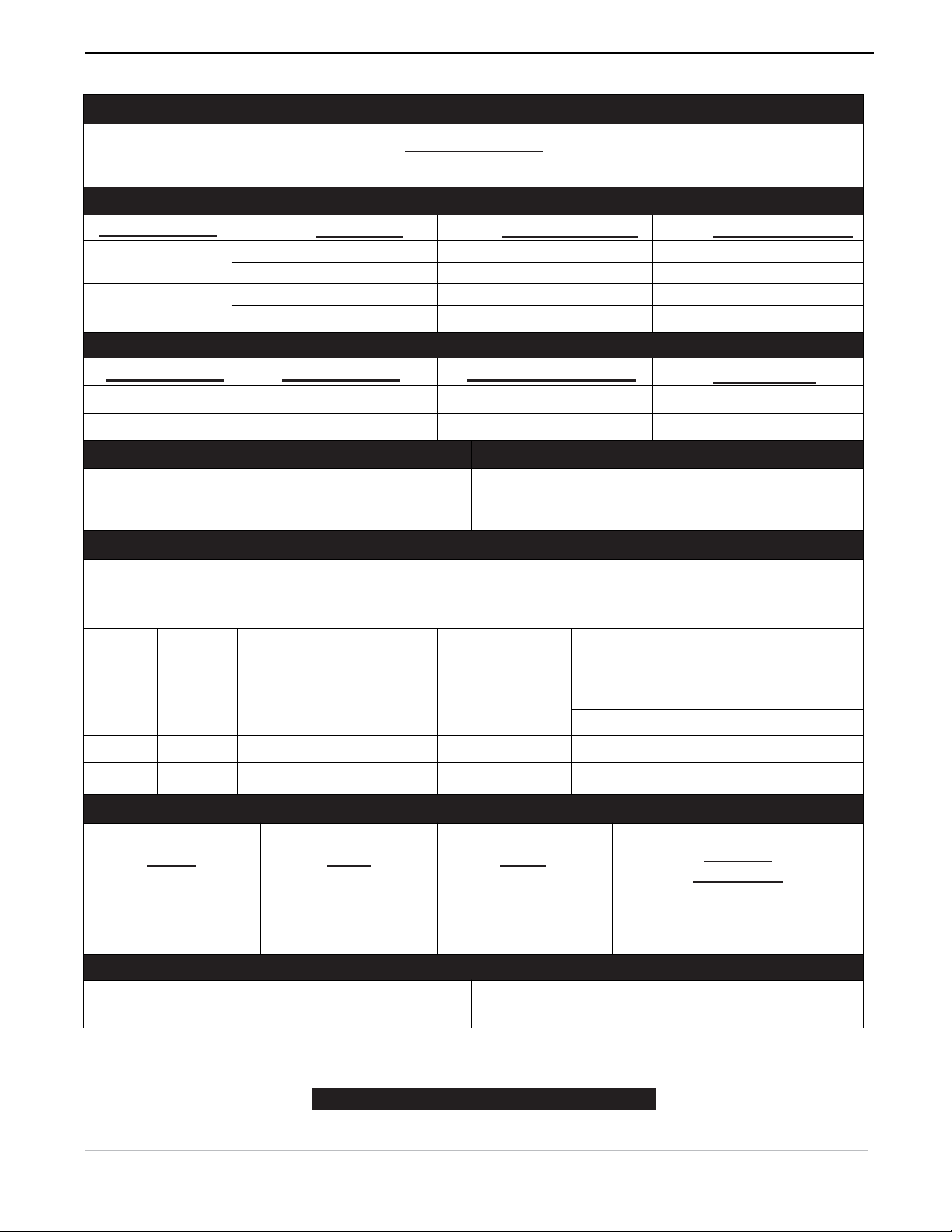

Technical SpecificationsC ut 40 (11 0 V ).................................................................................A-1

Technical SpecificationsC ut 40 (22 0 V )................................................................................A-2

Technical SpecificationsRBC 5000........................................................................................A-3

Technical SpecificationsRBC 5000 D....................................................................................A-4

Technical SpecificationsRBC 5000 D L ................................................................................A-5

Safety Precautions ..................................................................................................................A-6

Select Proper Location ..........................................................................................................A-6

Stacking................................................................................................................................A-6

Tilting.......................................................................................................................................A-6

High Frequency Interference Protection...............................................................................A-6

Input Electrical Connections.................................................................................................A-6

Gas Input Connections...........................................................................................................A-7

Output Connections................................................................................................................A-7

Torch ................................................................................................................................A-7

Compressor .....................................................................................................................A-7

Operation.........................................................................................................................Section B

Safety Precautions ...............................................................................................................B-1

Description............................................................................................................................B-1

Preheat Temperature for Plasma Cutting..........................................................................B-1

User Responsibility...............................................................................................................B-2

Design Features and Advantages ......................................................................................B-2

Cutting Capability .................................................................................................................B-2

Consumable Life ..................................................................................................................B-2

Installation Diagram ....................................................................................................... B-3,B-4

How to installation of the air compressor...............................................................................B-4

ControlsandSettings..........................................................................................................B-5

Cutting Process ................................................................................................................... B-6

Torch ....................................................................................................................................B-7

Pilot Arc Discussion For RBC5000DL..................................................................................B-7

Procedure Recommendations..............................................................................................B-7

General .........................................................................................................................B-7

Suggestions for Extra Utility from the Machine System ..............................................B-8

Torch Part Configurations ....................................................................................................B-9

Accessories .....................................................................................................Section C

Maintenance ....................................................................................................Section D

Safety Precautions ................................................................................................D-1

Routine Maintenance.............................................................................................D-1

Periodic Maintenance ............................................................................................D-1

Troubleshooting ..............................................................................................Section E

Safety Precautions.................................................................................................E-1

How to Use Troubleshooting Guide.......................................................................E-1

Error Signals ............................................................................................................E-2

Troubleshooting Guide ..............................................................................E-3 Thru E-6

..............................................................................................................................Appendix