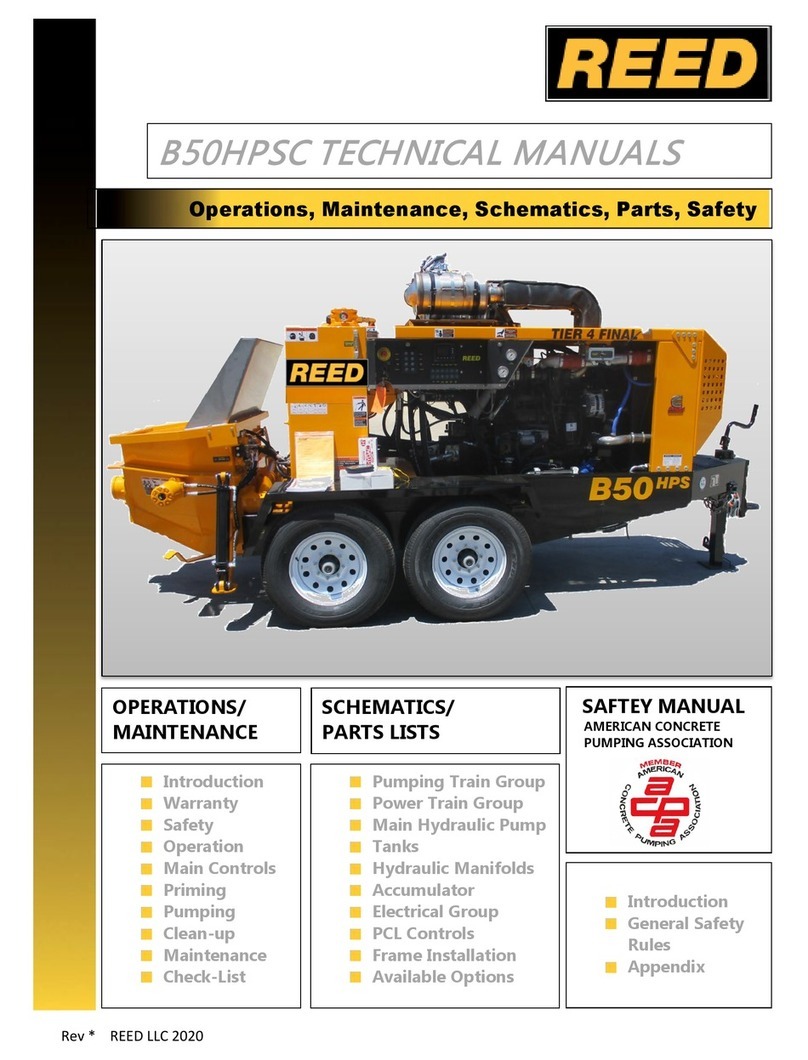

OPERATION and MAINTENANCE

Rev 1.2 1 of 80

INTRODUCTION............................................................................................................. 2

WARRANTY.................................................................................................................... 2

WARRANTY CLAIM FORM....................................................................................................................... 4

SAFETY .......................................................................................................................... 5

SAFETY ALERT SYMBOLS AND SIGNAL WORDS................................................................................. 5

LOCKOUT /TAGOUT................................................................................................................................ 6

GENERAL SAFETY GUIDELINES............................................................................................................ 7

SAFETY DECALS ..................................................................................................................................... 8

OPERATION ................................................................................................................. 17

OPERATOR QUALIFICATIONS.............................................................................................................. 28

SERIAL PLATE IDENIFICATION............................................................................................................. 29

ASERIES MAIN PANEL SERIAL IDENIFICATION ................................................................................. 30

B&C SERIES PANEL SERIAL IDENIFICATION...................................................................................... 31

CONTROLS ............................................................................................................................................ 32

PLC MAIN CONTROLS A-SERIES ............................................................................................................................... 32

PRODUCT DESCRIPTION ..................................................................................................................... 35

CONTROLS .................................................................................................................. 40

PLC MAIN CONTROLS B,C-SERIES ................................................................................................. 41

JOBSITE SET-UP................................................................................................................................ 50

PRIMING ................................................................................................................................................. 50

PREPARING FOR SYSTEM START-UP............................................................................................. 51

OPERATION OF CONTROLS A-SERIES ..................................................................... 52

OPERATION OF CONTROLS B&C-SERIES................................................................ 54

RECOMMENDED MAINTENANCE PRACTICES................................................................................... 55

GENERAL MAINTENANCE AREAS ....................................................................................................... 56

WHEEL AND TIRE SAFTEY .............................................................................................................. 59

TRAILER RECOMMENDED MAINTENANCE ........................................................................................ 60

LUBRICATION......................................................................................................................................... 62

COMPONENT REPLACEMENT ............................................................................................................. 72

PUMP MAINTENANCE SCHEDULE AND CHECKLISTS ...................................................................... 73

NOTES.......................................................................................................................... 80

J. SLACK

J.SLACK