1. Remove cotter pins (E) from valve linkage.

2. Unscrew the outside register link lock nut (P) and remove connecting rod

(G).

3. Remove register link (N), rotate 1/2 turn and reassemble onto register as

described in appropriate valve adjustment instructions (Page 6).

4. Loosen two clamp screws on lower front of register up and turn register

180º.

5. Remove four handle housing assembly hex screws (C) and remove

handle housing assembly from valve.

6. Remove valve handle set screw (B) and slide handle off bushing.

Remove two cam retaining screws (not shown). Remove shaft seal

plug (D). Disassemble valve operating shaft and valve operating cam.

Reassemble valve operating shaft and install valve operating cam in

the reverse direction. Reinstall two cam retaining screws and shaft seal

plug. Reinstall housing assembly with valve operating cam acting on pilot

rod. Secure with four hex screws (C). Reassemble valve handle (A) on

knurled knob in position as shown for specic assembly.

After completing the above instructions, the valve linkage must be adjusted

in accordance with the procedure for the specic type valve as outlined on the

following pages.

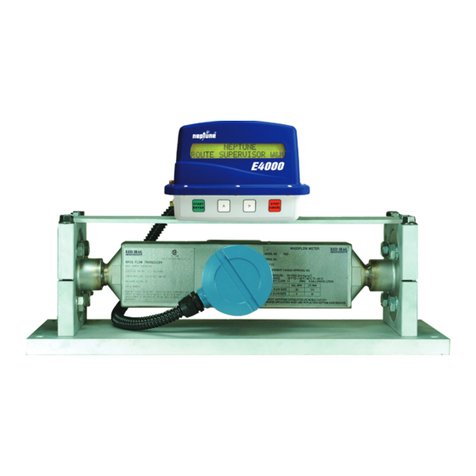

1” MP FLOWMETER WITH SINGLE TRIP AND DOUBLE

TRIP AUTO-STOP VALVE

Note: Before any adjustment of the Double Trip or Single Trip Auto-Stop Valve

is made, be sure that the Auto-Stop setting wheels indicate a quantity, other than

zero, to insure that the trip mechanism of the register is in proper position.

To Adjust Double Trip Valve Linkage With Valve At Outlet of Flowmeter

(See Figure 2)

1. Depress the emergency stop button on the register and turn the shaft (O)

clockwise (as viewed from rear of register.)

2. Assemble register link (N) on knurled knob in position as shown for

specic assembly. (See Figure 2). Arm should move an equal distance

each side of vertical center line (M) (Angle x=x).

3. Assemble one nut (P) on connecting rod (G) and the other end of the

connecting rod to the center hole in handle (A) using washers and cotter

pins (E).

4. Open valve all the way. Turn shaft (O) counter clockwise to latch up

mechanism. With valve held open, tighten nut (P) against register arm

link. Then assemble and tighten second nut at (P).

5. Depress the emergency stop button and allow the valve to close. At this

point the linkage between the valve and the register must be free. If it is

not, the above adjustments must be rechecked.

6. Set the register to deliver the minimum quantity and open the valve to run

product through the owmeter.

7. After the initial trip occurs the valve should close to the intermediate ow

position. This rate will vary depending on product metered. If the valve

closes too far, or all the way, adjust nuts (P) to provide additional rod

length.

1” MP FLOWMETER WITH

SINGLE TRIP AND DOUBLE TRIP

AUTO-STOP VALVE

Adjustment of 1” Double Trip

Auto-Stop Valve