RED LABEL RLATJ20T User manual

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications

Visit us at www.tqbbrands.com.au

OWNER’S MANUAL

PRODUCT CODE: RLATJ20T

20,000kg AIR ACTUATED GARAGE JACK

Lifting

Capacity

Adjustment

Height

Maximum

Height

Minimum

Height

Nett Weight

Package Size

20,000kg

80mm

465mm

210mm

40kg

660x360x280mm

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 2

Visit us at www.tqbbrands.com.au

WARNING

IMPORTANT: READ ALL INSTRUCTIONS BEFORE USE

WARNING

The instructions and warnings contained in this manual should be read and understood before

using or operating this equipment. Do not allow anyone to use or operate this equipment until

they have read this manual and have developed a thorough understanding of how this

equipment works. Failure to observe any of the instructions contained in the manual could

result in severe personal injury to the user or bystanders, or cause damage to the equipment

and property. Keep this manual in a convenient and safe place for future reference.

Whilst every effort has been made to ensure accuracy of information contained in this manual,

the TQB Brands Pty Ltd policy of continuous improvement determines the right to make

modifications without prior warning.

CONTENT

WARNING .............................................................................................................................. 2

CONTENT ............................................................................................................................... 2

SAFETY INSTRUCTIONS ........................................................................................................... 3

ASSEMBLY, OPERATION, PREVENTITIVE MAINTENANCE .......................................................... 4

TROUBLESHOOTING ............................................................................................................. 14

PARTS LIST ........................................................................................................................... 16

WARRANTY .......................................................................................................................... 18

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 3

Visit us at www.tqbbrands.com.au

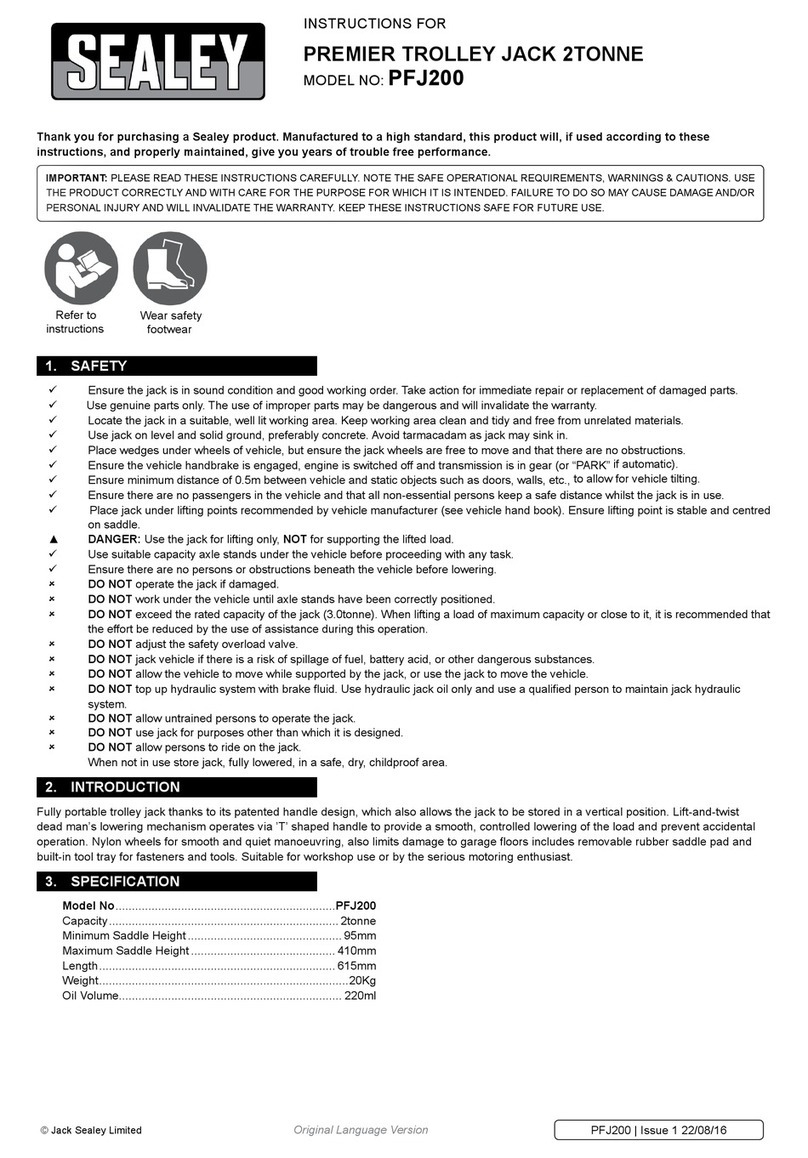

SAFETY INSTRUCTIONS

WARNING

FAILURE TO READ THESE WARNINGS MAY RESULT IN PROPERTY DAMAGE & PERSONAL

INJURY

• Support load by appropriate means after

lifting

• Do not exceed the jacks rated capacity

• Centre load on the jack

• Only use attachments and/or adapters

supplied with or sold specifically for the

jack

• Only lift areas of the vehicle designated by

the vehicle manufacturer.

• Use as lifting a device only

• Use only on hard, level surfaces

• Do not modify this jack

SAFETY OPERATING INSTRUCTIONS

• This Jack should be used for lifting and lowering only. The raised vehicle should be

supported on approved vehicle stands. No person should get any part of the body

under a vehicle that is supported by this jack.

• Position the jack to only lift on the areas of the vehicle specified by the vehicle

manufacturer.

• Use support stands – after lifting the vehicle always support the load with

appropriately rated vehicle support stands before working on the vehicle.

• Do not overload this jack beyond its rated capacity. Overloading this jack beyond its

rated capacity can cause damage to or failure of the jack.

• Use only on hard level surfaces capable of sustaining the load. Use on other than

hard level surfaces can result in jack instability and possible loss of load.

• Centre load on jack saddle before lifting vehicle.

• Do not move or dolly the vehicle while on the jack.

• Off centre loads and loads lifted when the jack is not level can cause loss of load or

damage to the jack.

• Keep hands & feet clear of the jack hinge mechanism & ground contact area when

lowering the load.

• Always wear safety glasses and/or other protective clothing.

THIS JACK IS A LIFTING DEVICE ONLY & IS DESIGNED FOR LIFTING PART OF THE TOTAL

VEHICLE. DO NOT MOVE OR DOLLY THE VEHICLE WHILST THE VEHICLE IS ON THE JACK.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 4

Visit us at www.tqbbrands.com.au

ASSEMBLY, OPERATION, PREVENTITIVE MAINTENANCE

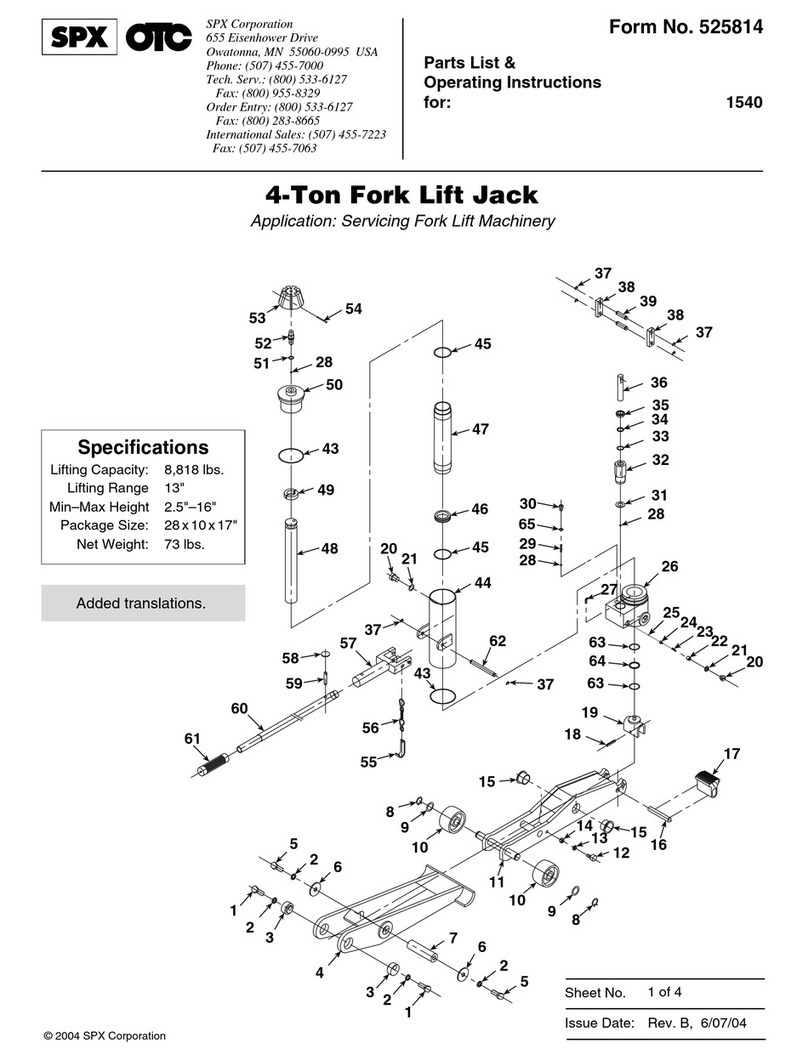

1. FEATURES

The Red Label air-actuated 20,000kg Garage Jack has a powerful air motor to lift heavy

loads. The compact design easily fits between dual tandem axles. Ideal for lifting axles,

farm vehicles, heavy-duty machinery, industrial equipment and more.

2. ASSEMBLY

All numbers refer to the index from the parts breakdown.

1. Familiarise yourself with the jack.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 5

Visit us at www.tqbbrands.com.au

2. Refer to picture when performing this step. Take off the screw located on handle

piece 1; attach handle pieces 1 and 2 making sure to align the holes on both sections.

Reinsert the screw and tighten. Check that handle is in perfect alignment with

internal lowering valve mechanism. (Handle lowering mechanism must be in perfect

alignment or release mechanism will not work.)

3. Attach handle position release rod.

4. Check movement of both pieces before next step.

5. Insert the handle (37) into handle sleeve (45) and affix the handle (37) using bolt

(46).

4-4-2

4-8

4-4-1

4-9-1

4-9-2

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 6

Visit us at www.tqbbrands.com.au

3. BEFORE USE

Prior to each use conduct a visual inspection checking for abnormal conditions, such as

cracked welds, leaks, and damaged, loose, or missing parts.

• Consult the vehicle owner’s manual to determine the location of lift points.

• Be sure to set the vehicle in park with the emergency brake on and wheels securely

chocked.

• Be sure that the vehicle and the jack are on a hard, level surface.

System Air Purge Procedure: Perform the following Air Purge Procedure to remove any

air that may have been introduced into the hydraulic system as a result of product

shipment and handling. This step is to be completed without any weight on the jack.

1. Connect air supply inlet to source.

2. Close the release valve by turning the handle knob clockwise until firm

resistance is felt.

3. Squeeze air trigger to raise saddle. When the

saddle reaches maximum lift height, open the

release valve by turning the handle knob counter-

clockwise.

2

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 7

Visit us at www.tqbbrands.com.au

4. When the saddle reaches minimum lift height, use a flat blade screwdriver to

push the oil filler plug slightly to the side to purge trapped air from system.

5. Close the release valve by turning the handle knob

clockwise until firm resistance if felt.

6. Jack is now ready for use. Check for proper pump action.

7. Pour a teaspoon of good quality, air tool

lubricant into the air supply inlet of the lift

control valve. (See illustration). Connect to

air supply and operate for 3 seconds to

evenly distribute lubricant.

8. Check that the pump operates

smoothly before putting into service.

9. This product is fitted with a ¼ “ air

fitting. If it does not suit your air

supply please ensure you use thread

tape or compound to seal connection

of suitable fitting.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 8

Visit us at www.tqbbrands.com.au

4. OPERATION

4.1. Raising the Jack

Note: The jack is equipped with a handle position lock. To adjust the handle, release

lock device by pulling the lever up, lever is spring loaded and will lock into desired

position. Ensure lever locking mechanism is fully engaged before leaving.

1. Block the vehicle’s wheels for lifting stability. Secure the load to prevent

inadvertent shifting and movement

2. Position the jack near desired lift point.

3. Set the Parking Brake in the vehicle.

4. Refer to the vehicle manufacture owner’s manual to locate approved lifting

points on the vehicle. Position the jack so that the saddle is centred and

will contact the load lifting point firmly.

5. Select desired position for the handle; ensure that spring clips align with

slots.

6. Connect air source to the air supply inlet (2).

7. Close the release valve by turning the handle knob

clockwise until firm resistance is felt.

2

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 9

Visit us at www.tqbbrands.com.au

8. Before raising the vehicle double check and verify the saddle is centred and

also has full contact with the lifting point.

9. Squeeze air trigger to lift until saddle contacts

load. (To stop air operation, simply release the

grip on the lift control valve.) Continue to pump

the jack to lift the vehicle to the desired height.

10. After lifting, support the load with appropriately rated vehicle support

stands before working on the vehicle.

4.2. Lowering the Jack

1. Raise load high enough to allow clearance for the jack stands to be

removed, then carefully remove jack stands.

2. Grasp the handle firmly. Securely hold on to the jack

handle so your hands do not slip and ensure the release

valve does not rapidly lower.

3. Carefully open the release valve by slowly turning the

handle counter clockwise. (Do not allow bystanders

around the jack or under the load when lowering the

jack).

4. After removing the jack from under the vehicle,

fully retract the jack to reduce ram exposure to

rust and contamination. Push the ram and handle

sleeve down to reduce exposure to rust and

contamination.

WARNING: USE EXTREME CAUTION WHEN LOWERING THE JACK. THE JACK HANDLE MAY

TURN RAPIDLY, OPENING THE RELEASE VALVE TOO FAST CAN CAUSE THE JACK TO LOWER

RAPIDLY, FAILURE TO HEED THESE WARNING MAY CAUSE SERIOUS INJURY OR DAMAGE.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 10

Visit us at www.tqbbrands.com.au

5. INSPECTION

• Prior to each use conduct a visual inspection checking for abnormal conditions, such

as cracked welds, leaks, and damaged, loose, or missing parts.

• The Jack should be maintained in accordance with the maintenance instructions

(Section 7). No alterations or modifications shall be made to this Jack.

• Inspections shall be performed in accordance with this owner’s manual.

• The jack must be inspected immediately if it is believed to have been subjected to

abnormal load or shock.

• Owners and /or operators should be aware that repair of this product may require

specialised equipment and knowledge (refer to maintenance section).

6. STORAGE

This jack should always be stored in a dry location on a level surface with the lift ram in

the fully lowered position.

7. MAINTENANCE

Monthly maintenance is recommended. Lubrication is critical to jacks as they support

heavy loads. Any restriction due to dirt, rust, etc, can cause either slow movement or

cause extremely rapid jerks damaging the internal components. The following steps are

designed to keep the jack well maintained and operational.

Binding: If the product binds while under a load, use equipment with equal or a larger

load capacity to lower the load safely to the ground After un-binding, clean, lubricate

and test that the equipment is working properly. Rusty components, dire, or worn parts

can be causes of binding. Clean and lubricate the equipment as indicated in the

lubrication section. Test the equipment by lifting without a load. If the binding

continues contact authorised repair facility.

Cleaning: if the moving parts of the equipment are obstructed, use a cleaning solvent or

a good quality degreaser to clean the equipment. Remove any existing rust, with a

penetrating lubricant.

Lubrication: this equipment will not operate safely without proper lubrication. Using

the equipment without proper lubrication will result in poor performance and damage to

the equipment. Some parts in this equipment are not self-lubricating, inspect the

equipment before use and lubricate when necessary. After cleaning, lubricate the

equipment using light penetrating oil or lubricating spray.

• Use a good quality lubricant on all moving parts.

• For light duty use lubricate once a month

• For heavy and constant use lubrication is recommended weekly.

• Never use sandpaper or abrasive material on these surfaces.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 11

Visit us at www.tqbbrands.com.au

Rust Prevention:

• Check rams and pump plungers on the power unit assemblies daily for any

signs of rust or corrosion.

• Without load lift the equipment as high as it goes and look under and behind

the lifting points. If signs of rust are visible clean as needed.

ONLY USE HIGH QUALITY HYDRAULIC FLUID – ISO68

To Add Oil:

1. Position the jack on level ground and

lower saddle.

2. Remover the oil plug.

3. Fill the oil case until oil level is just beneath the lower rim of the oil fill

hole.

4. Replace oil plug.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 12

Visit us at www.tqbbrands.com.au

To Replace Oil:

1. Position the jack on level ground and

lower saddle.

2. Open release valve by turning handle counter

clockwise.

3. Remove oil filler plug and the handle.

4. Turn the jack on its side so that old oil will drain from the oil fill hole.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 13

Visit us at www.tqbbrands.com.au

5. Fill the oil case until oil level is just

beneath the lower rim of the oil fill

hole.

6. Replace oil plug.

Lubrication: Periodically check the pump piston and ram for signs or rust or corrosion.

Clean as needed and wipe with an oil cloth. NEVER USE SANDPAPER OR ABRASIVE

MATERIAL ON THESE SURFACES.

8. SERVICE & REPAIR

Any jack found damaged in any way, or found to be worn or operates abnormally should

be removed from service until repaired by an authorised service agent. Owners and / or

operators should be aware that repair of this product may require specialised equipment

and knowledge. Only authorised parts, labels, decals shall be used on this equipment.

Annual inspection of the jack is recommended and can be made by an authorised repair

facility to ensure that your equipment is in optimum condition and that the equipment

has the correct decals and safety labels specified by the manufacturer.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 14

Visit us at www.tqbbrands.com.au

TROUBLESHOOTING

JACK

WILL

NOT

LIFT

LOAD

JACK

WILL

NOT

HOLD

LOAD

JACK

WILL

NOT

LOWER

POOR

JACK

LIFTING

JACK WILL

NOT LIFT TO

FULL

EXTENSION

CAUSE & SOLUTIONS

X

X

X

Release valve is not completely

closed (turn handle clockwise)

X

Air Supply inadequate

X

Weight capacity exceeded

X

X

Air is in the hydraulics. Purge air

from system

X

X

X

X

Low oil level. Add oil as required

X

Oil reservoir is overfilled: Drain

excessive oil. Lubricate moving

parts

X

Jack is binding or foreign

obstruction

X

X

X

Power unit malfunctioning.

Replace the power unit.

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 15

Visit us at www.tqbbrands.com.au

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 16

Visit us at www.tqbbrands.com.au

PARTS LIST

Part #

Description

QTY

Part #

Description

QTY

1-1

Snap Ring

2

2-23

Sealing Ring

1

1-2

Wheel

2

2-24

Nylon Gasket

1

1-3

Bolt

4

2-25

Copper Bush

1

1-4

Spring Washer

4

2-26

Gland Nut

1

1-5

Frame Right

1

2-27

Spring

1

1-6

Bolt

4

2-28

Bolt

8

1-7

Washer

4

2-29

Front Cover

1

1-8

Bolt

5

2-30

Cylinder Barrel

1

1-9

Spring Washer

4

2-31

Still Ball

4

1-10

Bolt

4

2-32

Cylinder Bolt

2

1-11

Washer

4

2-33

Cylinder Spring

1

1-12

Bed

1

2-34

Cylinder Washer

4

1-13

Bracket

1

2-35

Air Pump Core

4

1-14

Frame Left

1

2-36

Piston Core

1

1-15

Handle Socket

1

2-37

O-Ring

2

1-16

Bolt

1

2-38

Release Air Rod

1

1-17

Universal Joint

1

2-39

O-Ring

2

1-18

Split Pin

2

2-40

Piston Cover

1

1-19

Fixing Ring

1

2-41

Air Lock

1

1-20

Spring Washer

3

2-42

O-Ring

3

1-21

Bolt

3

2-43

Bolt

3

1-22

Drive Head A

1

2-44

O-Ring

2

1-23

Cover Plate

1

2-45

O-Ring

1

1-24

Spring Hanger

1

2-46

Rear Cover

1

1-25

Spring

2

2-47

Still Ball

2

1-26

Connect Block

1

2-48

Plug

2

1-27

Release Valve Rod

1

2

Air Valve Assembly

1

1-28

Bolt

1

3-1

Head

2

2-1

Snap Ring

1

3-2

Nut

4

2-2

Snap Ring

2

3-3

Spring Washer

4

2-3

O-ring

1

3-4

Flat Gasket

4

2-4

Screw

1

3-5

Fix Board

1

2-5

Piston Rod

1

3-6

U Bolt

2

2-6

Sealing Washer

1

4-1

Knob

1

2-7

O-ring

1

4-2

Pin

1

2-8

Snap Ring

1

4-3

Handle Sleeve

2

2-9

Still Ball

2

4-4-1

Rear Handle

1

2-10

Oil Filler Plug

1

4-4-2

Front Handle

1

2-11

Oil Plug

1

4-5

Sleeve

1

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 17

Visit us at www.tqbbrands.com.au

Part #

Description

QTY

Part #

Description

QTY

2-12

Valve Seat

1

4-6

Lock Lever

1

2-13

Spring

1

4-7

Pin

2

2-14

O-ring

2

4-8

Bolt

2

2-15

Bolt

1

4-9-1

Control Rod B

1

2-16

Block

1

4-9-2

Control Rod A

1

2-17

Still Ball

1

4-10-1

Convey Rod B

1

2-18

Release Valve Rod

1

4-10-2

Convey Rod A

1

2-19

Copper

2

4-11

Spring

1

2-20

Valve Body

1

4-12

Nut

1

2-21

Nylon Gasket

1

4-13

Drive Head B

1

2-22

Air Pump

1

4-14

Pin

2

Product Code: RLATJ20T

Made in China to TQB Brands Pty Ltd specifications Page 18

Visit us at www.tqbbrands.com.au

WARRANTY

Red Label products have been carefully tested and inspected before shipment and are

guaranteed to be free from defective materials and workmanship for a period of 12 months

from the date of purchase except where tools are hired out when the guarantee period is

ninety days from the date of purchase.

Should this piece of equipment develop any fault, please return the complete tool to your

nearest authorised warranty repair agent or contact TQB Brands Pty Ltd Warranty team –

warranty@tqbbrands.com.au.

If upon inspection it is found that the fault occurring is due to defective materials or

workmanship, repairs will be carried out free of charge. This guarantee does not apply to

normal wear and tear, nor does it cover any damage caused by misuse, careless or unsafe

handling, alterations, accident, or repairs attempted or made by any personnel other than the

authorised TQB Brands Pty Ltd repair agent.

This guarantee applies in lieu of any other guarantee expressed or implied and variations of its

terms are not authorised.

Your TQB Brands Pty Ltd guarantee is not effective unless you can produce upon request a

dated receipt or invoice to verify your proof of purchase within the 12 month period.

Consumer Guarantee

Our goods come with a guarantee that cannot be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund for a major failure and compensation for any

other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable quality and the failure does not amount to a

major failure.

Table of contents