GENERAL DESCRIPTION

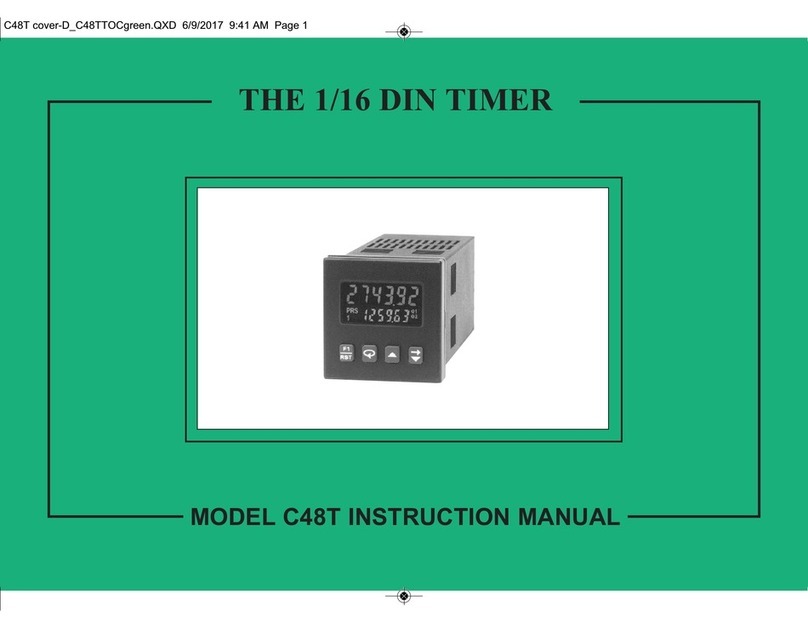

The Model C48 Timer is available in Single or Dual Preset models. The

C48T features a 7 segment, 2 line by digit reflective or backlit LCD display.

For the backlit versions, the main display line is red and shows the timer value.

The smaller secondary display line is green and can be used to view the preset

values or output time values.

The C48 Timer can be configured for a variety of different operating modes

to meet most timing application requirements. Twelve timing ranges are

available from thousandths of a second to hours and minutes. Decimal Points

are used to separate the time units (hours, minutes, seconds). Timing can be

cumulative or can reset and start upon each power cycle. “On Delay” or “Off

Delay”, “Single Shot”, and “Repetitive auto cycling” modes are all supported.

Four front panel push-buttons are used for programming the operating modes

and data values, changing the viewed display, and performing user

programmable functions, e.g. reset, etc. The C48T can be configured for one of

two numeric data entry methods, digit entry or automatic scrolling. The digit

entry method allows for the selection and incrementing of digits individually.

The automatic scrolling method allows for the progressive change of one

through all digit positions by pressing and holding the “up” or “down” button.

The C48 Timer has a Run/Stop Input, 3 programmable User Inputs, and a

programmable front panel function key. The Run/Stop and User Inputs can be

configured as sinking (active low) or sourcing (active high) inputs via a single

plug jumper. The following functions are available for user inputs and the front

panel function key:

The Dual Preset models are available with solid-state or Relay outputs. The

Single Preset model has a solid-state and relay output in parallel. All solid-state

outputs are available in a choice of NPN current sinking or PNP current

sourcing, open-collector transistor outputs.

The Timer can also be configured to Continue or Stop timing upon reaching

Preset. The display can be programmed to stop at the preset value (Reset to Zero

mode) or zero (Reset to Preset mode), or automatically reset to zero or preset

and hold. Once stopped, the timer can be restarted by manually resetting it, or

it can be programmed to restart when power is reapplied.

Optional RS485 serial communication capabilities allow for interrogation

and modification of the preset and timer values.

Optional programming software (SFC48) is available to program all unit

configuration parameters. The software allows unit configurations to be created,

uploaded, downloaded, and saved to a file for later use or multi-unit

programming.

The unit is constructed of a lightweight, high impact plastic case with a

textured front panel and a clear display window. When properly installed, the

front panel meets NEMA 4X/IP 5 specifications for indoor use. Multiple units

can be stacked horizontally or vertically. Modern surface-mount technology,

extensive testing, plus high immunity to noise interference makes the C48

Timers extremely reliable in industrial environments.

Safety Summary

All safety related regulations, local codes and instructions that appear in the

manual or on equipment must be observed to ensure personal safety and to

prevent damage to either the instrument or equipment connected to it. If

equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not use this unit to directly command motors, valves, or other actuators

not equipped with safeguards. To do so, can be potentially harmful to persons

or equipment in the event of a fault to the unit.

-1-

Reset Print Request

Store and Reset Change Display

Program Disable Reset Outputs

Store