Page 1

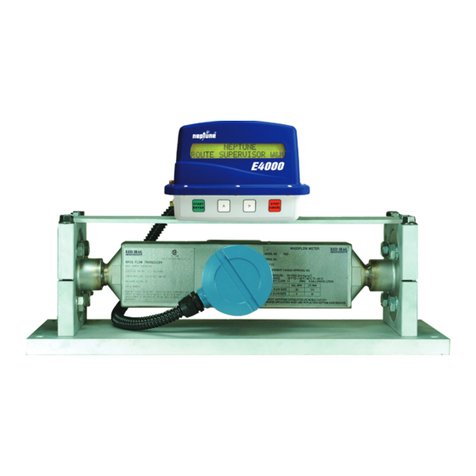

INSTALLATION

For correct installation of flowmeters, Red Seal Measurement is always available for

your assistance. Do not hesitate to call the nearest authorized distributor.

Plan the installation in such a way as to allow the strainer to be coupled directly to the inlet of

cleaned out.

Be careful to allow room for easy removal of the strainer basket.

removal of the greatest possible amount of air from the liquid before metering.

Use pipe cement or tape on male threads only.

anti-drain valve is recommended.

Experience has shown the need for a valve bypass connection to be installed around the

removed for repair.

line should be connected to a drip collecting tank or returned to liquid supply tank.

these directions were followed.

Inlet and outlet are clearly marked; do not install backwards.

on a platform support. Provide space for the removal of valve bonnet and internal parts on

Register.”

equipment is used.

INSTALLATION

Before Installing The Flowmeter

Piping

Air Vent Line

When Installing

After Installing