Contents

Cautions for Use 3

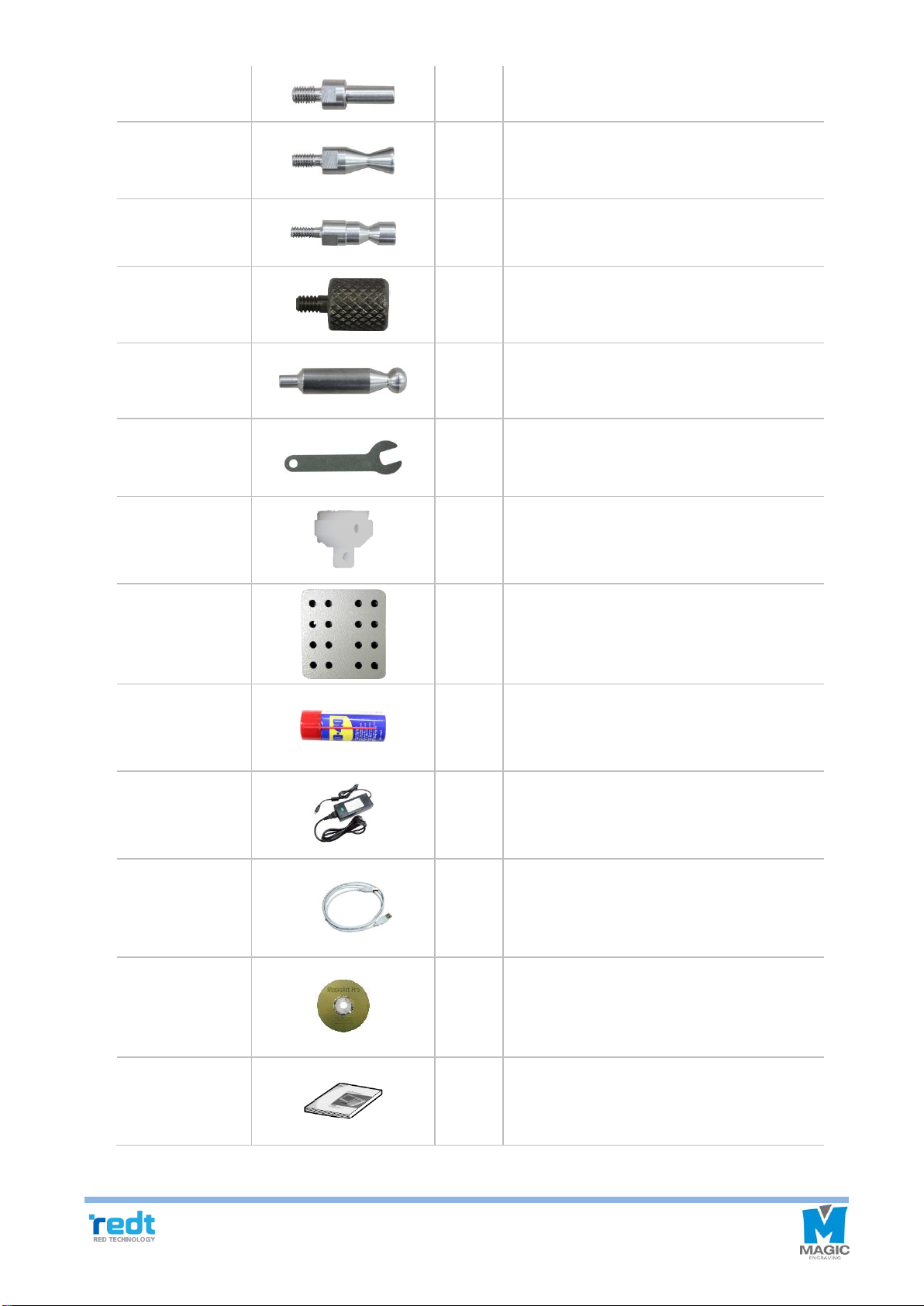

Product Parts and Installation 5

1) Parts and Accessories........................................................................................ 5

2) Specifications ..................................................................................................... 7

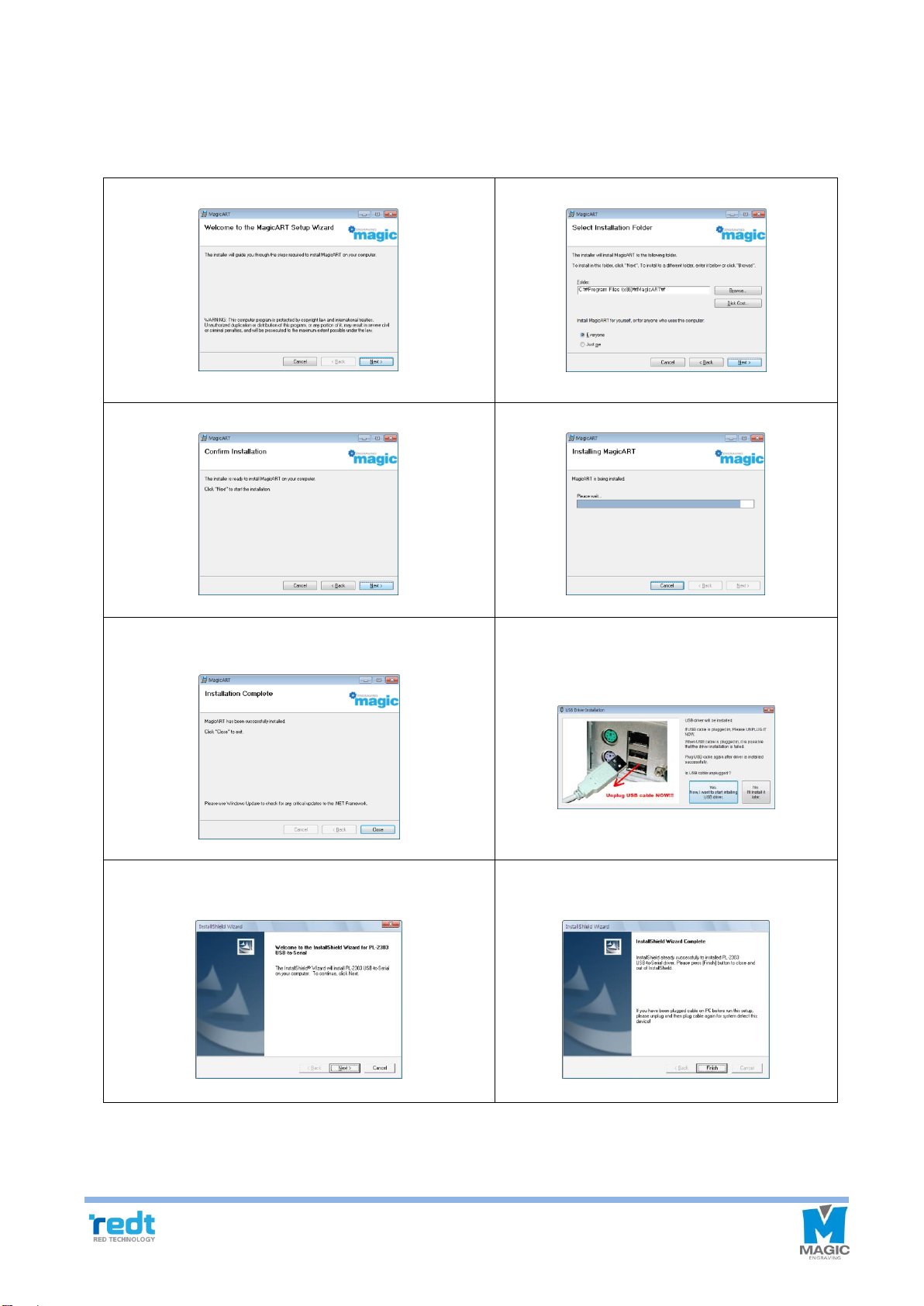

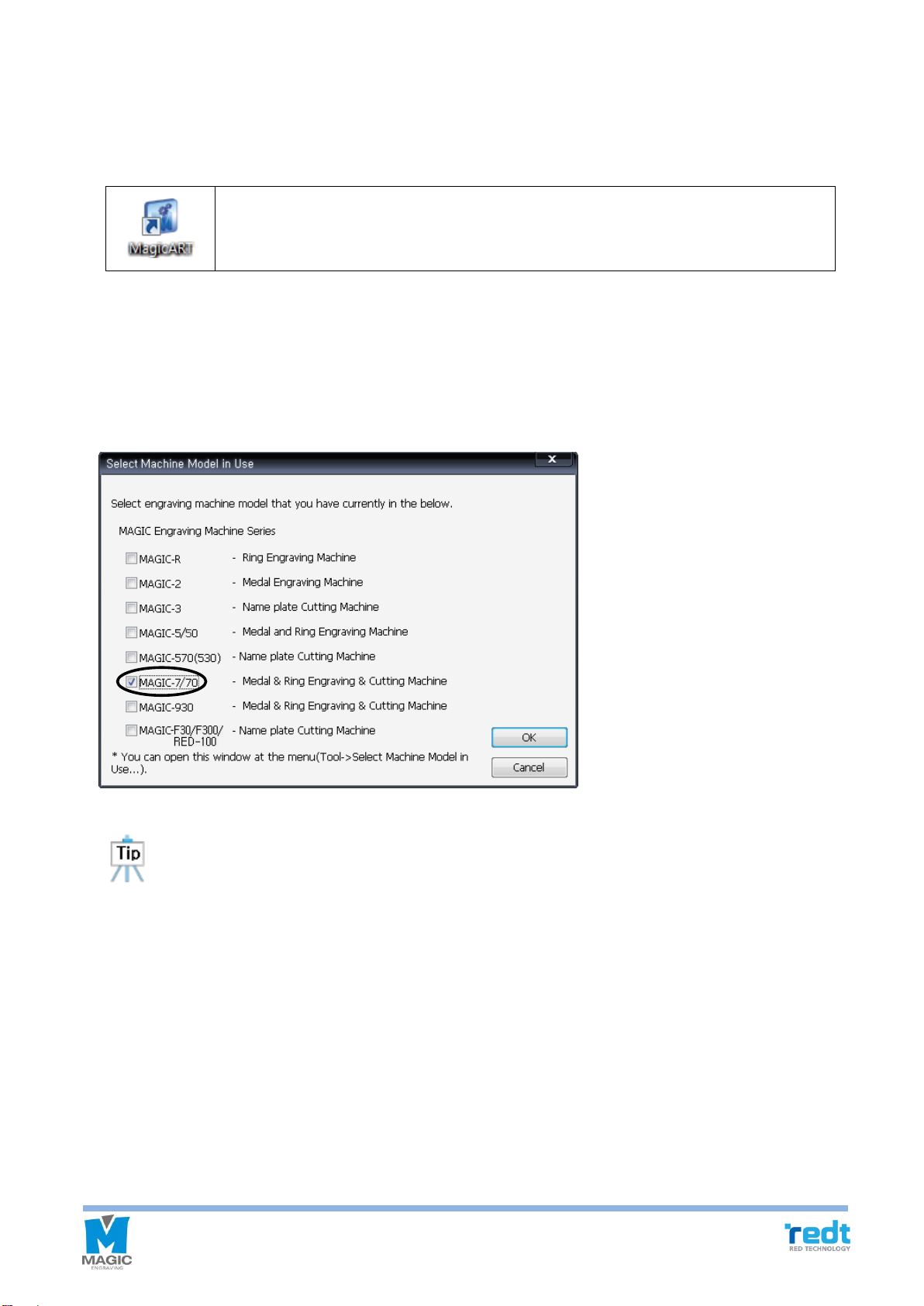

3) MagicArt S/W Program Installation .................................................................... 8

4) MAGIC-70 Installation ......................................................................................10

5) Description of MAGIC-70 ..................................................................................11

6) How to Use the Clamp ..................................................................................... 18

7) Changing Tools.................................................................................................25

8) Replacing the Spindle Belt ...............................................................................27

9) Tension .............................................................................................................27

Program Usage Description 29

1) Toolbar..............................................................................................................32

2) Registration information of Character object....................................................47

3) Registration information of rotation ..................................................................52

4) How to engrave for each tool path ...................................................................53

5) Create tool path................................................................................................54

5-1) Engraving option: Add/Delete/Edit ...........................................................56

5-2) Add/Delete/ Edit tool ................................................................................57

6) Registration information of tool path ................................................................ 58

7) Transfer NC data.............................................................................................. 59

Engraving Process 61

Engraving Process of Ring inner/outer Diameter

67

Character Cutting Process 77

Engraving by Using Nose 84

Drilling 87

Image Engraving 91

Pen Engraving Process 94

Curved Materials Engraving 98

Entering Characters placed in a Circle 99

Entering Characters in a Curve 102

Preview Font 103

Change Texts 104

Create Template 105

Saving as Design Sample 107

Auto Change of Serial Number 109

Add and Edit Picture 111

1) Add picture .................................................................................................111

2) Convert and edit picture file .......................................................................113