Fax: 909-287-2140 • Toll-free: 888-779-7333 • www.reedpumps.com

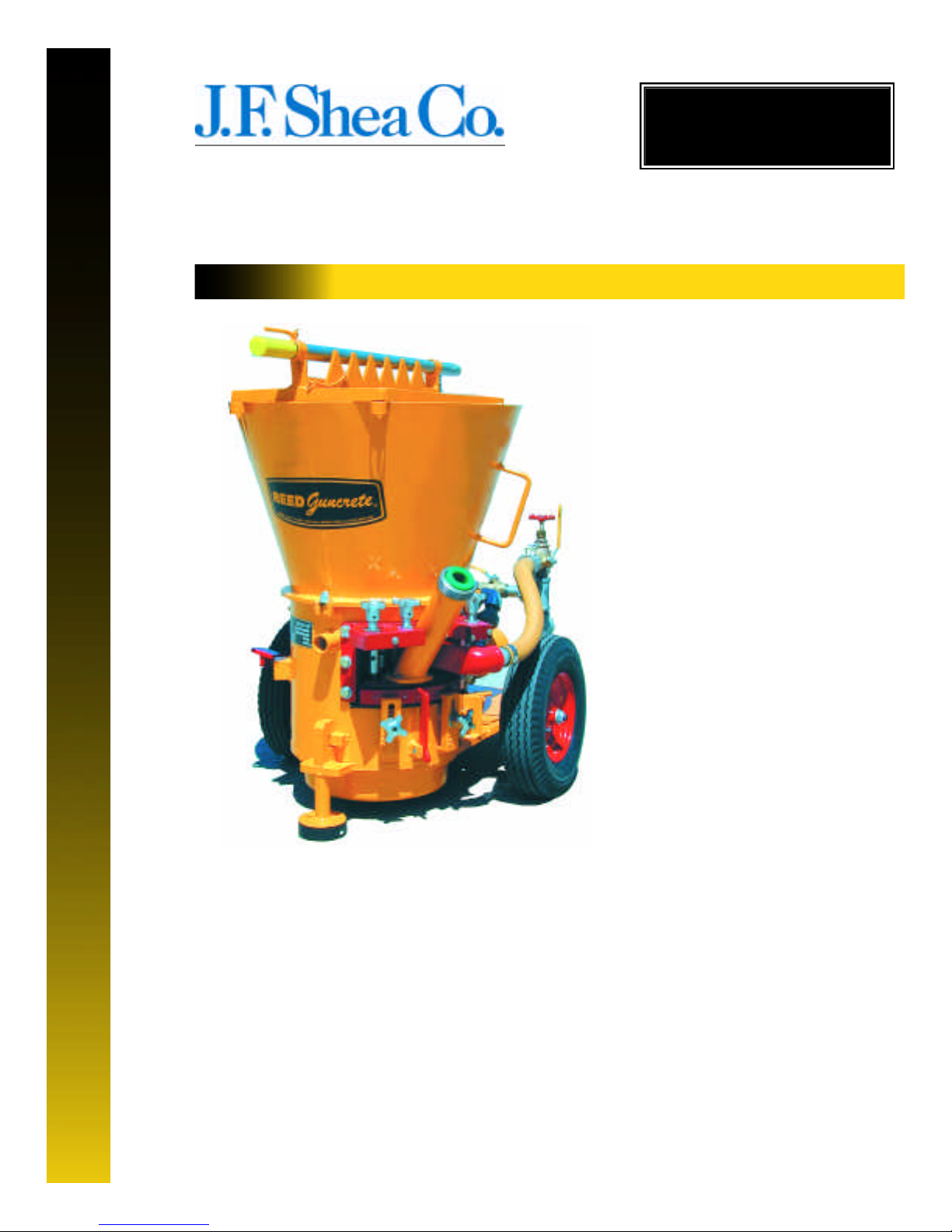

LOVA Guncrete MACHINE

Dry-Mix Gunite Machine

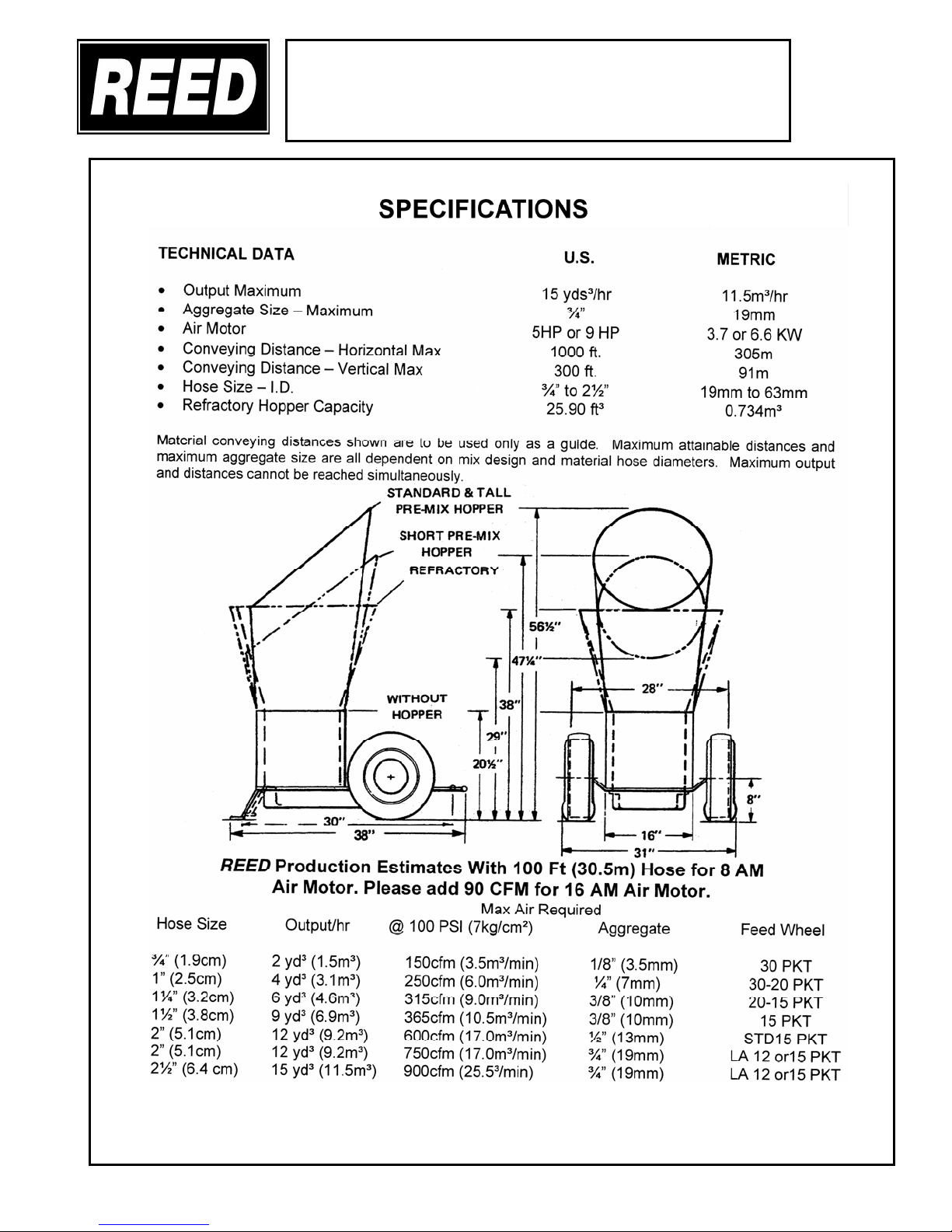

Subtract roughly 90 SCFM (2.5M/MIN) from air requirement if electric model is used.Additional air may be required depending on altitude and atmospheric pressure.

L.A. (Large Aggregate Feed Bowl)

eed Bowl, material, air system, nozzleman capability together determine maximum output.

ecifications subject to change without prior notice.

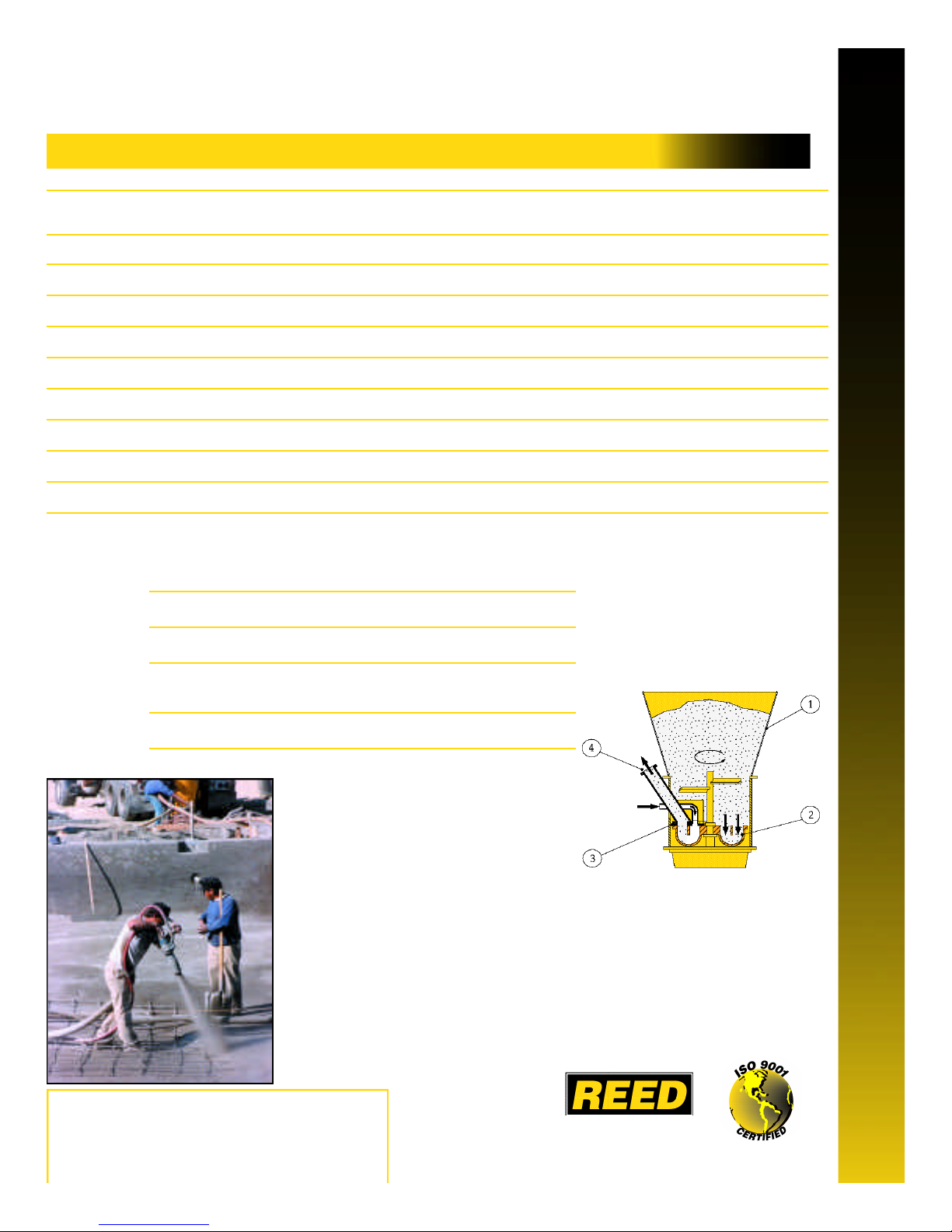

Operating Principle:

REED’s LOVAdry mix gun has

been using the same basic operating

principle for over 40 years.

1. The dry mix is fed through a

hopper into the pockets of the

rotary feed wheel.

2. The rotary feed wheel, driven

by a heavy-duty oil bath gear

drive, rotates the mix under

the conveying air inlet and

material outlet.

3. With the introduction of single source

compressed air, the mix is evacuated

from the feed wheel pockets and then

travels through the outlet.

4. The dry mix is then conveyed in sus-

pension through the dry mix hose to

the shotcrete nozzle where water is

introduced.

Feed Hose Maximum Air Compressor

Bowl Size Aggregate (Recommended Maximum Common

Pockets (I.D.) Size size at 100 psi) Output** Applications

30

3/4” (1.9cm) 1/8” 125 cfm (3.5m3/min) 8AM 2yd3/hr (1.5m3/hr) fine, detailed artistic-type work, rockscaping,

(3.5mm) 215 cfm (6m3/min) 16AM patch, repair.

30 1” (2.5cm) 1/8” 210 cfm (6.0m3/min) 8AM 2yd3/hr (1.5m3/hr) fine, detailed artistic-type work, rockscaping,

(3.5mm) 300 cfm (9.0m3/min) 16AM patch, repair.

21 11/4” (3.2cm) 1/4” 315-375 cfm (9-11m3/min) 8AM 5yd3/hr (3.8m3/hr) Refractory spraying, repair work, smooth finish

(7mm) 375-450 cfm (11-13m3/min) 16AM

21 11/2” (3.8cm) 3/8” 375-450 cfm (11-13m3/min) 8AM 6yd3/hr (4.6m3/hr) Refractory spraying, repair work, smooth finish

(10mm) 450-600 cfm (13-17m3/min) 16AM

20 11/2” (3.8cm) 1/2” 375-450 cfm (11-13m3/min) 8AM 8yd3/hr (6.1m3/hr) Civil Construction, Higher-Volume Refractory

(13mm) 450-600 cfm (13-17m3/min) 16AM spraying, smooth finish

15 2” (5cm) 1/2” 450-600 cfm (13-17m3/min) 8AM 12yd3/hr (9.2m3/hr) Civil Construction Concrete Spraying, Less

(13mm) 600-750 cfm (17-21m3/min) 16AM (Less Volume than with L.A. (Large Aggregate) system)

15 2” (5cm) 5/8” 450-600 cfm (13-17m3/min) 8AM 12yd3/hr (9.2m3/hr) Swimming Pool Construction, conveying

16mm 600-750 cfm (17-21m3/min) 16AM aggregate for backfill, civil construction

12 2” (5cm) 5/8” 450-600 cfm (13-17m3/min) 8AM 12yd3/hr (9.2m3/hr) Swimming Pool Construction (Less Volume than

16mm 600-750 cfm (17-21m3/min) 16AM with 21/2” System) (15 L.A. bowl provides smoother finish)

12 21/2” (6.3cm) 3/4” 600-750 cfm (17-21m3/min) 8AM 15yd3/hr (11.4m3/hr) Civil Construction Spraying, Highest Volume

19mm 750-900 cfm (21-26m3/min) 16AM 15yd3/hr (11.4m3/hr) (15 L.A. bowl provides smoother finish)

L0VA CONFIGURATIONS- Large Open Vertical-Feed Air-Powered

MODEL LOVA 8-4 LOVA 16-4

Maximum Horizontal ft 1000 1000

Conveying Distance m 305 305

Maximum Vertical ft 300 300

Conveying Distance m 91 91

Hopper Standard, Tall Pre-Mix, Standard, Tall Pre-Mix,

Short Pre-Mix Short Pre-Mix

& Refractory & Refractory

Gross Weight (Approx.) lbs 635 699

kg 288 312

Maximum theoretical performance shown above. Performance will vary depending on slump, mix design and delivery line diameter.

Specifications subject to change without prior notice.