7

TESTING FOR LEAKS

Intake System Leak Testing

This test will find any leaks in ducting, charged air cooler, turbocharger, intake manifold,

throttle body, seals, gaskets, hoses, etc.

Seal off intake system by installing GM Graduated Adaptor or PowerSmoke™ Adaptor (see instructions)

into intake ducting after air cleaner box. Begin a 10-minute smoke cycle and pressurize entire system with

smoke at 5 PSI (0.35 BAR) while inspecting for leaks using provided Halogen inspection light. If no leaks

are present, increase pressure to 10 PSI (0.7 BAR) to observe leaks. Retest after repairs are performed to

confirm proper repair and seal.

Exhaust System LeakTesting

This test will find any leaks in exhaust tubing, clamps, flex pipe, muffler, diesel particulate

filter, turbocharger, exhaust manifold, etc.

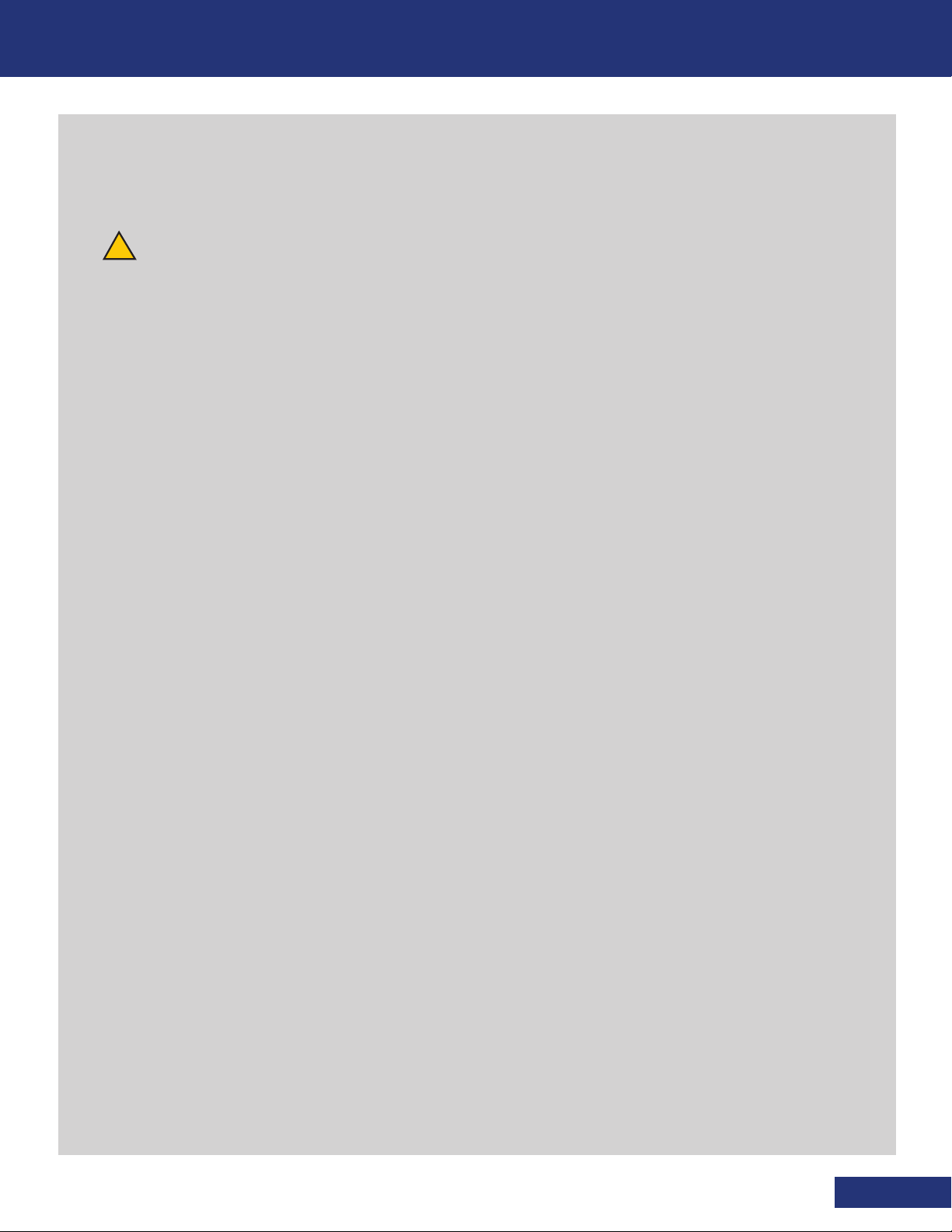

Seal off exhaust system by installing PowerSmoke™ Adaptor (see instructions) into exhaust pipe. If using

inside exhaust stack use the exhaust retention hoop to keep PowerSmoke™ Adaptor from falling inside

exhaust stack. Exhaust Particulate Filter or Catalytic Convertor may not allow visible vapor to pass through

because the particulates get trapped. In that case you may use block off coupler to convert PowerSmoke™

Adaptor into a block off adaptor while injecting smoke into the system using the Temperature Sensor Port

Adaptor, Pressure Sensor Port Adaptor or Oxygen Sensor Port Adaptor. These adaptors give you a great

amount of flexibility in testing all areas of the exhaust system. Retest after repairs are performed to confirm

proper repair and seal.

Combination Intake / ExhaustTesting

Some vehicles allow for a single procedure to test the entire intake and exhaust system at

one time.

Many engine systems can be tested from the air box to the tip of the exhaust completely in a single test. To

do so, install PowerSmoke™ Adaptor (see instructions) into intake ducting after air cleaner box AND install

PowerSmoke™ Adaptor (see instructions) into exhaust pipe. Convert PowerSmoke™ Adaptor in exhaust

system into a block off by installing block off coupler. Inject smoke into the intake system through the

PowerSmoke™ Adaptor. Pressurize entire system inspecting for leaks. Note: Complete system testing can

will occur when valve overlap is present or EGR valve is in open position. In cases where valve overlap

cannot occur or EGR may not be opened either manually or computer controlled, separate system testing

must be performed. Retest after repairs are performed to confirm proper repair and seal.

Cabin Leak Testing

Test for driver cabin exhaust / carbon monoxide infiltration, wind & water leaks.

Key on / Engine off, turn circulation fan to its highest speed making sure that the fresh air option is used

(NOT recirculate). If vehicle has dual air option, also initiate fan, selecting highest fan speed setting. The

circulation fan produces a positive cabin pressure. Make sure all windows and doors are completely

closed. Install SmokeMeister Wand (optional) to end of Smoke hose. Set test pressure to 3 PSI (0.2 BAR).

Make sure test is performed in a “still air” environment such as in a closed building. Using SmokeMeister

Wand (optional) proceed around vehicle cabin laying down fluffy smoke on all seams, seals and joints

looking for smoke vapor deflection from escaping air (leaks). Where smoke vapor is deflected is a visual

conformation of a leak. Seal leak and retest entire cabin for further leaks. To check for doghouse engine

cover leaks, turn off fans, install wand tip adaptor into wand, and inject smoke underside of doghouse

while someone inside cabin looks for leaks. Retest after repairs are performed to confirm proper repair

and seal.