Erratic Registration

Erratic registration is an indication of trouble in the system caused by air or dirt in the measuring

chamber. Do not try to correct this by recalibration of the flowmeter, but first check over the piping for

air leaks, clean the strainer and then, if the trouble has not been found, clean the flowmeter as

directed on pages 10 and 11. If this does not correct the trouble, check for faulty installation.

Over-registration is an indication of air, whereas under-registration is generally caused by dirt or

pipe scale in the measuring chamber, or the liquid bypassing the flowmeter in some manner.

Consistent Over or Under-Registration

When the flowmeter registers consistently either more or less than is delivered, the calibration

may be corrected in the following manner:

1. Remove four screws holding top cover and remove cover.

2. Lift and turn the change gear shifter (see Figure 5) in the direction indicated on the top of the

shifter.

3. There is a series of holes, marked A to H, in the plate

into which the guide pin enters at different settings.

Altering the setting by one hole changes the calibra-

tion approximately 17 cubic inches in 50 gallons.

Example:

Suppose the flowmeter consistently gives 34

cubic inches too much when it registers 50 gallons. After re-

moving the cover plate move the gear shifter 2 spaces to the

right

(from position E to position C)

to decrease the delivery

about 34 cubic inches in 50 gallons.

After changing the calibration always replace top cover,

making sure that the sheet steel housing on the sides and

back fits into the groove in the bottom edge of cover. Run a

small amount of liquid through the flowmeter before testing.

To prevent tampering, always reseal after calibration.

Note: For broader change gear requirements, refer to form TSG-310.

REGISTER MAINTENANCE

Register parts are such that only minor field repairs are advisable. When a register is in need of

repair or service other than that for which instruction is given here, it should be returned to an autho-

rized Actaris Neptune distributor for service.

To Remove Register From Flowmeter

Loosen the two clamp screws on lower front of the register. Lift the register off. On Preset

Models the valve linkage must first be disconnected. (Remove cotter pin and washer at valve end.)

When one register is removed and another substituted,

(1) Check the number of teeth on the change gears

(see

Figure 6)

. They must be the same as the gears on the old

register and on the same respective spindles. The num-

ber of teeth is stamped on each gear.To remove these gears,

close the split end of the spindle with a pair of pliers and pull

off the gear. After putting on a gear, spread the end of the

spindle slightly. (2) Make sure the position of the “Gear Shifter”

is the same on the new register as on the old one — each

hole is lettered for convenience.

To Clean Register Mask

The Register mask is made of plastic and requires spe-

cial treatment. Instructions for cleaning are given on next page:

Erratic Registration

Consistent Over or

Under-Registration

REGISTER

MAINTENANCE

To Remove Register

From Flowmeter

To Clean Register

Mask

Page 5

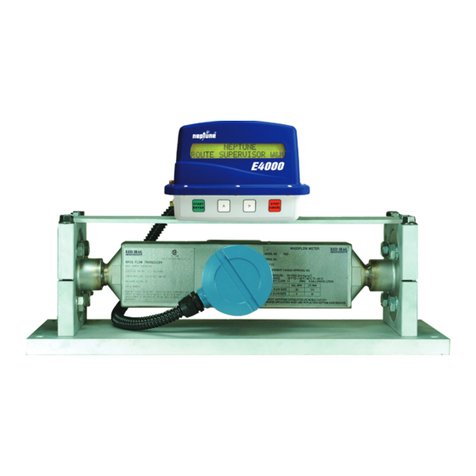

FIGURE 6

CHANGE GEAR ARRANGEMENT

CHANGE GEAR “R” CHANGE GEAR “S”

(ON “STD” SPINDLE)

GEAR

SHIFTER

FIGURE 5

GEAR SHIFTER ADJUSTMENTS