Page | 3

V1.02

1. Introduction

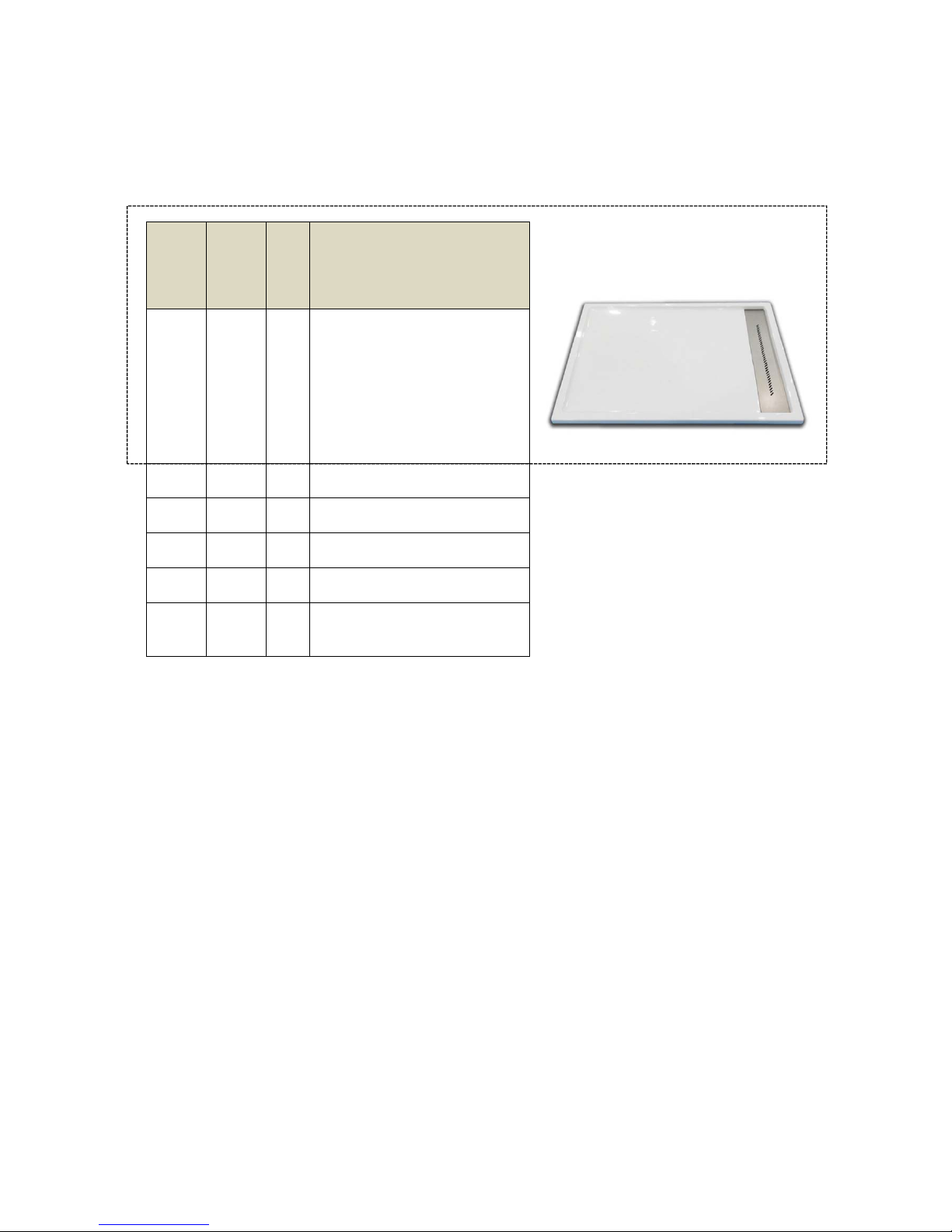

The RECOUP Tray+ DSS-S2 (1200mm) is a Waste Water Heat Recovery Unit (WWHRU) for shower

water, meaning it recovers heat from the warm waste water as it passes through before going to the

drainage system for the property.

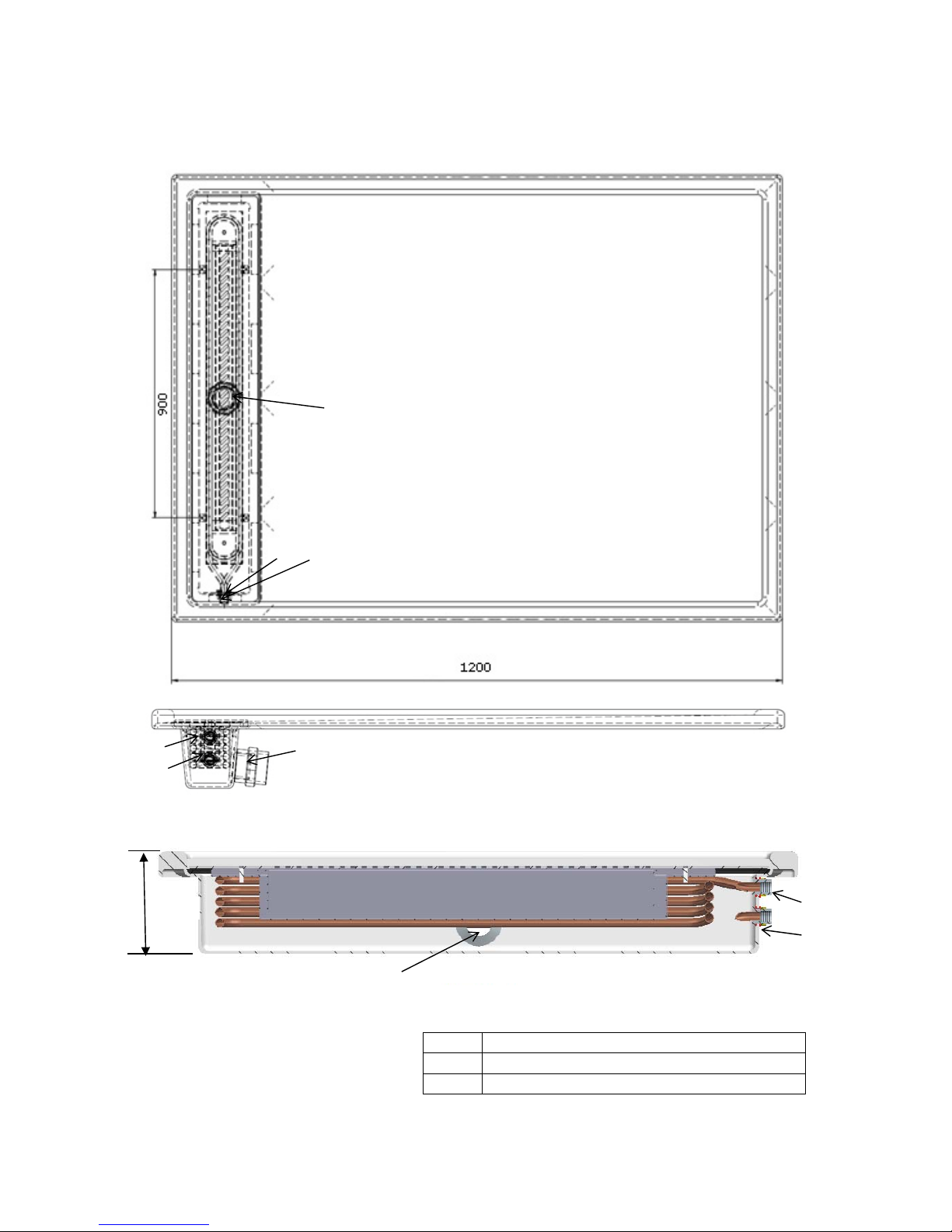

The heat recovery is possible, due to the copper heat exchanger within the Tray+ DSS-S2 (1200mm)

which is a very effective material for transferring heat. This preheated water then supplies the mains

cold feed to the shower and either a combination boiler or a hot water storage cylinder.

The reason for doing this is to save money and energy. In an average shower the water will come out

of the shower head at 40°C, and the water going down the drain will only be a few degrees cooler

than this. This energy has been paid for once, and we believe at Recoup Energy Solutions, that the

home owner should get as much benefit from this energy before paying to reheat more water and at

the same time reduce the energy consumption and CO2 emissions of the home.

The RECOUP Tray+ DSS-S2 (1200mm) should be installed by a suitably qualified plumber who gives

consideration and attention to the system design as well as a correct installation.

The RECOUP Tray+ DSS-S2 (1200mm) is a horizontal heat exchanger and it is very important to

follow all the instructions for installation of the RECOUP Tray+ DSS-S2 (1200mm) for the product to

perform successfully.

IMPORTANT – For recognition of the RECOUP Tray+ DSS-S2 (1200mm) energy saving performance

within the National Calculation Method (NCM) for the energy rating of a new build dwelling within

the UK, using the Standard Assessment Procedure (SAP) it is vital that the following are complied

with: -

a) This Instruction Manual

b) A system design checklist

c) Installation checklist

d) Certificate of installation

b, c & d are supplied as a single document and are attached with this document and also available

at: www.sap-appendixq.org.uk – A signed copy of each should: -

1. Be left with the home user pack (for the home owner)

2. Retained by the installer

3. A copy sent to RECOUP Energy Solutions Ltd (See company details on Page 10).

(Note: Building control officers may also request a copy)

A NCM (SAP) identifier label should be permanently fixed to the RECOUP Tray+ DSS-S2 (1200mm)

unit and a second label attached to a nearby boiler or service cupboard. The ‘model qualifier’ section

of the first label denotes the system installation configuration (A, B or C) and will state ‘Refer to

Installation certificate otherwise System B will be assumed. The actual system configuration will be

recorded on the system design checklist, installation checklist/certificate of installation and the

second NCM (SAP) identifier label.