2

Any revisions must first be approved by the product designer. Version: 201808 Revision By: JST

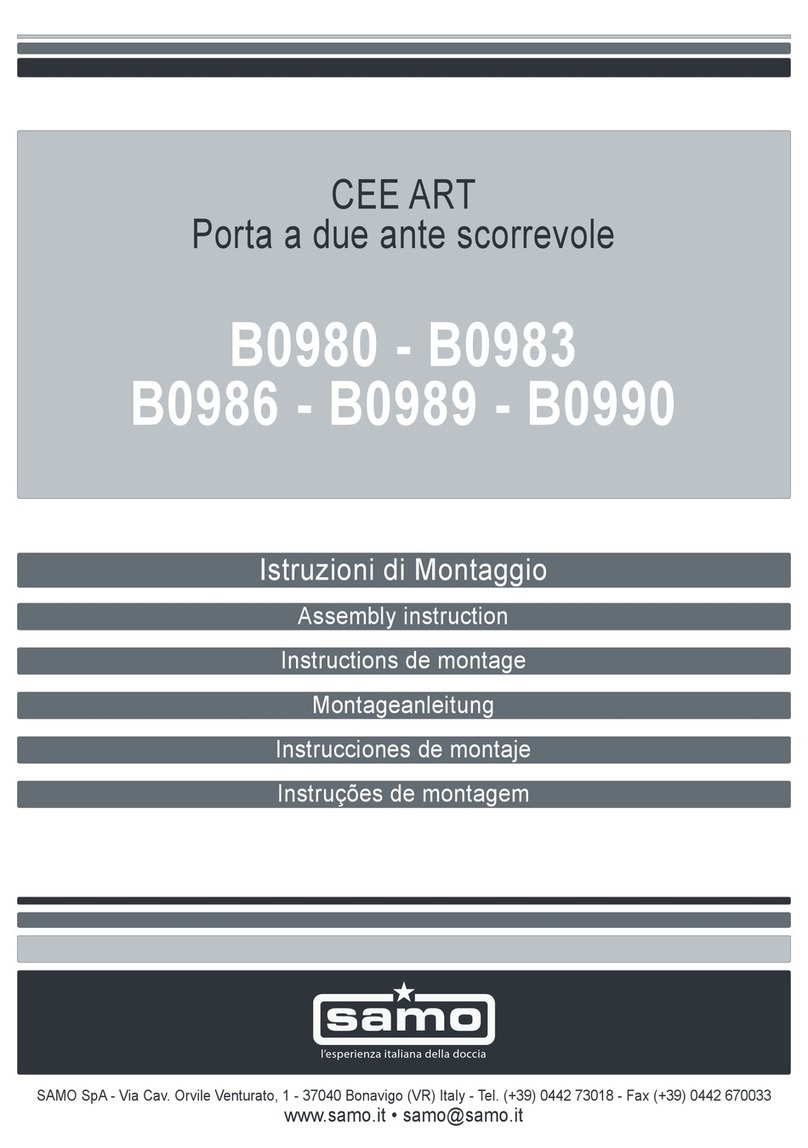

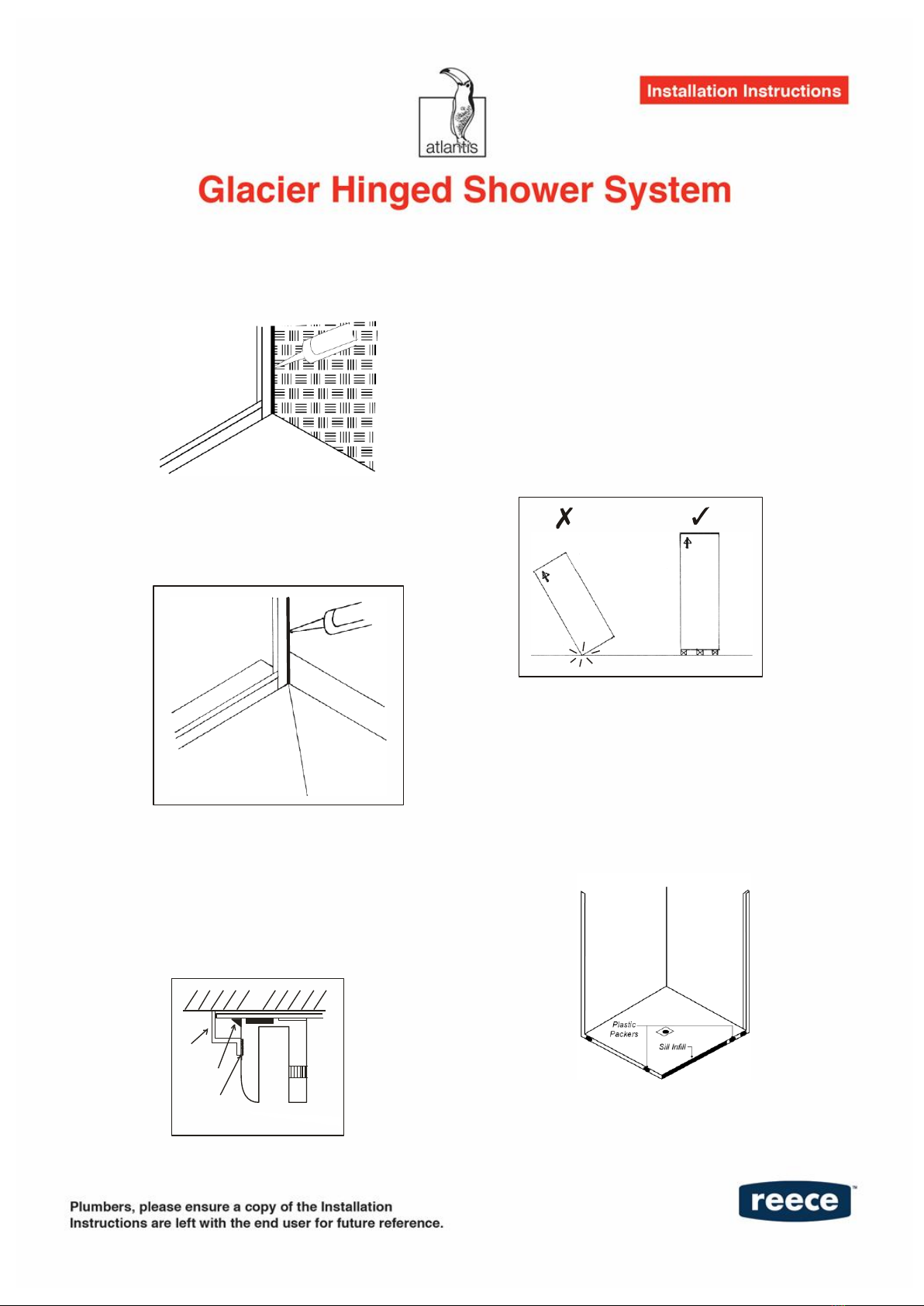

GLASS RECEIVER CHANNEL MUST BE

INSTALLED ONTO THE WATERPROOFING

BEFORE THE WALLS ARE TILED

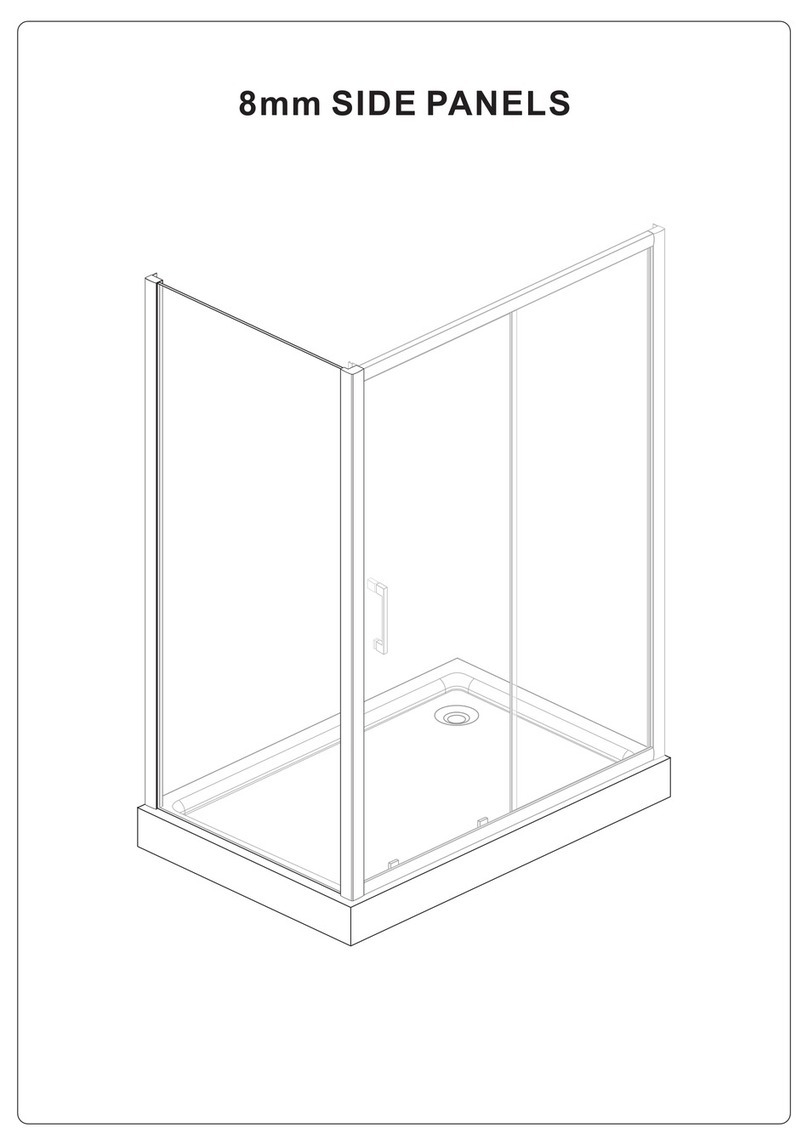

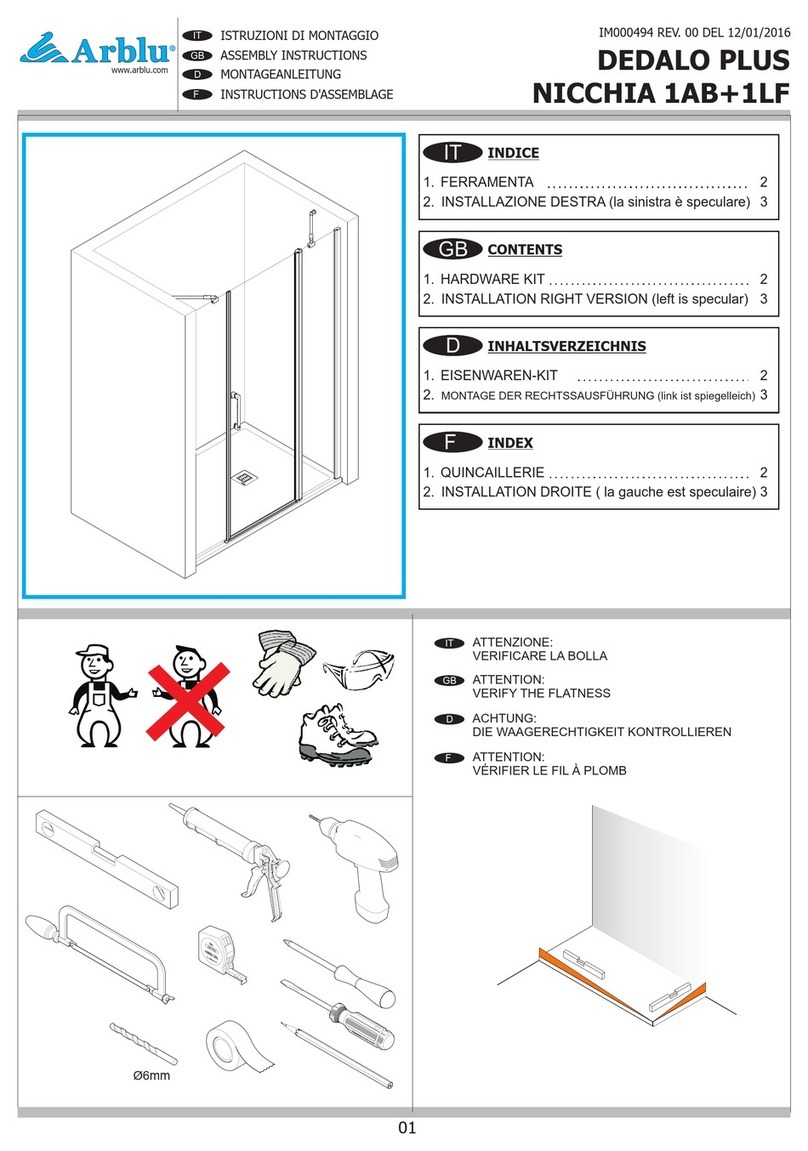

INSTRUCTIONS FOR

2 WALL SYSTEM

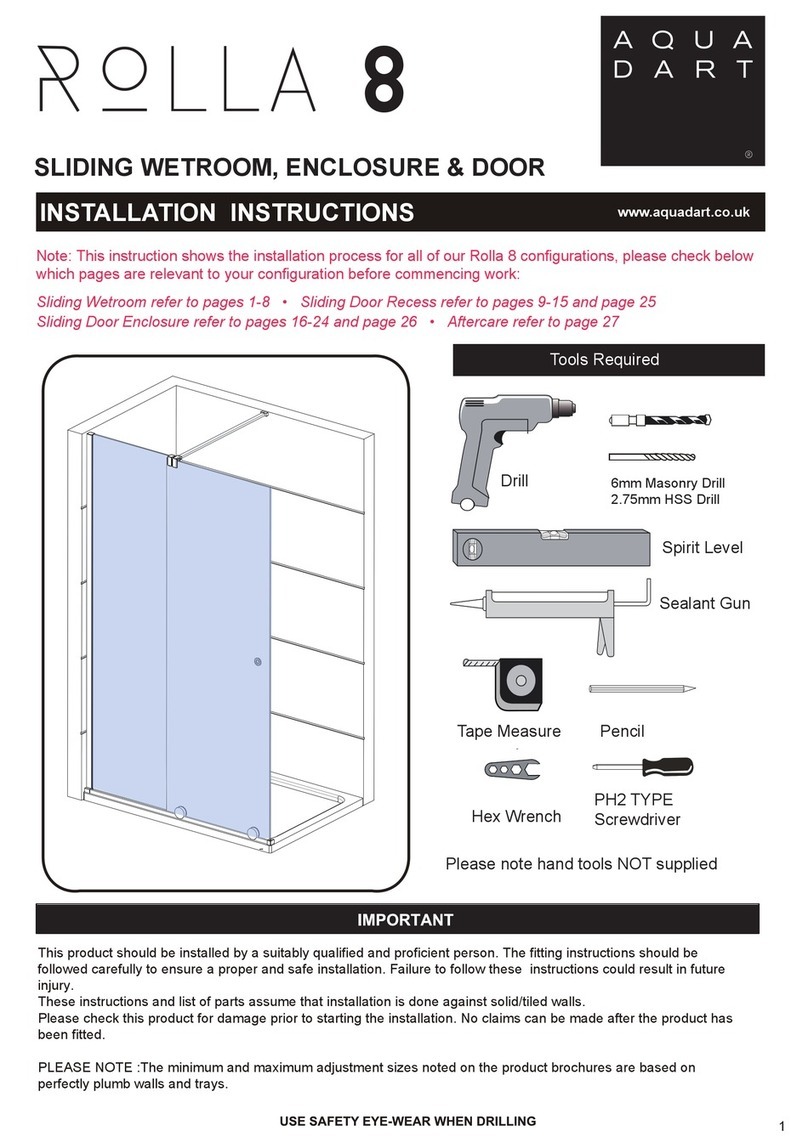

1. Choose door location.

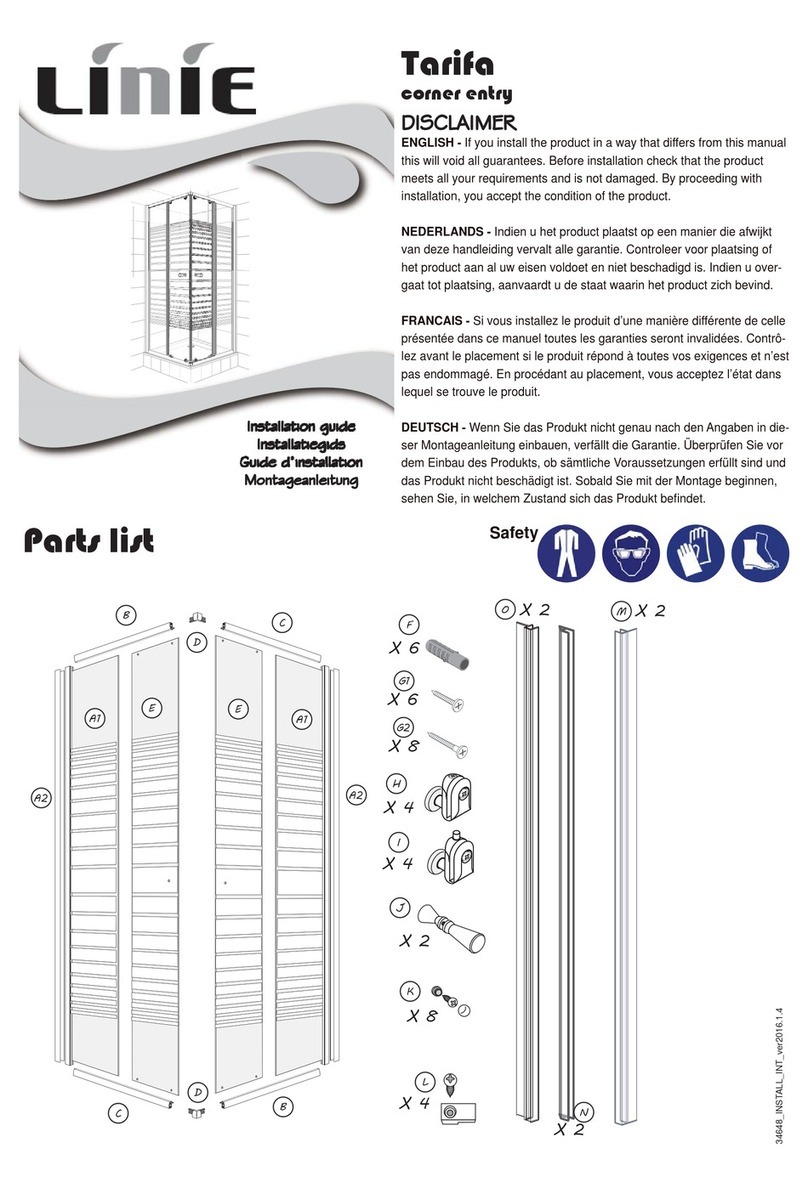

2. Position the glass receiver channels over

the base glazing channels. Mark the wall

to indicate where the wall channels are

plumb.

3. Mask two sides of wall channel before

applying white silicon. Apply a continuous

8mm bead of white silicon to full length of

wall channels in groove as indicated.

4. Ensure the glass receiver channels are

located firmly over the base glazing

channels. Locate the framing timber. Use

the 4mm drill bit to drill holes through the

glass receiver channels. Fix four screws

through the channels into the wall

framing (use wall plugs if required

supplied with wall channels).

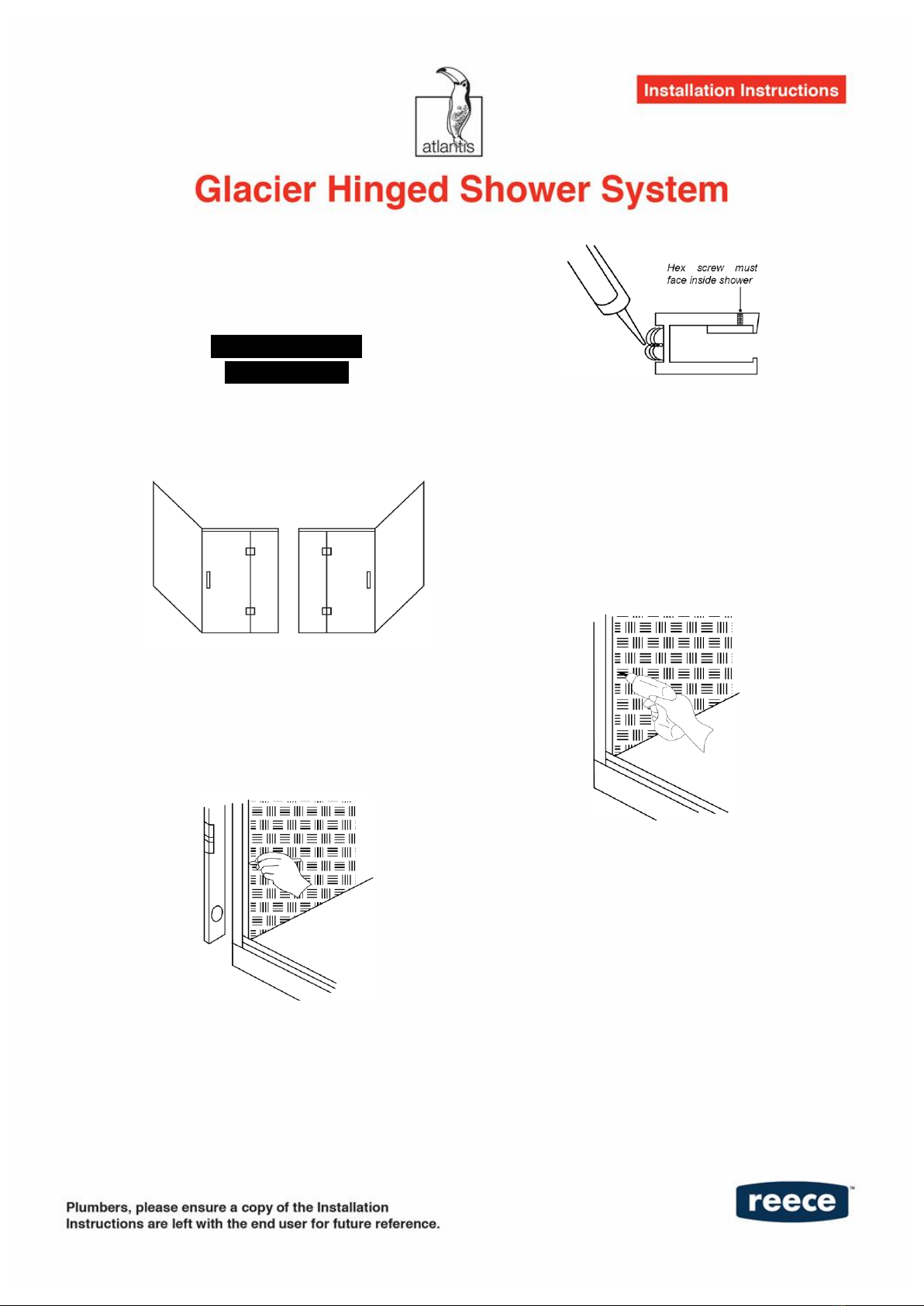

Apply a 10mm continuous bead of Sika

Artic White silicon, to the full length of

each wall channel. Silicon seal the join

where the wall and base channel will

intersect.