OPERATING INSTRUCTIONS:

1. Prime the Pump.

A. From a Pressurized Supply

•Connectagardenhosetothegardenhosetting,

makingsuretheattachmentissnug.

•Attachthehighpressurehosetothequickconnecton

thepump.

•Withoutplugginginorturningonthepump,turnonthe

supplyofwaterandopentheoutletvalve.

•Oncewaterbeginstoowoutofthehigh-pressurehose

andtheairispurgedout,closetheoutletvalve.

B. From a Non-Pressurized Supply

•Connectagardenhosetothegardenhosetting,making

suretheattachmentissnug.

•Makesurethehoseendisnotrestingonthebottomor

sideofthesupplycontainer.Thiswillnotallowwaterto

ow,causingprimingandsuctionproblemswith

thepump.

•Primingthepumpiseasierifitisatequalorlowerheight

ofthesupplycontainer.

•Attachthehighpressurehosetothequickconnecton

thepump.

•Pluginthecordandturnonthepumpwiththeairbleed

off(primingvalve)open.Waterwillowfromthisvalve

oncethepumpbeginstoprime.Note: A hose can be

attached to the hose barb and run back to the water

supply if desired.

•Closetheairbleed-offvalveandthepumpwillquickly

prime.Makesuretheoutletvalveisopen.

•Oncewaterbeginstoowoutofthehigh-pressurehose

andtheairispurgedout,closetheoutletvalveandturn

offthepump.

Priming Tips:

A. Whenprimingthepumpfromanon-pressurizedsupply,

itisrecommendedtolltheinputgardenhosebefore

turningonthepump.

B. Theinputttingforthepumpisastandardgardenhose

connection.Whenthisattachmentismadeitisimportant

tomakesurethegardenhoseistightenedsnugglysothat

thepumpdoesnotsuckairthroughthelooseconnection.

Alooseconnectionwillmakethepumphardtoprime.

C. Theshorterthegardenhose,theeasieritistoprimethe

pump.Longhosestendtocollapsefromthesuctionofthe

pumpwhendrawingfromanon-pressurizedsystem,

restrictingow.

D. Useahosethatisrigidenoughsothatitdoesnotcollapse,

especiallywhendrawingwaterfromanon-pressurized

system.

2. Connect the High Pressure Hose to the system being

checked.

A. Ifthesupplywateriscomingfromapressurizedsystem,

itisrecommendedtollthesystemtobetestedwithwater

priortoturningonthepump.Thiscanbedonesimplyby

openingtheoutletvalveonthepump,allowingwaterto

owthroughthepumpandhigh-pressurehoseintothe

systembeingtested.Oncethesystemllsandpressure

beginstorise,proceedtothenextstep.

B. Non-pressurizedsystemsshouldbelledwithwaterpriorto

attachingthehigh-pressurehoseandturningonthepump,

ifatallpossible.Thiscouldspeedupthetestingprocess.

C. Theoutputttingattheendofthehigh-pressurehoseis

3/8”NPT.Anadaptormaybeusedtoattachthishoseto

thesystemthatisbeingpressuretested.

3. Setting the pressure.

A. Pluginthecordandturnonthepump(EHTP500)or

attach½”electricorcordlessdrilltoshaftonbackof

pump(DPHTP500).DPHTP500pumpcanbedrivenin

eithertheclockwiseorcounterclockwisedirection.

B. Runthepumpforafewsecondstobesureitis

pumpinguidintothesystem.Closethehighpressure

outletvalve.Pressurecanbeadjustedbyturningthe

pressureadjustmentknobonthesideofthepump.Turning

clockwisewillincreasethepressure.Turningcounterclock-

wisewilldecreasethepressure.

C. Whenthedesiredpressureindicatedonthepumpgauge

isreached,openhighpressureoutletvalveandrunthe

pumptopressurizethesystem.

4. Once the system reaches the desired pressure, close the

high pressure outlet valve and turn off the pump.

The gauge on the pump indicates the pump pressure and not

the test system pressure. A separate gauge for the test system is

required, and is not provided with these test pumps.

A. Oncethepumpreachesthesetpressure,itwillcontinue

torunbutthewaterwillowthroughtheAutomatic

Bypassandrecirculatethroughthepump.Itisnot

recommendedtorunthepumpinbypassmodeformore

thanacoupleofminutes.Oncethedesiredpressureis

reached,itisunnecessarytocontinuerunningthepump.

Closethevalve,turnoffthepumpandunplugthecord.

B. Thepumpisequippedwithavalveandhosewhichhas

acheckvalvetopreventbackow.Thecheckvalveonly

workswhenthethehoseisdetachedfromthepump.It

isrecommendedtollthesystembeingtestedthrougha

valvewhichcanbeshutforbackowpreventionaswell.

POWER HYDROSTATIC TEST PUMP OPERATING INSTRUCTIONS

2

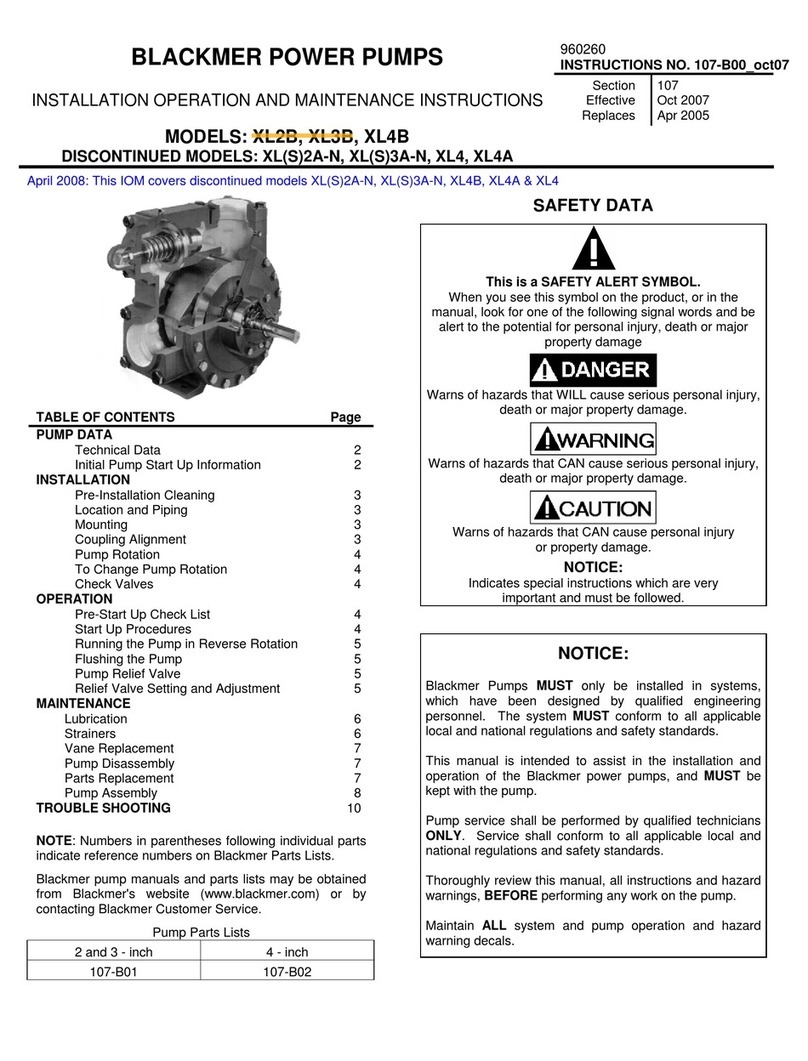

Item Description

1. PressureAdjustmentKnob

2. PressureGauge

3. GardenHoseFittingwithScreen

4. AirBleed-OfforPrimingValve

5. OutletHoseQuick-ConnectionandOutletValve

6. FrontCoverPlate

7. On/OffSwitch

8. AutomaticBypass

5. The system is now isolated.

A. Thehosecanquickdisconnectfromthepumpandremain

withthesystembeingtested,ifnecessary,sothatthe

pumpcanbeusedtotestanothersystemorstored.

1

2

3

4

5

6

7

8