SPX OTC 1540 User manual

© 2004 SPX Corporation

Sheet No.

Issue Date: Rev. B, 6/07/04

Form No. 525814

Parts List &

Operating Instructions

for: 1540

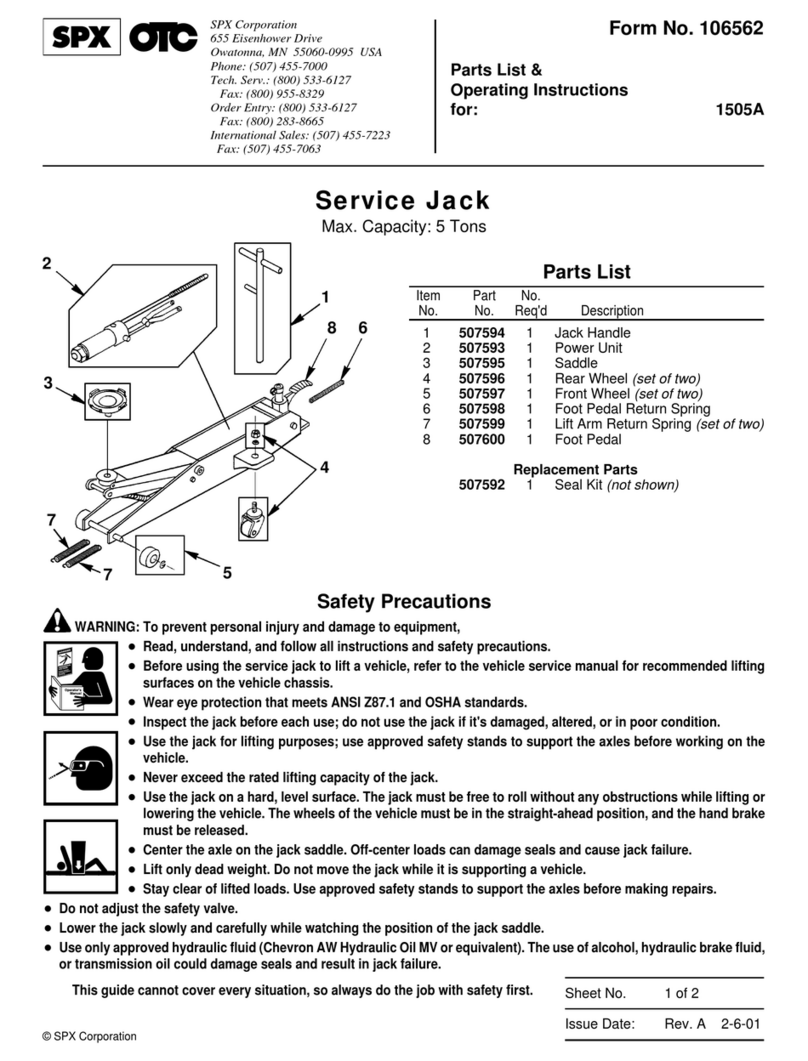

4-Ton Fork Lift Jack

Application: Servicing Fork Lift Machinery

SPX Corporation

655 Eisenhower Drive

Owatonna, MN 55060-0995 USA

Phone: (507) 455-7000

Tech. Serv.: (800) 533-6127

Fax: (800) 955-8329

Order Entry: (800) 533-6127

Fax: (800) 283-8665

International Sales: (507) 455-7223

Fax: (507) 455-7063

1 of 4

Specifications

Lifting Capacity: 8,818 lbs.

Lifting Range 13"

Min–Max Height 2.5"–16"

Package Size: 28 x 10 x 17"

Net Weight: 73 lbs.

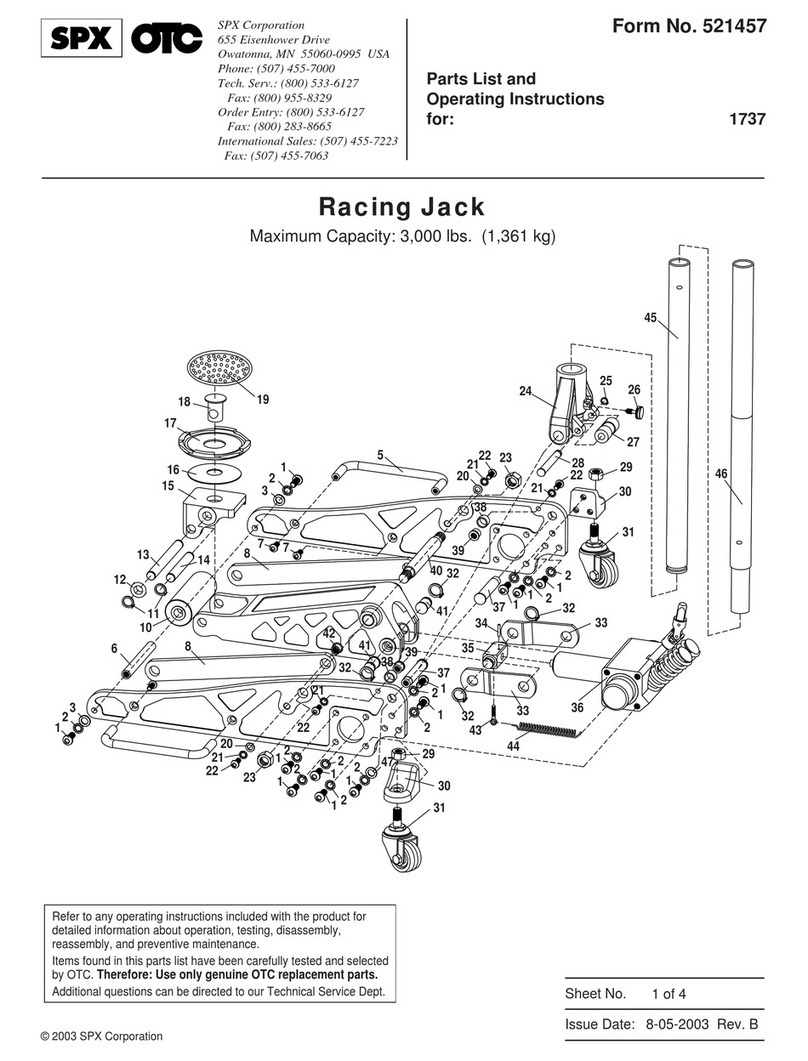

123

4

321

2

6

7

5

26

9

8

10

11

10

5

9

16

17

18

15

1413 12

8

19

63

64

63

37

62

43

37

37 38 39 38

36

35

34

33

32

31

28

27

252423

22 2120

26

28

29

65

30

37

44

45

46

47

45

21

20

55

56

61

60

59

58 57

48

49

43

50

28

51

52

53 54

15

Added translations.

Parts List & Operating Instructions Form No. 525814, Sheet 1 of 4, Back

Item

No. Qty. Description

1 2 Screw

2 4 Lock Washer

3 2 Trunnion

4 1 Frame 1

5 2 Screw

6 2 Washer

7 1 Axle

8 2 Snap Ring

9 2 Washer

10 2 Wheel

11 1 Frame 2

12 2 Screw

13 2 Lock Washer

14 2 Nut

15 2 Spacer

16 1 Pin

17 1 Saddle

18 1 Pin

19 1 Piston Rod Pad

20 2 Screw

21 2 Seal Ring

22 1 Screw

23 1 Spring

24 1 Ball Seat

25 1 Ball

26 1 Valve Block

27 1 Filter

28 3 Ball

29 1 Spring

30 1 Screw

31 1 Seal Ring

32 1 Pump

33 1 O-ring

34 1 Back-up Ring

35 1 Wiper

36 1 Plunger

37 6 Retaining Ring

38 2 Link Rod

39 2 Pin

43 2 O-ring

44 1 Oil Tank

45 2 O-ring

46 1 Port Ring

47 1 Cylinder

48 1 Piston Rod

49 1 Piston

50 1 Valve Seat

51 1 O-ring

52 1 Release Rod

53 1 Release Knob

54 1 Pin

55 1 Chain Hook

56 1 Chain

57 1 Handle Base

58 1 Ring

59 1 Pin

60 1 Handle

61 1 Grip

62 1 Pin

63 2 O-ring

64 1 Back-up Ring

65 1 Seal Ring

Parts Description

Item

No. Qty. Description

© 2004 SPX Corporation

Sheet No.

Issue Date: Rev. B, 6/07/04

Handle Kit

No. 525820

37 2 Retaining Ring

55 1 Chain Hook

56 1 Chain

57 1 Handle Base

58 1 Ring

59 1 Pin

60 1 Handle

61 1 Grip

62 1 Pin

Hydraulic Unit

No. 525821

18 1 Pin

19 1 Piston Rod Pad

20 2 Screw

21 2 Seal Ring

22 1 Screw

23 1 Spring

24 1 Ball Seat

25 1 Ball

26 1 Valve Block

27 1 Filter

28 3 Ball

29 1 Spring

30 1 Screw

31 1 Seal Ring

32 1 Pump

33 1 O-ring

34 1 Back-up Ring

35 1 Wiper

36 1 Plunger

43 2 O-ring

44 1 Oil Tank

45 2 O-ring

46 1 Port Ring

47 1 Cylinder

48 1 Piston Rod

49 1 Piston

50 1 Valve Seat

51 1 O-ring

52 1 Release Rod

53 1 Release Knob

54 1 Pin

63 2 O-ring

64 1 Back-up Ring

65 1 Seal Ring

Release Knob Kit

No. 525818

28 1 Ball

51 1 O-ring

52 1 Release Rod

53 1 Release Knob

54 1 Pin

Saddle Kit

No. 525822

16 1 Pin

17 1 Saddle

Seal Kit

No. 525817

21 2 Seal Ring

23 1 Spring

24 1 Ball Seat

25 1 Ball

27 1 Filter

28 3 Ball

29 1 Spring

31 1 Seal Ring

33 1 O-ring

34 1 Back-up Ring

35 1 Wiper

43 2 O-ring

45 2 O-ring

46 1 Port Ring

51 1 O-ring

63 2 O-ring

64 1 Back-up Ring

65 1 Seal Ring

Wheel Kit

No. 525819

8 1 Snap Ring

9 1 Washer

10 1 Wheel

Item

No. Qty. Description Item

No. Qty. Description

Parts List & Operating Instructions Form No. 525814

2 of 4

Hydraulic Unit Rebuild Kit

No. 525826

18 1 Pin

19 1 Piston Rod Pad

20 2 Screw

21 2 Seal Ring

22 1 Screw

23 1 Spring

24 1 Ball Seat

25 1 Ball

27 1 Filter

28 1 Ball

29 1 Spring

30 1 Screw

43 2 O-ring

45 2 O-ring

46 1 Port Ring

47 1 Cylinder

48 1 Piston Rod

49 1 Piston

50 1 Valve Seat

63 2 O-ring

64 1 Back-up Ring

65 1 Seal Ring

Jack Stop Kit

No. 525824

12 1 Screw

13 1 Lock Washer

14 1 Nut

Pivot Pins Kit

No. 525823

1 2 Screw

2 4 Lock Washer

3 2 Trunnion

5 2 Screw

6 2 Washer

7 1 Axle

15 2 Spacer

Pump Station Kit

No. 525825

28 1 Ball

31 1 Seal Ring

32 1 Pump

33 1 O-ring

34 1 Back-up Ring

35 1 Wiper

36 1 Plunger

37 4 Retaining Ring

38 2 Link Rod

39 2 Pin

Replacement Kits

Item

No. Qty. Description

Safety Precautions

CAUTION: To prevent personal injury and damage to equipment,

•Read, understand, and follow all instructions, including the ANSI B30.1 safety code for jacks. Before

using the fork lift jack to lift a vehicle, refer to the vehicle service manual for recommended lifting

surfaces on the vehicle chassis.

•Wear protective eyewear that meets the requirements of ANSI Z87.1 and OSHA.

•Inspect the jack before each use; do not use the jack if it’s damaged, altered, or in poor condition.

•Use the jack for lifting purposes only.

•A load must never exceed the rated lifting capacity (4 ton) of the jack.

•Only use the jack on a hard, level surface.

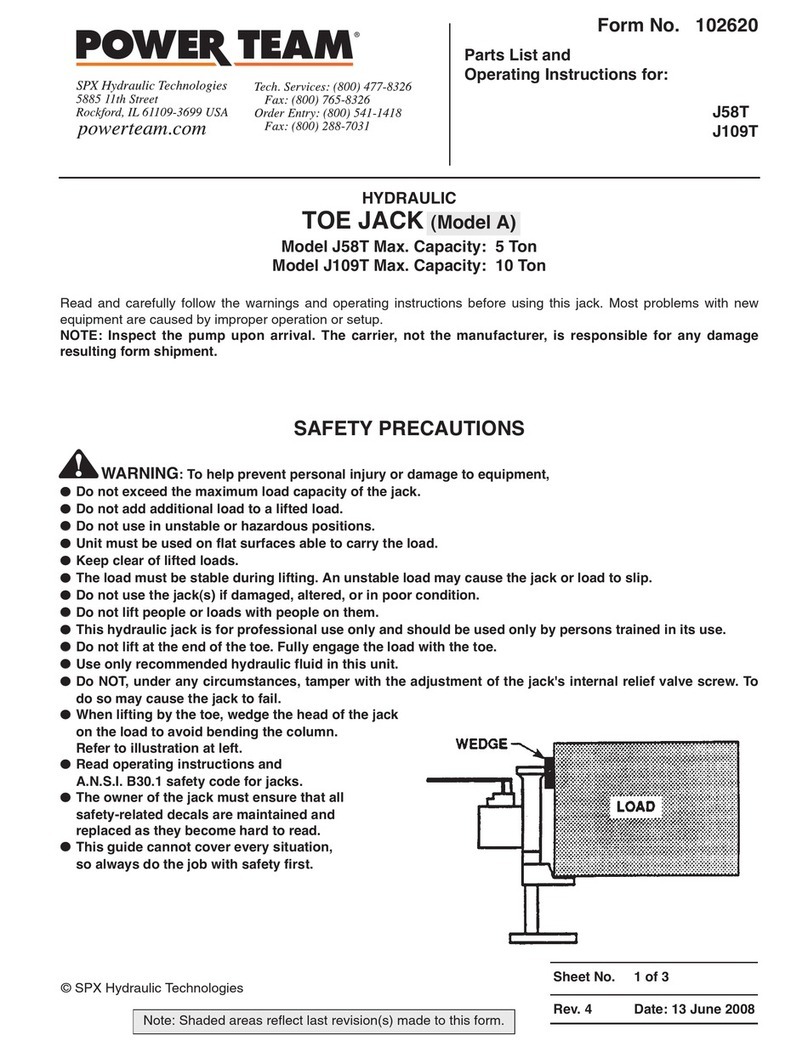

•Do not tilt the vehicle more than 15°when using the

serrated pad. Tilting the vehicle too far may result in

the jack kicking out suddenly and dropping the load.

•Stay clear of lifted loads and the scissor mechanism

of the jack.

•Placesupportstandsundertheaxlesbeforeworking

on the vehicle. See Figure 1.

•Do not modify the jack or use adapters unless

approved or supplied by OTC.

•Lower the jack slowly and carefully while watching

the position of the jack saddle. Do not drive the fork lift truck off the jack, or move the fork lift when

it is supported by the jack.

•Useonly approvedhydraulic fluid(Mobile DTE#13 orequivalent). Theuse ofalcohol, hydraulicbrake

fluid, or automatic transmission fluid (ATF) could damage seals and result in jack failure.

This guide cannot cover every situation, so always do the job with safety first.

Figure 1

Bleeding Air from the Fork Lift Jack

Air can accumulate within a hydraulic system during shipment or after prolonged use. This entrapped air causes

the jack to respond slowly or feel “spongy.” To remove the air:

1. Open the release valve (large knob on top) by turning the knob two full turns counterclockwise (CCW).

2. Pump handle slowly 5–10 times.

3. Close release valve.

If jack does not lift correctly, repeat steps 1 through 3.

Parts List & Operating Instructions Form No. 525814, Sheet 2 of 4, Back

© 2004 SPX Corporation

Sheet No.

Issue Date: Rev. B, 6/07/04

Operating Instructions

To raise the jack,

1. Insert handle into handle base.

2. Turn release valve (turn the knob clockwise until resistance is felt); do not over tighten.

To lower the jack,

1. SLOWLY turn the release valve counterclockwise. IMPORTANT: When lowering a fork lift truck, keep the rate of

lowering under your control. Do not lower the fork lift until the area is free of personnel, tools, and equipment.

Stay clear of the rear wheels on the jack; the wheels will move backward when the jack is lowered.

Recommended Method to Raise a Vehicle

1. Lower the forks on the fork lift. Remove any load. Clear personnel

from the area.

2. Carefully select a lifting point on the fork lift. It must be strong enough

to resist the lifting force without damage to the fork lift.

3. Cradle a support point in the notch at the end of the lift arm. See

Figure 2-B. Use the serrated pad to raise a vehicle with a flat

underside. See Figure 2-A.

CAUTION: To prevent injury or equipment damage,

•Use only the serrated lifting pad or the notch in the end of the

lifting arm as the means of lifting. Do not use any other part of

the jack as a lifting contact point.

•Do not tilt the vehicle more than 15°when using the serrated

pad. Tilting the vehicle too far may result in the jack kicking out

suddenly and dropping the load.

•Do not use cribbing under the jack or on top of the lift pad. The

jack must remain in direct contact with the floor; the lift pad or

notch must be in direct contact with the fork lift.

4.

Position the lift pad at least 3" inward toward the center of the vehicle

from the beginning of the flat surface. See Figure 2-A.

Lifting from the Side

1. Position the jack closer to the rear wheels than the front wheels to

maintain balance. See Figure 3. If the fork lift seems heavier at one

end, lower the jack and move it closer to the heavy end.

CAUTION: When lifting narrow fork lift trucks (less than 40"

wide) from the sides, the height between the floor and the bottom

of the raised tire cannot be more than one fourth (1/4) the tire tread

width.(Treadwidth is measured from centerline to centerline ofthe

tire treads.) If this height is exceeded, the fork lift truck could tip

over or the jack could drop the load. See Figure 4.

Example: If tread width is 36", the bottom of the vehicle tire may

never be more than 9" off the floor.

Figure 2

Figure 3

AB

3" min. flat

tread width

ht

Figure 4

3 of 4

Parts List & Operating Instructions Form No. 525814

Preventive Maintenance

IMPORTANT: The greatest single cause of failure in hydraulic units is dirt. Keep the fork lift jack clean and well

lubricated to prevent foreign matter from entering the system. If the jack has been exposed to rain, snow, sand,

or grit, it must be cleaned before it is used.

1. Store the jack in a well-protected area where it will not be exposed to corrosive vapors, abrasive dust, or any other

harmful elements.

2. Regularly lubricate the stem of the pump plunger with heavy grade machine oil.

3. To check the oil level, place the fork lift jack on level ground, and completely retract the ram. Remove the plug from the

oil filler hole. The oil level should be within 1/4" of the filler plug hole. If necessary, add approved anti-wear hydraulic

jack oil (Mobile DTE #13 or equivalent), and install the filler plug again. IMPORTANT: The use of alcohol, hydraulic

brakefluid, detergent motor oil, or automatic transmission fluid (ATF) could damage the seals and resultin jack

failure.

4. Inspect the jack before each use. Take corrective action if any of the following problems are found:

a. Cracked or damaged housing d. Scored or damaged piston rod

b. Excessive wear, bending, or other damage e. Loose hardware

c. Leaking hydraulic fluid f. Modified or altered equipment

Lifting from the End

1. Position the jack at the center of the fork lift truck. See Figure 5.

2. Chock the wheels at the opposite end of the fork lift.

CAUTION: To prevent injury or equipment damage,

•Do not lift from the end of the fork lift if the contact surface is

sloped or rounded, such as in the counter weight areas.

•When lifting 3-wheeled trucks, never lift the 2-wheeled end.

Figure 5

Parts List & Operating Instructions Form No. 525814, Sheet 3 of 4, Back

© 2004 SPX Corporation

Sheet No.

Issue Date: Rev. B, 6/07/04

Parts List & Operating Instructions Form No. 525814

Troubleshooting Guide

Repair procedures must be performed in a dirt-free environment by qualified personnel who are familiar with this equipment.

Trouble Cause Solution

Erratic action 1. Air in system

1. Refer to section titled "Bleeding Air from the

Fork Lift Jack."

2. Oil viscosity too high

2. Change to a lower viscosity oil.

3. Internal leakage in cylinder

3. Replace worn packings. Look for

excessive contamination or wear.

4. Cylinder sticking or binding

4.

Look for dirt, gummy deposits, leaks,

misalignment, worn parts, defective packings.

Jack does not lift 1. Release valve is open

1. Close release valve.

2. Low/no oil in reservoir

2. Fill with oil and bleed system.

3. Air-locked system

3. Bleed system.

4. Load is above capacity of jack

4. Use correct equipment.

5. Delivery valve and/or bypass

5. Clean to remove dirt or foreign matter.

valve not working correctly

Replace oil.

6. Packing worn out or defective

6. Repair power unit.

Jack lifts only partially 1. Too much or not enough oil

1. Check oil level.

Jack advances slowly 1. Air in system

1. Refer to section titled “Bleeding Air from the

Fork Lift Jack.”

2. Pump not working correctly

2. Repair power unit.

3. Leaking seals

3. Repair power unit or seals.

Jack lifts load, but doesn’t hold 1. Cylinder packing is leaking

1. Repair power unit or seals.

2. Valve not working correctly (suction,

2. Inspect valves. Clean and repair seat

delivery, release, or bypass)

surfaces.

3. Air-locked system

3. Bleed system.

Jack leaks oil 1. Worn or damaged seals

1. Repair power unit or seals.

Jack will not retract 1. Release valve is closed

1. Open or clean release valve.

Jack retracts slowly 1. Cylinder damaged internally

1. Send jack to OTC authorized service center

for repair.

2. Link section is binding

2. Lubricate link section.

4 of 4

Table of contents

Other SPX Jack manuals

Popular Jack manuals by other brands

Larzep

Larzep A10210 instruction sheet

Atlas Equipment

Atlas Equipment RJ-6000 Installation & operation manual

Motomaster

Motomaster 009-1535-4 instruction manual

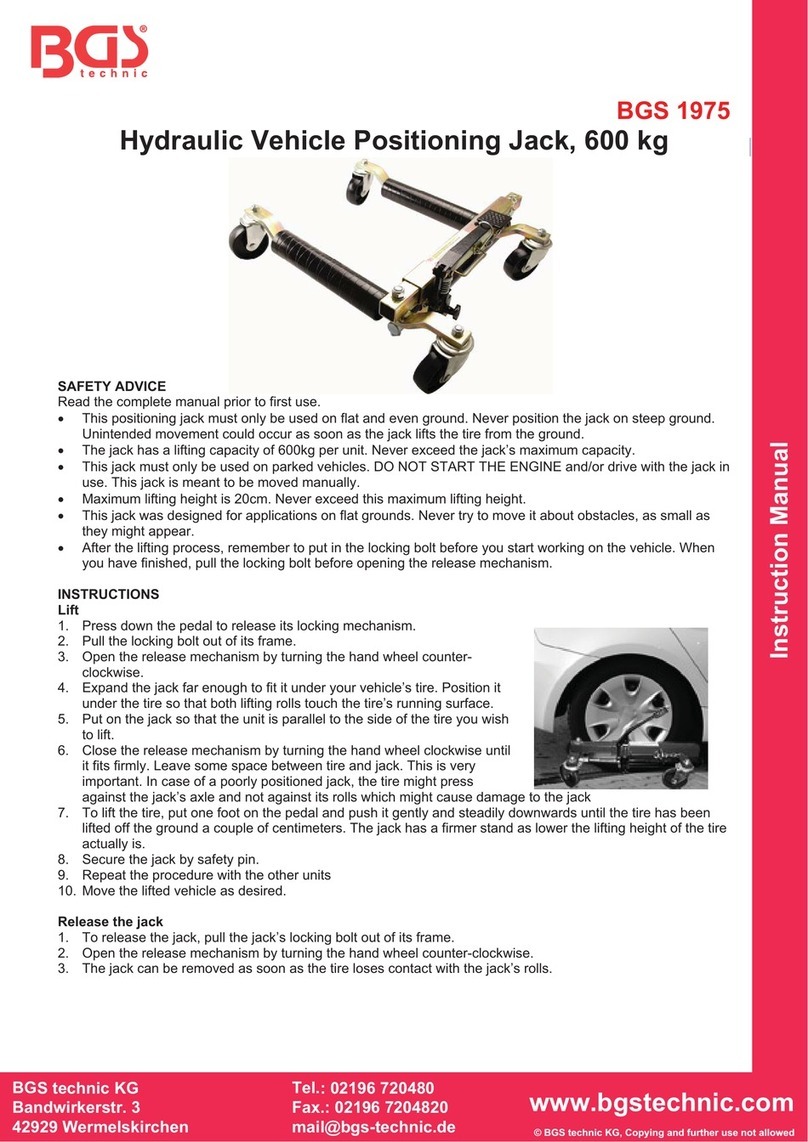

BGS technic

BGS technic 1975 instruction manual

LCI

LCI Power Tongue Jack installation manual

Matco Tools

Matco Tools MFJ354PA operating instructions