3 of 28 ST-BARS-V1 RKA 03-02-2009

• The ST collector panels and FlowCon pump stations that we supply are compatible for the hot water

systems of most domestic houses. Other situations (including abnormally long primary circuits, space-

heating, et cetera, require special consideration).

• All dimensions between battens and/or fixing bars are measured from upper edge to upper edge, unless

stated otherwise.

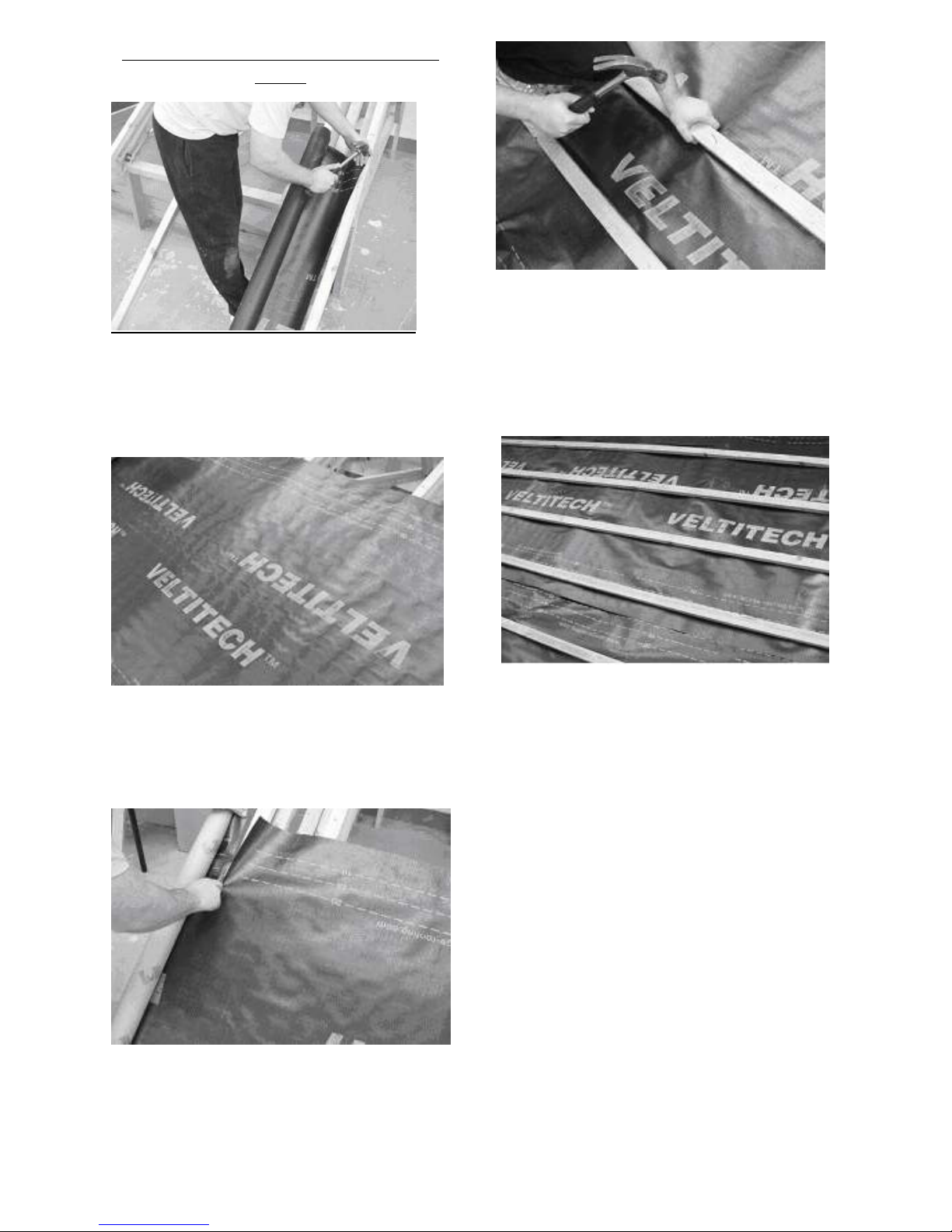

• The roof can be felted and battened as usual, but consult the table at item “6” before battening to

ensure that the proposed gauge is within an acceptable range.

• These instructions cover installation for pitched roofs between 30

o

and 45

o

rafter pitch with underlay properly

laid over rafters, and 50 x 25mm battens properly fixed over the underlay directly to rafters. For other roof

construction types, consult Redland Technical Solutions, as alternative bar fixings might be required.

HEALTH AND SAFETY, AND GENERAL REQUIREMENTS

• Lifting equipment is required for moving the panel, and lifting/positioning it onto the roof: -

o Panel weight (dry/unpacked): 120kg (ST 4), 180kg (ST 6).

o Panel dimensions (unpacked, overall excluding apron flashing):

2376mm wide x 2375mm high x 132mm deep (ST 4)

3369mm wide x 2375mm high x 132mm deep (ST 6)

• Ensure that all appropriate health and safety regulations are adhered to.

• The “FlowCon” pump stations (pump plus controller) that we supply can be connected to the electrical mains

via the included three-pin 13-amp plug (with 5-amp fuse fitted) directly to a mains socket. This does not

require Building Regulations Part P compliance. Alternatively, the connection can be made via an isolating

switch to a 5-amp fuse on the fuse board. This alternative must be in accordance with Part P of the current

Building Regulations (via a Building Regulations application or use of an accredited electrician).

• It is recommended that the plumbing installation be carried out, checked and commissioned by a competent

plumber who is suitably trained for solar thermal installations (BPEC or similar).

• The system must be filled, commissioned and tested in accordance with the pump station manufacturer’s

instructions and specification, including a pressure test to the specified pressure. Commissioning in

accordance with the CIBSE Commissioning Code M is recommended, and is recognised by the Building

Regulations.

• The system must be filled only with a liquid mix suitable for flat collectors.

• It is best to fill, test and commission the system, and put it into operation as soon as possible after the panel

is installed on the roof, in order to prevent damage by overheating. Our ST panels can be installed on the

roof and remain uncovered, not connected and not in operation, for a period not exceeding six calendar

months. We recommend, however, that such periods be minimised or that the panels be suitably covered

from direct sunlight for the duration, especially when planned in advance. Under the following conditions,

always keep suitably covered from direct sunlight: -

o Before installation on the roof.

o If the six-month period on the roof is about to expire before connection and commissioning can take

place and the system put into operation.

o If it is known in advance that the panels will be left on the roof unconnected, not commissioned and

not in operation for a period exceeding six months.

• Operating pressure is normally 1.5 to 4 bar (3 bar with the FlowCon B controller). Maximum for ST panels

and FlowCon B controller is 10 bar.

• Temperatures in excess of 150

o

C can be generated within the solar panel when there is no heat being

extracted, and this temperature can be conducted through the pipes and panel surfaces. Adjoining materials

and components (including insulation, pipes, supports, electrical connections) must be designed to withstand

such temperatures.

• Maximum sensor size is 6mm diameter x 45mm long (suits most appropriate sensors).